Vintage Cellars Split System CellarPro User Manual

Page 31

31

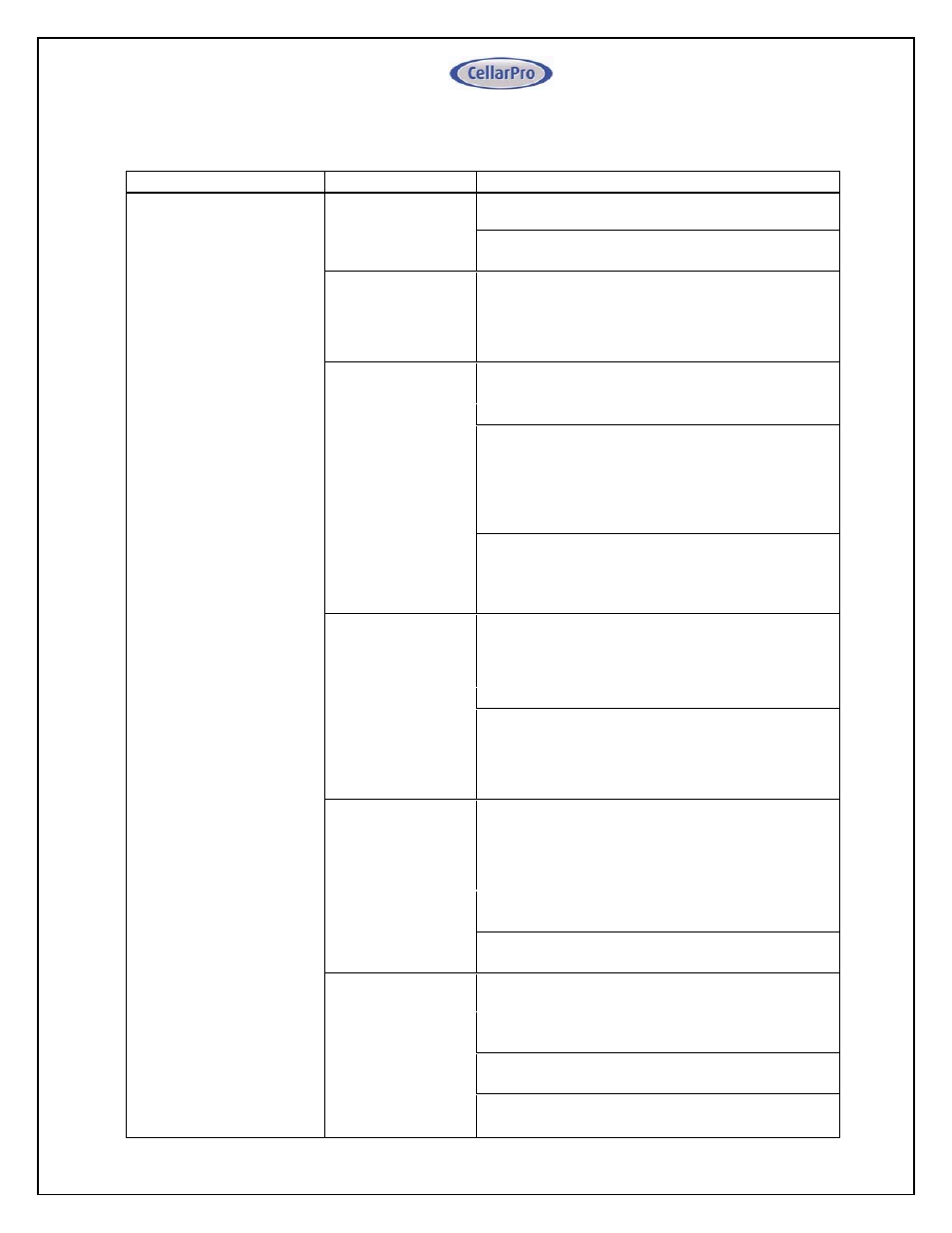

Other Troubleshooting Issues

Issue

Possible Causes

Potential Solutions

No cooling: no refrigerant

flow.

If the "snowflake" icon is

illuminated on the

temperature display

control, the liquid line

solenoid should be

energized and the

compressor running.

No power to liquid

solenoid valve coil

Power supply to Evaporator interrupted. Restore

power.

Power supply to solenoid coil interrupted: loose

wire. Inspect for loose fan wiring and reconnect.

Solenoid coil

failure

When the Evaporator is powered on and off, a

distinct "click" should be heard indicating the

opening/closing of the solenoid valve. If not, the

solenoid coil may need to be replaced. Consult

factory.

No power to

compressor

Power supply to Condensing Unit interrupted.

Restore power.

Check for loose wires and reconnect.

Low pressure switch is open: make sure solenoid

is energized and condensing unit service valves

are open. Jumper out switch to check for a faulty

switch, and replace if necessary. Note that in

installations below 0°F this switch may remain

open. Consult factory.

High pressure switch is open: make sure

condensing unit service valves are open. If this

does not correct the problem, refer to the "High

Pressure Safety Shutdown" section.

High pressure

safety shutdown /

high discharge

pressure

Locate and correct source of high condensing

head pressure:

Refrigeration line blockage

Condenser fan not operating in ambient

temperatures above 90°F. Ensure that there is

power to the Condensing Unit and verify the fan

cycling control settings. Replace condenser fan

and fan cycling control if necessary.

(Cont.) High

pressure safety

shutdown / high

discharge

pressure

Insufficient ventilation: reference Condensing

Unit installation guidelines for proper placement

and ambient temperature requirements. Correct

to ensure adequate air ventilation to and from the

Condensing Unit.

Improper refrigerant charge: inspect for over-

charged system or non-condensibles in system.

Dirty or obstructed condenser coil: clean and

remove all obstructions to airflow.

Intermittent power

to compressor

Check for loose wires and secure.

Compressor cycling on internal thermal overload

protection. Replace start capacitor/relay assembl

Compressor cycling on high pressure - see "High

pressure safety shutdown" section.

Faulty compressor. Consult factory.