Vintage Cellars Split System CellarPro User Manual

Page 32

32

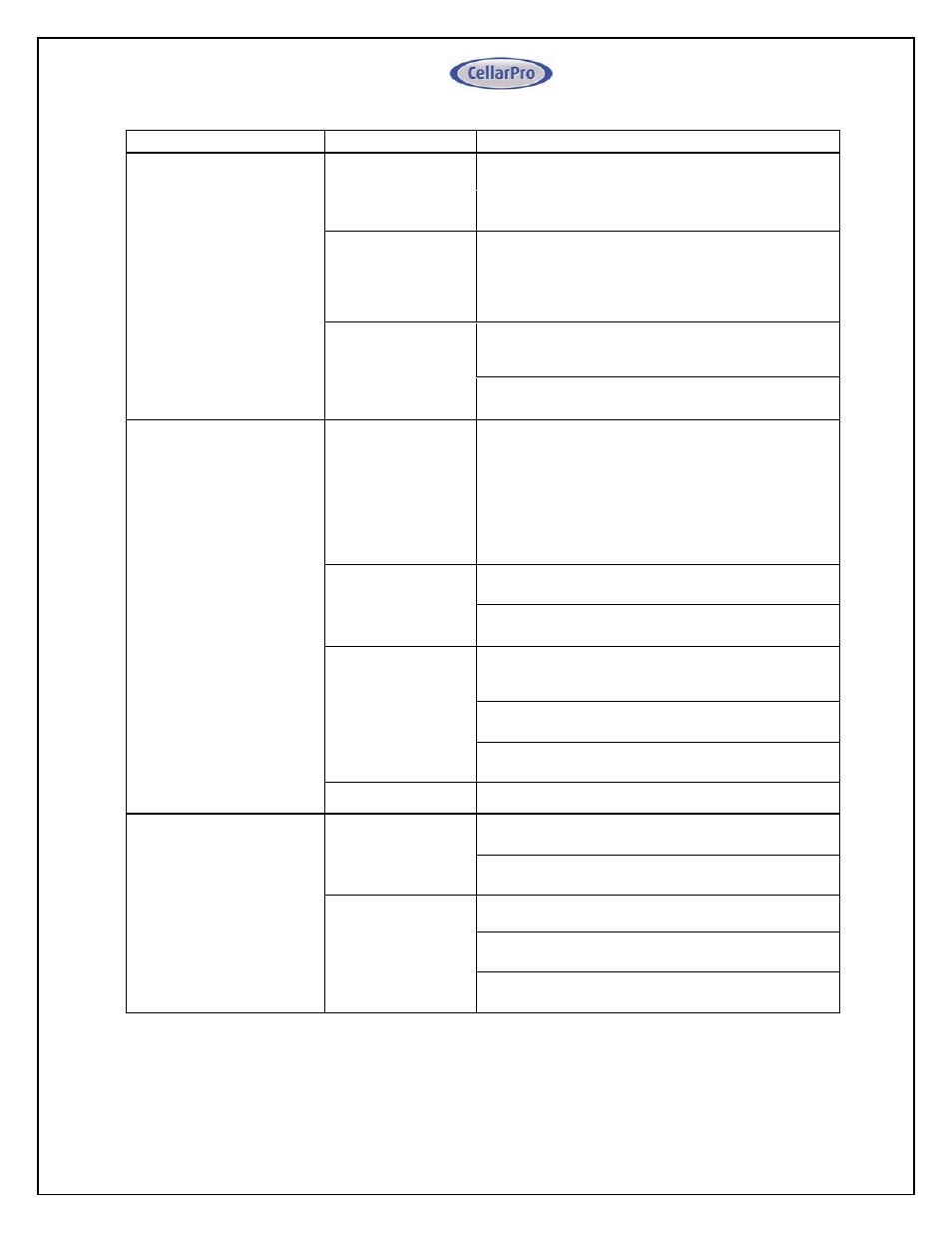

Issue

Possible Causes

Potential Solutions

No cooling: Evaporator

fan not blowing.

If the "fan" icon is

illuminated on the

temperature display

control, the fan should be

blowing air.

No power to fan

Power supply to Evaporator interrupted. Restore

power.

Power supply to fan interrupted: loose wire.

Inspect for loose fan wiring and reconnect.

Fan obstructed

With power to unit disconnected, check the

rotation of the blower fan. If fan does not spin

freely, inspect for and remove obstructions. If no

obstructions are found, the fan may need to be

replaced. Consult factory.

Fan running but

not drawing air

through coil.

Fan short cycling: Make sure all housing panels

are attached to the unit. Replace missing panels.

Coil is blocked with ice. Refer to the "Iced coil"

section.

Iced coil

Insufficient number

of defrosts

Turn system off and melt ice from coil. Decrease

the defrost interval from the default value of 16

hours by changing second level parameter "idF"

to a minimum setting of 4 hours. If this corrects

the problem, optimize the defrost frequency by

setting and observing the system at different set

points above “4” and below “16” to ensure the

system is configured for maximum run time.

Low refrigerant

charge

System charged incorrectly. Review process and

correct.

Leak in system. Find and repair leak, recharge

system.

Mal-functioning

thermostatic

expansion valve.

Incorrect superheat setting: determine superheat

and adjust. If expansion valve is faulty, replace.

Expansion valve bulb not located correctly -

review installation instructions and correct.

Liquid flashing at the expansion valve inlet. See

"High liquid line pressure drop" section.

No airflow

See "Evaporator fan not blowing" section

Insufficient liquid sub-

cooling

Low refrigerant

charge

System charged incorrectly. Review process and

correct.

Leak in system. Find and repair leak, recharge

system.

High liquid line

pressure drop

Check for plugged filter drier and replace if

necessary.

Inspect pipe routing for proper piping practices

and correct.

Liquid line picking up too much ambient heat -

may need to insulate.