Updx series, Blower temperature switch testing – Bradford White UPDX2-75T6FRN User Manual

Page 23

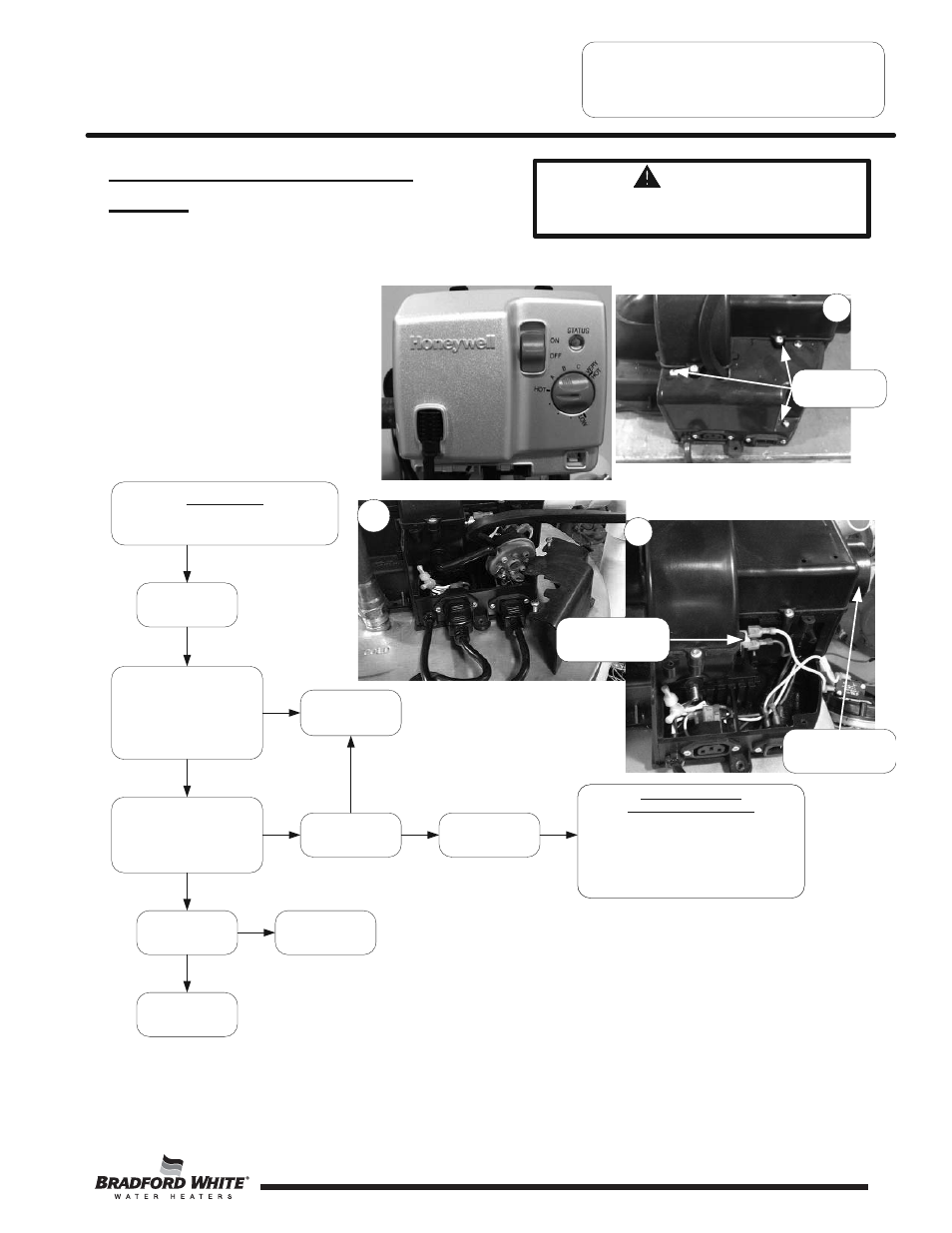

UPDX SERVICE PROCEDURE V

Blower Temperature Switch Testing

and Replacement

Blower Temperature Switch

Testing

WARNING

115 volt potential exposure. Use caution

to avoid personal injury.

Disconnect wire leads to

switch. Using a multi-meter

set to the ohms setting, is

there continuity between the

switch terminals?

Switch OK

Cool switch to

below 125°F.

N

Y

Switch Setting

Opens on rise @ approximately 155°F

Auto resets on fall @ approximately 128°F

Step 1.

Position gas control power switch

to the “OFF” position.

Step 2.

Remove the three screws

(Phillips screw driver) from

control access cover on

blower and remove cover

(see photos 18 and 19).

Step 3.

Locate blower temperature

switch (see photo 20).

Reconnect wire leads and

observe heater operation. Do

exhaust gas temperatures rise

to or above 175°F?

Replace switch

(see page 24).

Y

N

Do switch contacts

open?

Do switch contacts

open?

N

Y

Replace switch

(see page 24).

N

Y

Exhaust

temperature is too

hot.

Common causes for

high exhaust temperature

1. Vent length is below minimum allowable.

2. Vent diameter not to specification.

3. Restricted dilution air inlet.

4. Missing or deteriorated flue baffle.

5. Gas pressure is out of specification.

6. Excessively high ambient temperatures.

Blower Temperature

Switch Location

20

Air Mixing Inlet

Page 23

UPDX Series

Common causes for

high exhaust temperature

1. Vent length is below minimum allowable.

2. Vent diameter not to specification.

3. Restricted dilution air inlet.

4. Missing or deteriorated flue baffle.

5. Gas pressure is out of specification.

6. Excessively high ambient temperatures.

Gas Control shown in the “OFF”

Position

18

Control Access

Cover Screws

19

23