Etanorm sya, 3transport and interim storage, 4description of the product and accessories – B&C Technologies IM Series Industrial Ironer User Manual

Page 104

Caution

Etanorm SYA

5

Work on the machine must be carried out only during standstill.

The shutdown procedure described in the manual for taking the

machine out of service must be adhered to without fail.

Pumps or pump units handling media injurious to health must

be decontaminated.

Immediately following completion of the work, all safety-rele-

vant and protective devices must be re-installed and/or re-acti-

vated.

Please observe all instructions set out in the chapter on ”Com-

missioning” before returning the machine to service.

2.7 Unauthorized Modification and Manufacture of

Spare Parts

Modifications or alterations of the machine are only permitted

after consultation with the manufacturer. Original spare parts

and accessories authorized by the manufacturer ensure safety.

The use of other parts can invalidate any liability of the

manufacturer for consequential damage.

2.8 Unauthorized Modes of Operation

The warranty relating to the operational reliability and safety of

the pump / unit supplied is only valid if the machine is used in

accordance with its designated use as described in the follow-

ing sections of these operating instructions. The limits stated in

the data sheet must not be exceeded under any circumstances.

3

Transport and Interim Storage

3.1

Transport

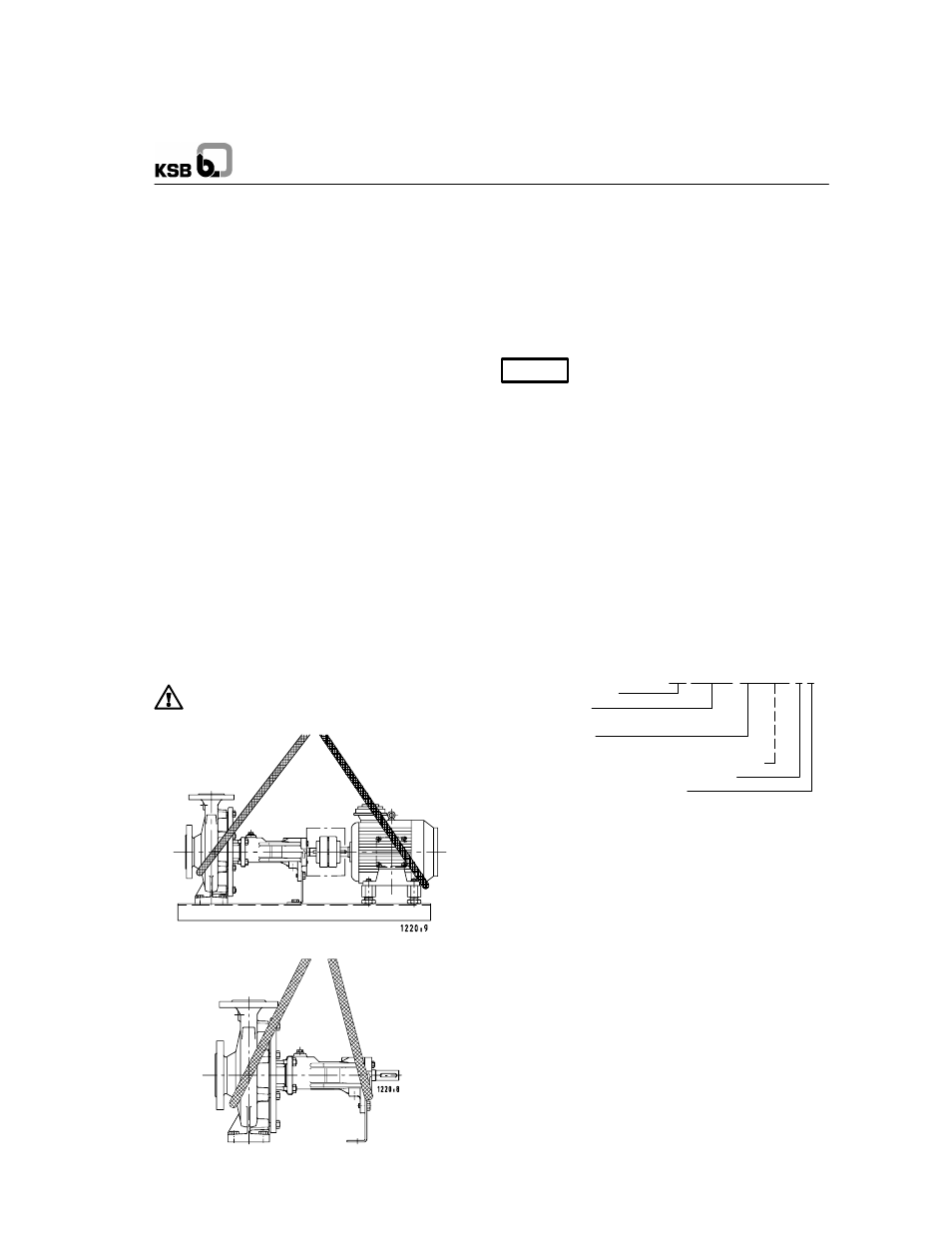

Transport of the unit requires proper preparation and handling.

Always make sure that the pump or the unit remains in horizon-

tal position during transport and cannot slip out of the transport

suspension arrangement. Do not use lifting slings on the free

shaft end of the pump or on the motor eyebolt.

If the pump / unit slips out of the suspension arrange-

ment, it may cause personal injury and damage to prop-

erty.

Fig. 3.1-1 Transport of the complete unit

Fig. 3.1-2 Transport of the pump

3.2

Interim Storage / Preservation

When the unit is temporarily put into storage, only the

wetted low alloy

components (e.g. nodular

cast

iron

JS1025

1)

, etc.) must be preserved. Commercially available

preservatives can be used for this purpose. Please observe the

manufacturer’s instructions for application/removal.

The unit / pump should be stored in a dry room where the atmo-

spheric humidity is as constant as possible.

If stored outdoors, the unit and crates must be covered by wa-

terproof material to avoid any contact with humidity.

Protect all stored goods against humidity, dirt,

vermin and unauthorized access!

All openings of the assembled unit components are closed and

must only be opened when required during installation.

All blank parts and surfaces of the pump are oiled or greased

(silicone-free oil and grease) to protect them against corrosion.

4

Description of the Product and

Accessories

4.1

Technical Specification

Volute casing pumps for heat transfer (DIN 4754) or hot water

circulation systems.

4.2

Designation

EN 80 - 160 66 (6239) S Y A

Type series Etanorm

Pump size, e.g.

Actual impeller diameter - 100 mm,

e.g. 166 mm =

(angular reduction of impeller vanes, e.g.

Etanorm 80-160 actual diameter 162/139 mm) =

Casing material nodular cast iron JS 1025

1)

Heat transfer oil/Hot water variant

1) to EN 1563 = GJS-400-18-LT

4.3

Design Details

Pump

Design:

horizontal volute casing pump, single-stage,

with ratings and main

dimensions to

EN 733, with bearing bracket in back pull-out

design. Volute casing with integrally cast

pump feet, with replaceable casing wear

rings.

Bearings:

coupling side:

grease-lubricated

deep-

groove ball bearing

impeller side:

product-lubricated carbon

bearing

Shaft seal:

mechanical seal

94