Diagram b diagram c – Tjernlund CPC-3 Constant Pressure Controller Startup Manual 8504125 User Manual

Page 4

SUGGESTED COMPONENT PHYSICAL PLACEMENT

Although it is not necessary to install the CPC-3 and related VFD(s) adjacent to each other it is highly recommended since both dis-

plays may need to be viewed simultaneously during system startup or servicing. A faulted VFD can be reset from either the CPC-3 or

the VFD.

MAXIMUM LEAD LENGTH FROM CPC-3 CONTROLLER:

Transducer: 150 feet with 18 AWG (3 leads required)

Manual Mode PSA-1 Proving Switch: 325 feet with 18 AWG (2 leads required)

VFD Control Signal: 220 feet with 18 AWG (10 leads required)*

*VFD comes with 10 foot set of leads terminated with a VFD quick connect

MAXIMUM LEAD LENGTH FROM VFD TO INDUCER/BLOWER:

230 VAC Models: 300 feet with 14 AWG, 600 VAC Insulation

460 VAC Models: 100 feet with 14 AWG, 600 VAC insulation

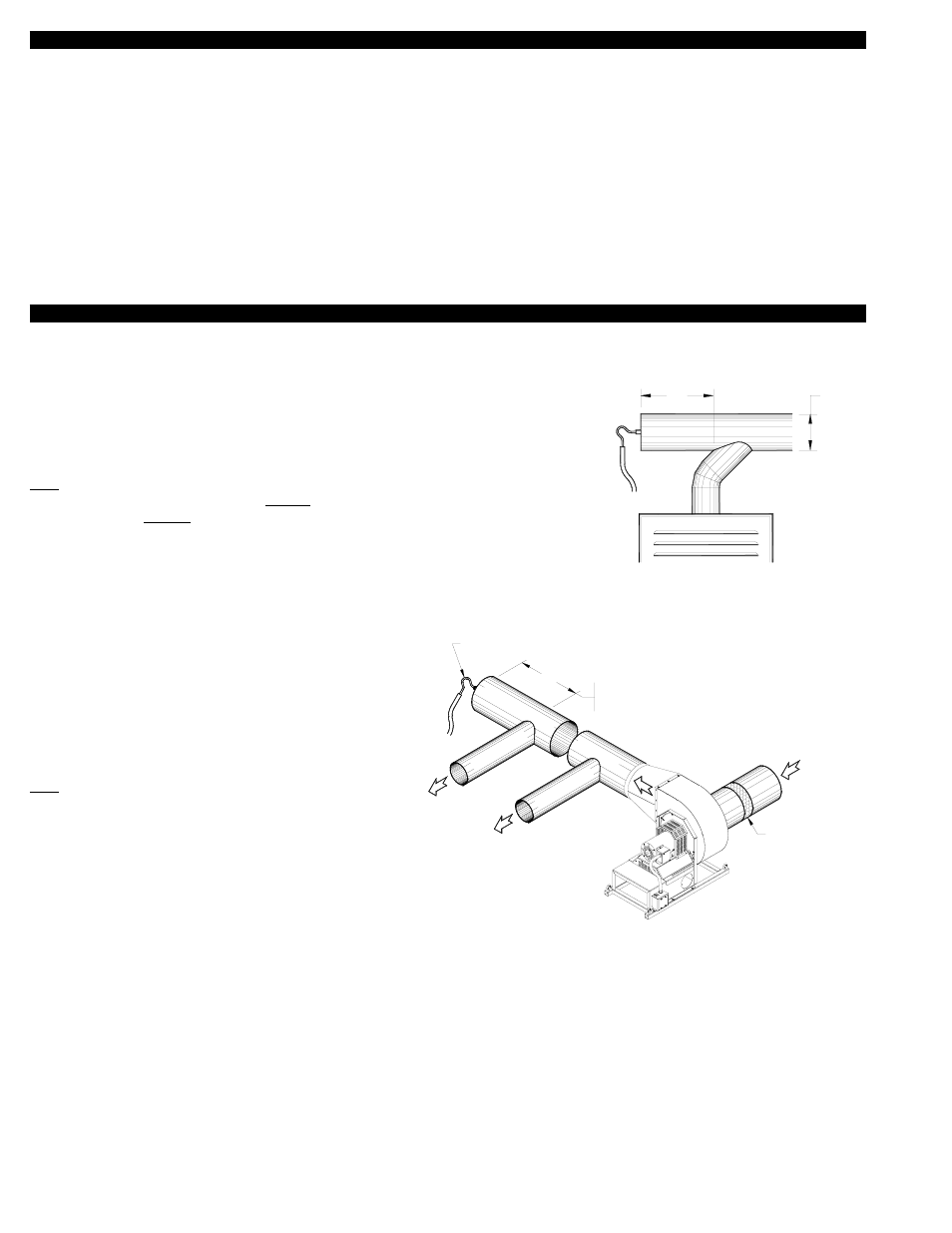

TRANSDUCER SENSING TUBE INSTALLATION

FOR MECHANICAL DRAFT INSTALLATIONS

The TD-2 Transducer sensing tube should be installed in

the cap of a tee or rear of a common manifold. The tee is

necessary so that only static pressure is measured. If the

transducer sensing tube is installed in the side of a vent

pipe it will also measure velocity pressure, giving an incor-

rect signal back to the CPC-3 Controller. If mounting on the

side of the pipe is unavoidable, the sensing tube should be

flush to the interior wall of the vent pipe. Typically, draft

applications should sample at a point in back of the vent

connection that is farthest from the inducer/blower, See

Diagram B.

FOR “SEALED” COMBUSTION AIR APPLICATIONS

The TD-2 Transducer sensing tube should be installed in

the capped end of a common supply manifold. This is nec-

essary so that only static pressure is measured. If the

transducer sensing tube is installed in the side of a duct it

will also measure velocity pressure, giving an incorrect sig-

nal back to the CPC-3 Controller. If mounting on the side of

the duct pipe is unavoidable, the sensing tube should be

flush to the interior wall of the duct. If a filter is installed it

must be positioned between the blower inlet and intake

opening, See Diagram C.

FOR “OPEN” COMBUSTION AIR APPLICATIONS

In "Open" mode the mechanical room air is sampled and an adjacent space is referenced. Referencing an adjacent space within the

building typically provides a more stable reference pressure than referencing outdoor air. In both cases, the goal is to reference static

pressure. Don't sample pressures at locations that can be affected by frequently opened doors, elevator shafts, ventilation fans and

diffusers. The model IPS-1 includes a decorative cover, sampling tube and fittings and when used in conjunction with the TD-3

Transducer may be used to sample indoor reference pressure. It reduces the effects of air movement on the sampling tube and pro-

vides a finished look. Varying wind speeds will affect outdoor reference pressure and are difficult to neutralize. If sampling outdoor ref-

erence pressure, the model WW-1 may be used in conjunction with the TD-3 Transducer to help neutralize the effects of winds. For

best performance mount the WW-1 at least one foot away from an outside wall

3

D

2D

FROM VENTER

HEATER FURTHEST

8054004 12/8/04

BACK FROM THE MANIFOLD.

BE 2 TIMES THE DIAMETER OF THE PIPE

IF POSSIBLE, THE SENSING TUBE SHOULD

BACK FROM THE LAST HEATER MANIFOLD.

BE 2 TIMES THE DIAMETER OF THE PIPE

IF POSSIBLE, THE SENSING TUBE SHOULD

2D

FIGURE 8054005 12/9/04

LAST

HEAT

ER

FIRST

HEAT

ER

COM

BUSTION AIR

MA

NIFO

LD

COMBUSTION

AIR INTAKE

INSTALLER-SUPPLIED

FILTRATION MUST BE ON

BLOWER INLET SIDE.

SENSING TUBE

DIAGRAM B

DIAGRAM C