21 table 13 — troubleshooting – Carrier AQUAZONE 50PSW036-360 User Manual

Page 21

21

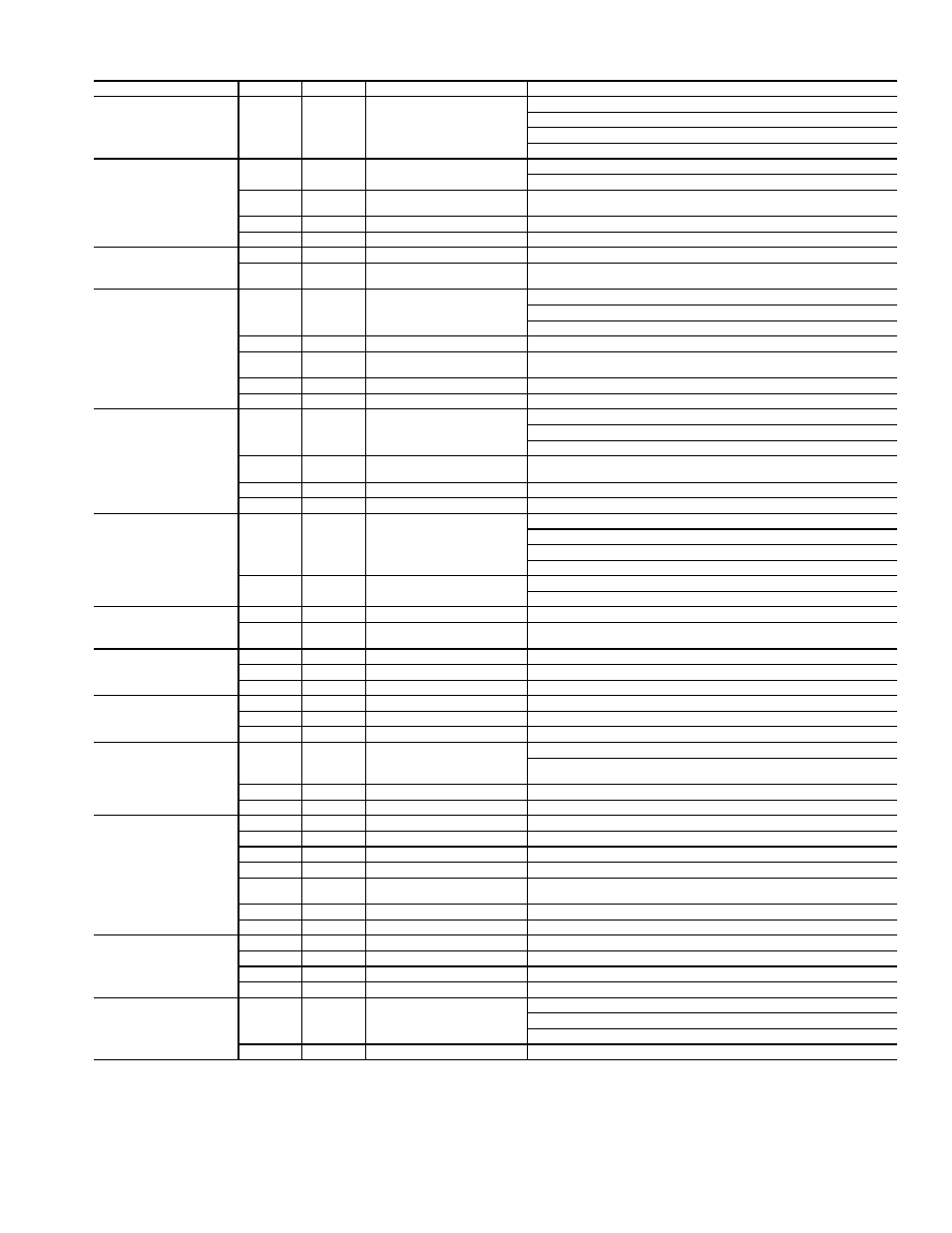

Table 13 — Troubleshooting

LEGEND

FAULT

HEATING

COOLING

POSSIBLE CAUSE

SOLUTION

Main Power Problems

X

X

Green Status LED Off

Check line voltage circuit breaker and disconnect.

Check for line voltage between L1 and L2 on the contactor.

Check for 24-vac between R and C on controller.

Check primary/secondary voltage on transformer.

HP Fault — Code 2

High Pressure

X

Reduced or no water flow in

cooling

Check pump operation or valve operation/setting.

Check water flow adjust to proper flow rate.

X

Water temperature out of range

in cooling

Bring water temperature within design parameters.

X

X

Overcharged with refrigerant

Check superheat/subcooling vs. typical operating condition.

X

X

Bad HP switch

Check switch continuity and operation. Replace.

LP/LOC Fault — Code 3

Low Pressure/Loss of

Charge

X

X

Insufficient charge

Check for refrigerant leaks.

X

Compressor pump down at

start-up

Check charge and start-up water flow.

FP1 Fault — Code 4

Source Water Freeze

Protection

X

Reduced or no water flow in

heating

Check pump operation or water valve operation/setting.

Plugged strainer or filter. Clean or replace.

Check water flow adjust to proper flow rate.

X

Inadequate antifreeze level

Check antifreeze density with hydrometer.

X

Improper freeze protect setting

(–1.1 C vs –12.2 C)

Clip JW3 jumper for antifreeze (–12.2 C) use.

X

Water temperature out of range

Bring water temperature within design parameters.

X

X

Bad thermistor

Check temperature and impedance correlation.

FP2 Fault — Code 5

Load Coil Freeze

Protection

X

Reduced or no water flow in

heating

Check pump operation or water valve operation/setting.

Plugged strainer or filter. Clean or replace.

Check water flow adjust to proper flow rate.

X

Improper freeze protect setting

(–1.1 C vs –12.2 C)

Clip JW3 jumper for antifreeze (–12.2 C) use.

X

Water temperature out of range

Bring water temperature within design parameters.

X

X

Bad thermistor

Check temperature and impedance correlation.

Over/Under Voltage —

Code 7

(Auto Resetting)

X

X

Under voltage

Check power supply and 24-vac voltage before and during operation.

Check power supply wire size.

Check compressor starting.

Check 24-vac and unit transformer tap for correct power supply voltage.

X

X

Over voltage

Check power supply voltage and 24-vac before and during operation.

Check 24-vac and unit transformer tap for correct power supply voltage.

Performance Monitor —

Code 8

X

Heating mode FP2>51.7 C

Check for overcharged unit.

X

Cooling mode FP1>51.7 C OR

FP2< 4.4 C

Check for poor water flow or airflow.

No Fault Code Shown

X

X

No compressor operation

See scroll compressor rotation section.

X

X

Compressor overload

Check and replace if necessary.

X

X

Control board

Reset power and check operation.

Unit Short Cycles

X

X

Unit in Test mode

Reset power or wait 20 minutes for auto exit.

X

X

Unit selection

Unit may be oversized for space. Check sizing for actual load of space.

X

X

Compressor overload

Check and replace if necessary.

Unit Does Not Operate in

Cooling

X

Reversing valve

Set for cooling demand and check 24-vac on RV coil and at control.

If RV is stuck, run high pressure up by reducing water flow and while operat-

ing engage and disengage RV coil voltage to push valve.

X

Thermostat setup

Check for ‘O’ RV setup not ‘B’.

X

Thermostat wiring

Check O wiring at heat pump. Jumper O and R for RV coil.

Insufficient Capacity/

Not Cooling or Heating

Properly

X

X

Low refrigerant charge

Check superheat and subcooling.

X

X

Restricted metering device

Check superheat and subcooling. Replace.

X

Defective reversing valve

Perform RV touch test.

X

X

Thermostat improperly located

Check location and for air drafts behind thermostat.

X

X

Unit undersized

Recheck loads and sizing. Check sensible cooling load and heat pump

capacity.

X

X

Scaling in water heat exchanger Perform scaling check and clean if necessary.

X

X

Inlet water too hot or cold

Check load, loop sizing, loop backfill, ground moisture.

High Head Pressure

X

Scaling in water heat exchanger Perform scaling check and clean if necessary.

X

X

Unit overcharged

Check superheat and subcooling. Reweigh in charge.

X

X

Non-condensables in system

Vacuum system and reweigh in charge.

X

X

Restricted metering device

Check superheat and subcooling. Replace.

Low Suction Pressure

X

Reduced water flow in heating

Check pump operation or water valve operation/setting.

Plugged strainer or filter. Clean or replace.

Check water flow adjust to proper flow rate.

X

Water temperature out of range

Bring water temperature within design parameters.

FP

— Freeze Protection

HP

— High Pressure

LED — Light-Emitting Diode

LOC — Loss of Charge

LP

— Low Pressure

RV

— Reversing Valve