B&C Technologies IM Series Industrial Ironer User Manual

Page 133

7

INSTALLATION

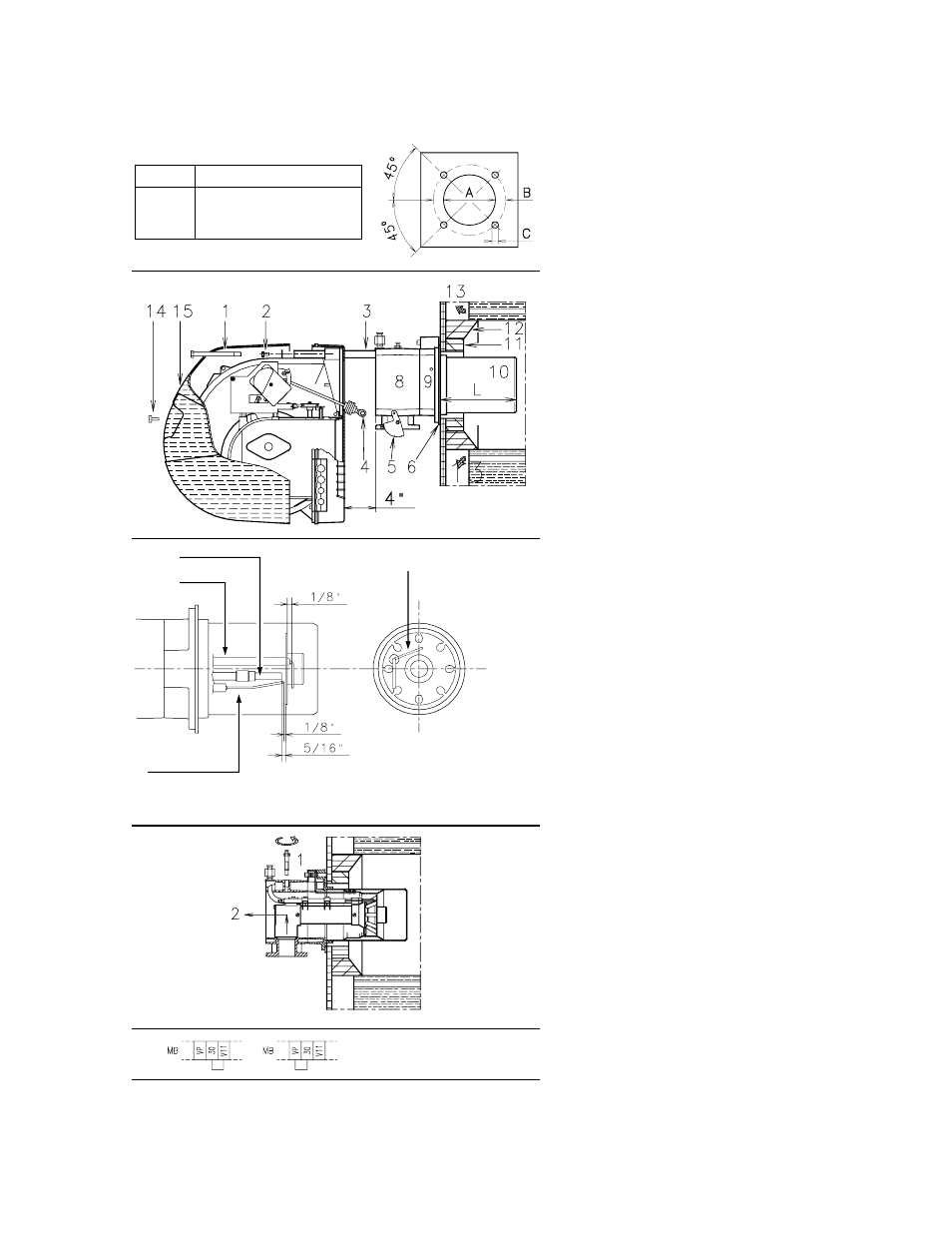

BURNER MOUNTING (A)

Drill the combustion chamber mounting plate as shown

in (A).

The position of the threaded holes can be marked using

the head gasket supplied with the burner.

BLAST TUBE LENGTH (B)

The length of the blast tube must be selected according

to the indications provided by the manufacturer of the

boiler, and it must be greater than the thickness of the

boiler door complete with its insulation. The range of

lengths available, L (inches), is as follows:

Blast tube 10): RS 28/M

RS 38/M

RS 50/M

• short

8

1/2

”

8

1/2

”

8

1/2

”

• long

13

13/16

”

13

13/16

”

13

13/16

”

For boilers with front flue passes 13) or flame inversion

chambers, protective insulation material 11) must be

inserted between the boiler refractory 12) and the blast

tube 10).

This protective insulation must not compromise the

extraction of the blast tube.

For boilers having a water-cooled front, the insulation

11)-12)(B) is not required unless it is required by the

boiler manufacturer.

SECURING THE BURNER TO THE BOILER (B)

Before securing the burner to the boiler, check through

the blast tube opening to make sure that the flame sen-

sor probe is correctly set in position, as shown in (C).

Now detach the combustion head from the burner,

fig.(B):

- Remove screw 14) and withdraw the cover 15).

- Disengage the swivel coupling 4) from the graduated

sector 5).

- Remove the screws 2) from the slide bars 3)

- Remove screw 1) and pull the burner back on slide

bars 3) by about 4”.

Disconnect the wires from the probe and the elec-

trode and then pull the burner completely off the slide

bars, after removing the split pin from the slide bar 3).

Secure the flange 9)(B) to the boiler plate, inserting the

head gasket 6)(B). Use the 4 screws, also supplied with

the unit, after first protecting the thread with an anti-seize

product.

The seal between burner and boiler must be airtight.

If you noticed any irregularities in the positions of the

probe or ignition electrode during the check mentioned

above, remove screw 1)(D), extract the internal part

2)(D) of the head and set up the two components cor-

rectly.

IGNITION PILOT ADJUSTMENT

Place the pilot and electrode as shown in fig. (C).

The pilot works correctly at pressures ranging from 5 -

12” WC.

Important

To set the pilot without main burner operation, proceed

as follows:

- Move the jumper from terminals "

30-V11" to terminals

"

30-VP", as given in fig. (E), this way the main valve is

not energized.

- With the burner in the manual position, hold the air

damper in the minimum position and make the setting.

- When the setting is correct, replace the jumper on “

30-

V11”.

(C)

inch

A

B

C

RS 28/M

6

9/32

“

8

13/16

“

3/8

W

RS 38/M

6

9/32

“

8

13/16

“

3/8

W

RS 50/M

6

9/32

“

8

13/16

“

3/8

W

D455

(A)

(D)

D2260

(B)

D2292

D2261

(E)

MB - Burner terminal strip

D2317

Probe

Electrode

Ignition pilot

TOP VIEW

SIDE VIEW

Probe position

123