Step 3 — field fabricate ductwork, Step 4 — make unit duct connections, Step 5 — trap condensate drain – Carrier 50EY User Manual

Page 11: Table 2 — evaporator fan motor data

Table 2 — Evaporator Fan Motor Data

UNIT

SIZE

MOTOR

HP

MOTOR

SHAFT

DIAMETER

(in.)

FAN

SHAFT

SPEED

(rpm)

MOTOR

SHEAVE

MOTOR

SHEAVE

PITCH

DIAMETER

(in.)

BUSHING

DIAMETER

(in.)

FAN

SHEAVE

FAN

SHEAVE

PITCH

DIAMETER

(in.)

BUSHING

DIAMETER

(in.)

BELT

OUTSIDE

BELT

LENGTH

BELT

TENSION

(Lb @

.24 in.)

024

5

1.12

725

BK52

4.6

None-1.125

1B5V110

11.1

B-1.6875

BX59

62

5.02

10

1.38

924

BK72

6.6

None-1.375

1B5V124

12.5

B-1.6875

BX60

63

7.05

15

1.62

1088

1B5V68

6.9

B-1.625

1B5V110

11.1

B-1.6875

5VX590

59

9.38

028

7.5

1.38

773

BK55H

4.9

H-1.375

1B5V110

11.1

B-1.6875

BX56

59

6.87

10

1.38

962

BK67H

6.1

H-1.375

1B5V110

11.1

B-1.6875

BX56

59

7.26

15

1.62

1119

1B5V70

7.1

B-1.625

1B5V110

11.1

B-1.6875

5VX590

59

9.17

030

10

1.38

843

BK72

6.6

None-1.375

1B5V136

13.7

B-1.6875

BX62

65

6.96

15

1.62

1056

1B5V66

6.7

B-1.625

1B5V110

11.1

B-1.6875

5VX590

59

9.60

20

1.62

1182

1B5V74

7.5

B-1.625

1B5V110

11.1

B-1.6875

5VX600

60

11.67

034

10

1.38

896

BK70H

6.4

H-1.375

1B5V124

12.5

B-1.6875

BX60

63

7.20

15

1.62

1088

1B5V68

6.9

B-1.625

1B5V110

11.1

B-1.6875

5VX590

59

9.38

20

1.62

1182

1B5V74

7.5

B-1.625

1B5V110

11.1

B-1.6875

5VX600

60

11.17

038

10

1.38

788

2BK47

4.1

None-1.375

2B5V90

9.1

B-1.6875

BX51

54

5.49

15

1.62

966

1B5V68

6.9

B-1.625

1B5V124

12.5

B-1.6875

5VX630

63

9.22

20

1.62

1050

1B5V74

7.5

B-1.625

1B5V124

12.5

B-1.6875

5VX650

65

10.02

044

15

1.62

966

1B5V68

6.9

B-1.625

1B5V124

12.5

B-1.6875

5VX630

63

9.54

20

1.62

1035

1B5V80

8.1

B-1.625

1B5V136

13.7

B-1.6875

5VX670

67

10.37

25

1.88

1162

1B5V90

9.1

B-1.875

1B5V136

13.7

B-1.6875

5VX680

68

10.88

048

20

1.62

1019

2B5V52

5.3

B-1.625

2B5V90

9.1

B-1.6875

5VX550

55

7.93

25

1.88

1135

2B5V58

5.9

B-1.875

2B5V90

9.1

B-1.6875

5VX560

56

8.66

30

1.88

1182

2B5V76

7.5

B-1.875

2B5V110

11.1

B-1.6875

5VX610

59

9.07

NOTE: Motor shaft speed is 1750 rpm. The fan shaft diameter is 1

11

⁄

16

inches.

ROOF MOUNT — Check building codes for weight distri-

bution requirements.

Step 3 — Field Fabricate Ductwork —

Secure all

ducts to building structure. Use flexible duct connectors be-

tween unit and ducts as required. Insulate and weatherproof

all external ductwork, joints, and roof openings with counter

flashing and mastic in accordance with applicable codes.

Ducts passing through an unconditioned space must be

insulated and covered with a vapor barrier.

To attach ductwork to roof curb, insert ductwork approxi-

mately 10 to 11 in. up into the curb. Connect ductwork to

14-gage roof curb material using sheet metal screw driven

from inside the duct.

The units with electric heat require a 1-in. clearance for

the first 24 in. of ductwork.

NOTE: A 90-degree elbow must be provided in the duct-

work to comply with UL (Underwriters’ Laboratories) codes

for use with electric heat.

Outlet grilles must not lie directly below unit discharge.

Step 4 — Make Unit Duct Connections

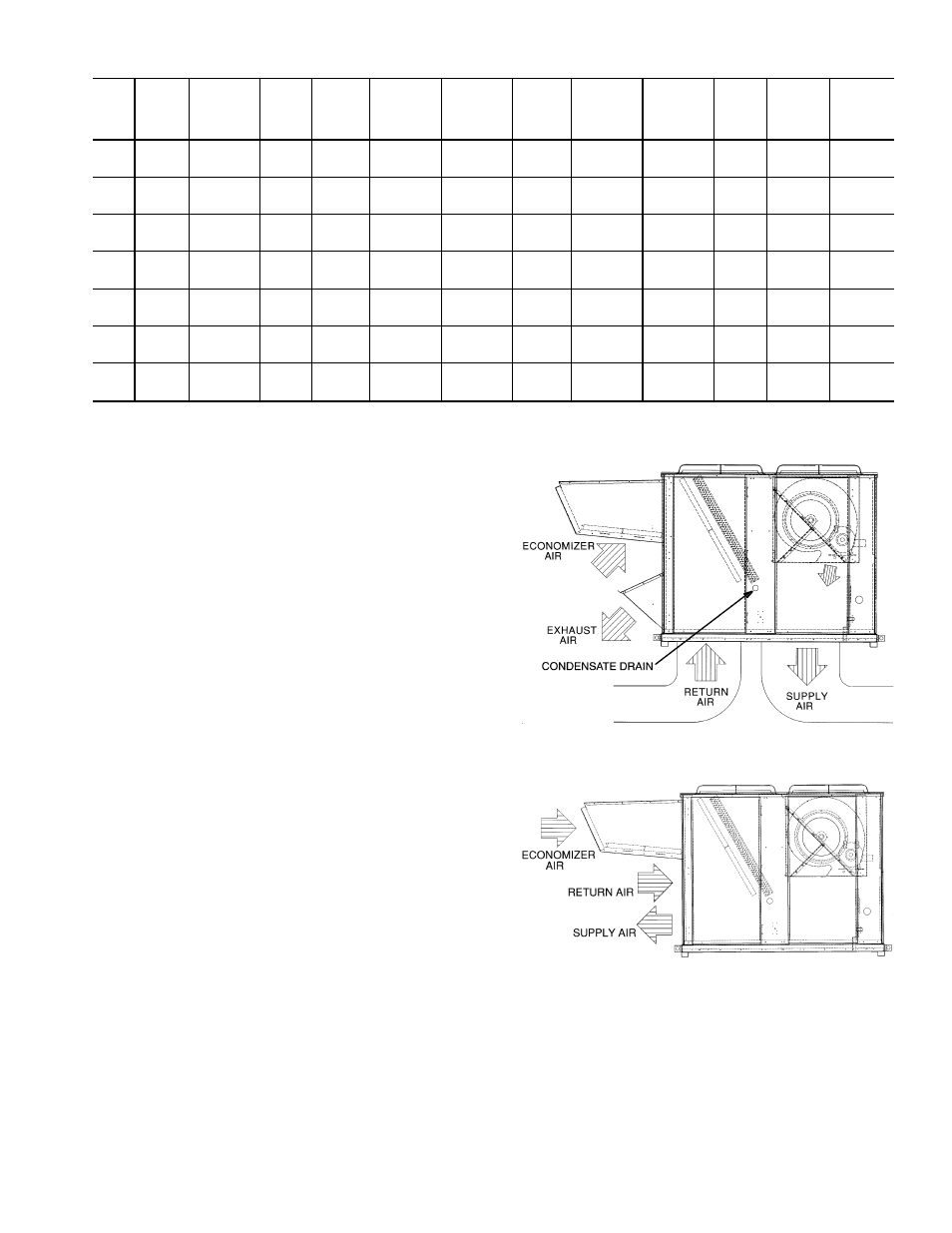

50EJ,EK UNITS — Unit is shipped for through-the-bottom

duct connections. Ductwork openings are shown in Fig. 3

and 4. Attach all ductwork to roof curb. Air distribution

is shown in Fig. 8. Refer to installation instructions shipped

with accessory roof curb for more information.

50EW,EY UNITS — Remove shipping covers from supply

and return air openings. Attach field-supplied ductwork to

unit. Use a single duct over both return openings and a single

duct over both supply openings. See Fig. 5 and 6 for duct

opening dimensions. Secure all ducts to the building struc-

ture. See Fig. 9. Use flexible duct connectors between unit

and ducts as required.

Install accessory barometric relief or power exhaust in the

field-fabricated return ductwork. Refer to Position Power

Exhaust/Barometric Relief Damper Hood Section on

page 29 for more information.

Step 5 — Trap Condensate Drain —

See Fig. 3-6

and 10 for drain location. Condensate drain is open to the

atmosphere and must be trapped. Install a trapped drain at

the drain location. One 1-in. FPT coupling is provided in-

side unit evaporator section for condensate drain connec-

tion. A trap at least 4-in. deep must be used. Trap must be

installed to prevent freeze-up.

Condensate pans are sloped so that water will completely

drain from the condensate pan to comply with indoor air qual-

ity guidelines.

Fig. 8 — Air Distribution — Thru-the-Bottom

Fig. 9 — Air Distribution — Thru-the-Side

11