Etanorm sya – B&C Technologies IM Series Industrial Ironer User Manual

Page 105

1215:6/2

F

V

F

H

F

H

F

H

F

H

F

V

+

+

1

2

2

2

L

Caution

Etanorm SYA

6

4.4

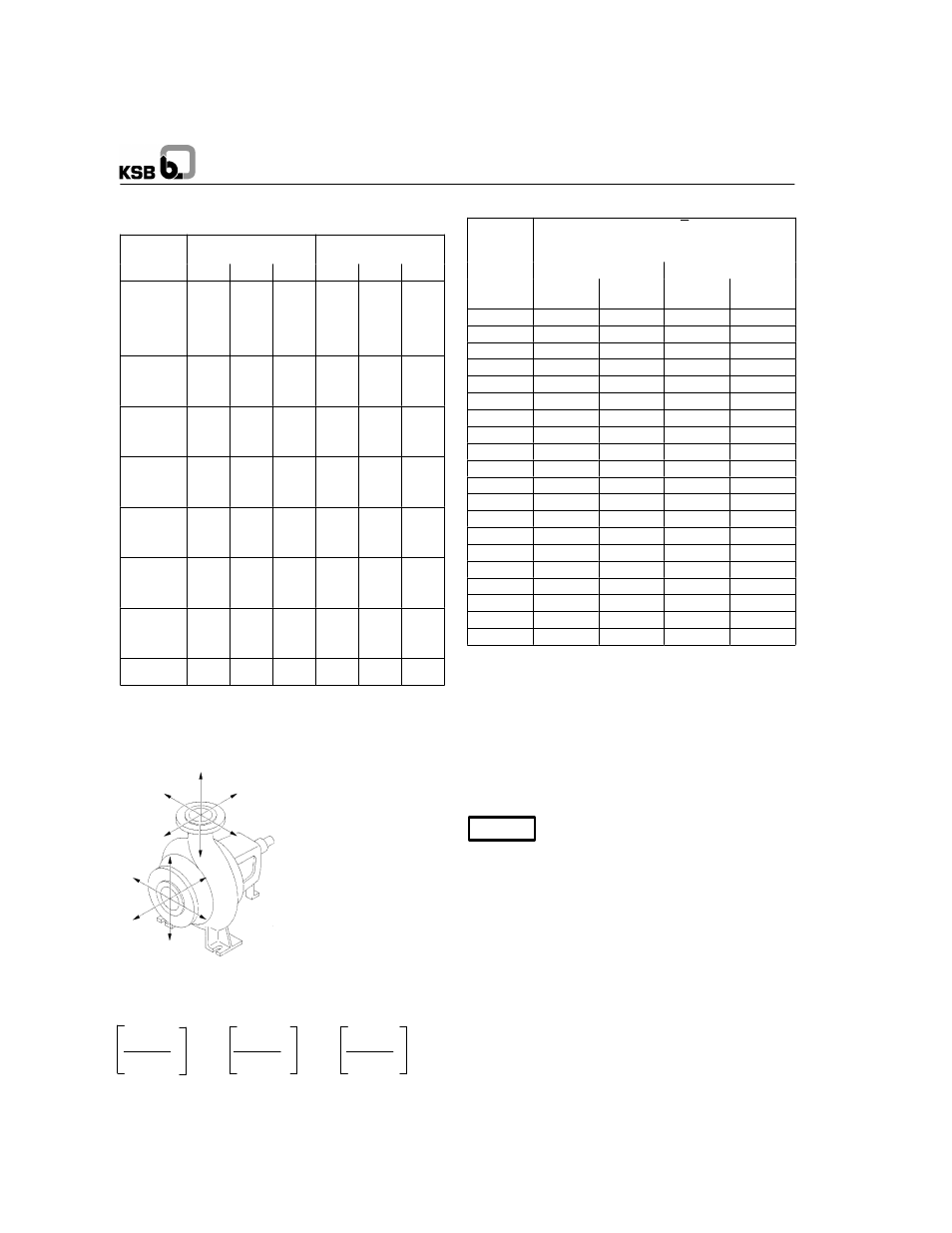

Permissible Forces and Moments at the Pump

Nozzles

Etanorm

SYA

t = 20

C

F

Vmax

F

Hmax

M

tmax

t = 300

C

F

Vmax

F

Hmax

M

tmax

[kN]

[kN]

[kNm]

[kN]

[kN]

[kNm]

32-125.1

32-160.1

32-200.1

32-160

32-200

32-250

3.65

3.56

3.60

3.56

3.65

3.65

2.59

2.51

2.43

2.51

2.43

2.43

0.58

0.51

0.51

0.51

0.51

0.51

3.15

3.08

3.11

3.08

3.11

3.11

2.24

2.17

2.10

2.17

2.10

2.10

0.50

0.44

0.44

0.44

0.44

0.44

40-160

40-200

40-250

40-315

3.81

3.81

4.21

4.09

2.67

2.67

2.92

2.84

0.81

0.81

0.58

0.55

3.29

3.29

3.64

3.54

2.31

2.31

2.52

2.46

0.70

0.70

0.50

0.48

50-160

50-200

50-250

50-315

3.97

4.21

4.58

4.54

2.67

2.92

3.32

3.24

1.11

1.11

0.87

0.84

3.43

3.64

3.96

3.92

2.31

2.52

2.87

2.80

0.96

0.96

0.75

0.73

65-160

65-200

65-250

65-315

4.42

5.27

5.27

5.43

3.04

3.89

3.89

4.05

1.16

1.79

1.79

1.62

3.82

4.55

4.55

4.69

2.63

3.36

3.36

3.50

1.00

1.55

1.55

1.40

80-160

80-200

80-250

80-315

5.43

6.08

6.16

6.28

4.05

4.74

4.78

4.86

1.91

2.44

2.44

2.78

4.69

5.25

5.32

5.43

3.50

4.10

4.13

4.20

1.65

2.10

2.10

2.40

100-160

100-200

100-250

100-315

7.70

7.70

7.86

7.57

6.28

6.28

6.48

6.16

3.60

3.60

3.47

3.18

6.65

6.65

6.79

6.54

5.43

5.43

5.60

5.32

3.10

3.10

3.00

2.75

125-200

125-250

125-315

125-400

9.50

9.84

9.32

9.23

8.50

8.71

8.10

7.90

5.10

5.10

4.75

4.63

8.21

8.50

8.05

7.97

7.34

7.53

7.00

6.83

4.40

4.40

4.10

4.00

150-315

150-400.1

10.53

10.53

9.72

9.72

5.67

5.67

9.10

9.10

8.40

8.40

4.90

4.90

The

values

indicated

apply

to pumps

made

of nodular

cast iron

JS 1025

3)

.

3) to EN 1563 = GJS-400-18-LT

Fig. 4.4-1 Forces and moments at the pump nozzles

The following condition must be met:

π

IF

V

I

π

IF

H

I

π

IM

t

I

IF

Vmax

I

IF

Hmax

I

IM

tmax

I

π

IF

V

I,

π

IF

H

I and

π

IM

t

I are the sums of the absolute values

of the respective loads acting on the nozzles. These sums

neither take into account the direction of the forces and mo-

ments nor their distribution among the nozzles.

4.5

Noise Characteristics

Rated

power

input P

N

Surface sound pressure level

pA

Pump only

Pump with motor

(kW)

1450 1/min

dB

1)

2900 1/min

dB

1)

1450 1/min

dB

2)

2900 1/min

dB

2)

0,55

46

48

50

56

0,75

48

50

52

58

1,1

50

52

55

60

1,5

51

53

56

62

2,2

53

55

58

64

3,0

55

57

60

66

4,0

57

59

62

67

5,5

58

60

63

69

7,5

60

62

65

70

11,0

62

64

66

72

15,0

63

66

68

74

18,5

64

67

69

75

22,0

65

68

70

75

30,0

67

69

71

77

37,0

68

71

72

77

45,0

69

72

73

78

55,0

70

73

73

79

75,0

72

74

75

80

90,0

73

75

75

80

110,0

74

76

76

81

1) Measured at a distance of 1 m from the pump outline

(to DIN 45 635 part 1 and 24)

2) Measured at a distance of 1 m from the complete unit outline

(to DIN 45 635, part 1 and 24)

The above noise characteristics apply to non-cavitating pump

operation in the Q

opt.

range.

4.6

Accessories

Drive

Surface cooled IEC three phase squirrel cage motor

When the pump is driven by an electric

motor, the motor’s cooling air must flow

in axial direction towards the pump end.

Air velocity

∫∫∫∫

3 m/s, measured at the

drive side bearing end plate. When the

pump is driven by an I.C. engine, only

such air-cooled engines shall be used

whose cooling air is drawn in and dis-

charged over the coupling/flywheel.

Coupling

Design:

Flexible coupling with or without spacer

Baseplate:

Channel section steel or folded steel plate

for the complete unit (pump and motor) in

torsion-resistant design

Drive, coupling and baseplate can be supplied by KSB or the

operator.

95