Feed table chain adjustment, Roll procession adjustment, 5 roll procession adjustment – B&C Technologies IM Series Industrial Ironer User Manual

Page 61: 5 feed table chain adjustment

Table 5.4: Roll to Roll Tension Chart

Ironer Size

Belt Size

Module Numbers

Deflection

Force

mm

mm

in

N

lb

2x800

3150

1 to 2

13

1/2

12-18

3.6-5.4

3x800

3150

1 to 2

13

1/2

9-13

2.0-2.9

3150

2 to 3

13

1/2

16-22

3.6-4.9

2x1200

4000

1 to 2

16

5/8

13-19

2.9-4.2

3x1200

4000

1 to 2

16

5/8

15-20

3.3-4.5

4000

2 to 3

16

5/8

26-39

5.8-8.7

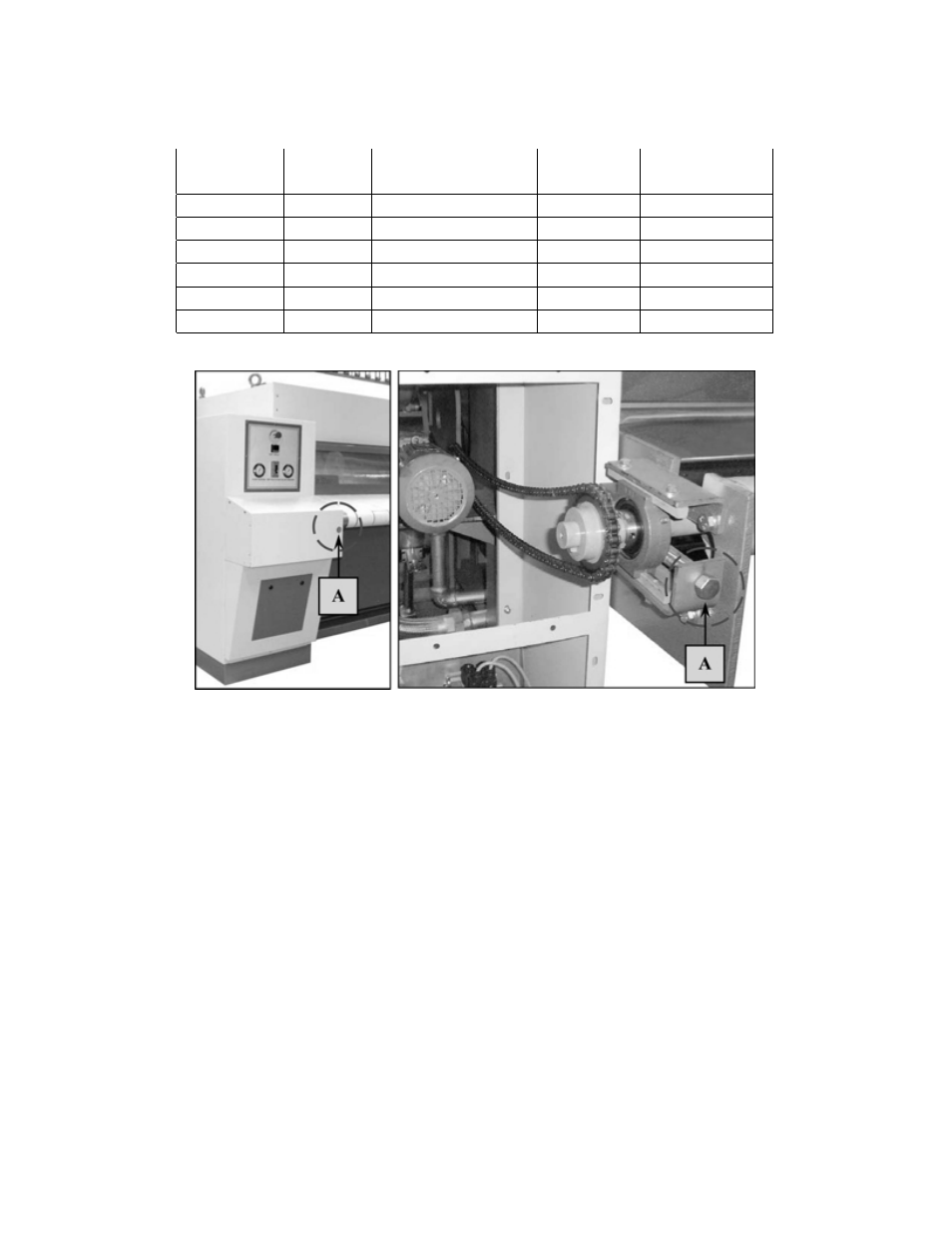

Figure 5.11: Infeed Belt Tension Adjustment

5.4.5

Feed Table Chain Adjustment

To properly tension the infeed belts, locate the access hole on either side of the infeed table (see

figure 5.11 on page 51). To tighten the infeed belts, rotate the bolts on both sides clockwise. To

loosen the infeed belts, rotate the bolts on both sides counterclockwise.

5.5

Roll Procession Adjustment

The rolls on a multi-roll ironer must rotate at ever increasing rates through the ironer for best

quality. This is accomplished by adjusting each roll’s speed relative to the previous roll. This

speed difference is small but of utmost importance. Too much procession, and the sheets will

be overly stretched and guide tapes will be frequently damaged. Too little procession will cause

wrinkling of the goods and feeding problems. Adjusting the procession follows these basic steps:

51