Start-up, Operating limits (see table 6), Unit start-up – Carrier AQUAZONE 50PSW036-360 User Manual

Page 14: Scroll compressor rotation, Flow regulation, Warning, Caution

14

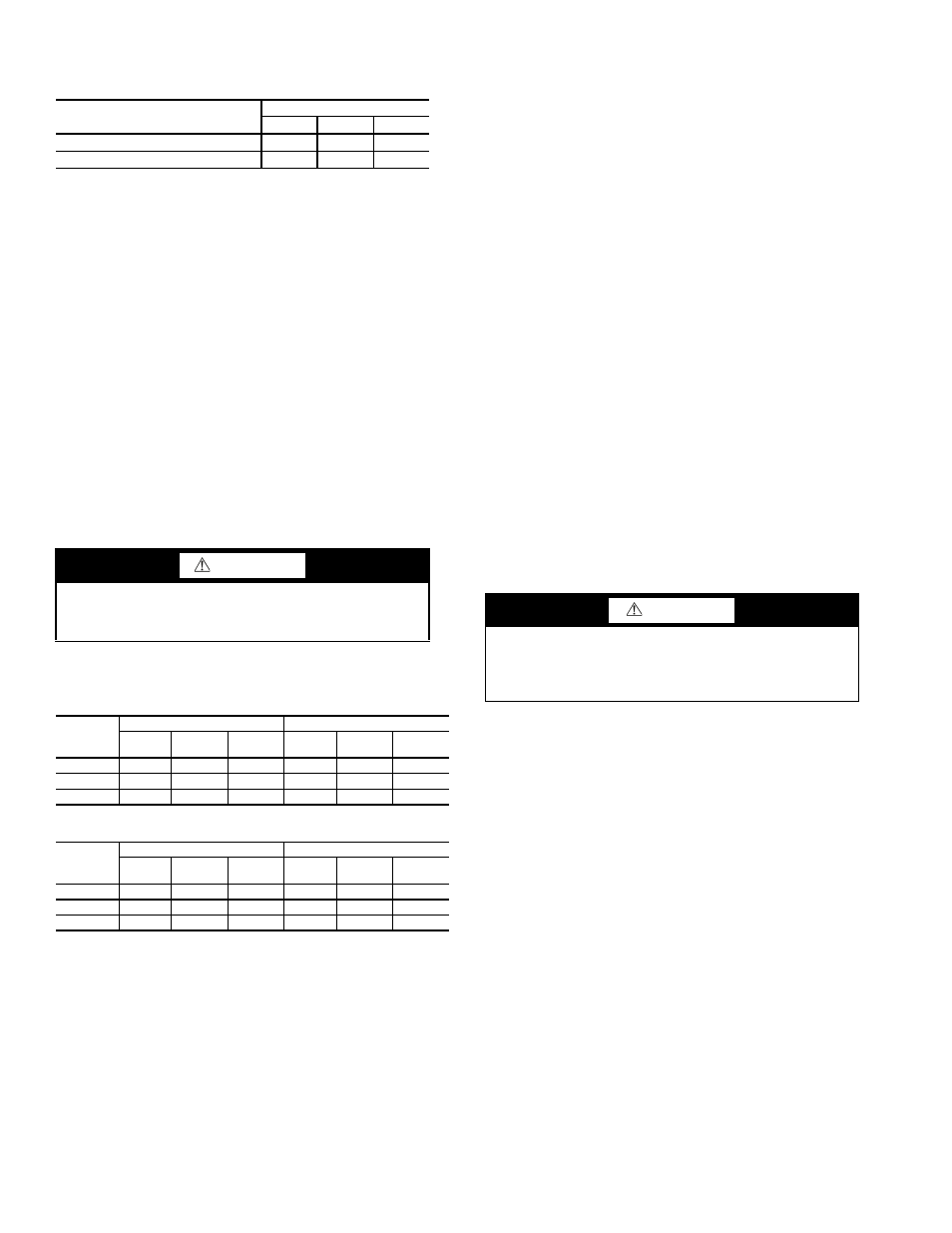

Table 5 — DIP Switch Block S2 —

Accessory 2 Relay Options

LEGEND

NOTE: All other DIP switch combinations are invalid.

START-UP

Use the procedure outlined below to initiate proper unit

start-up.

NOTE: This equipment is designed for indoor installation

only.

Operating Limits (See Table 6)

ENVIRONMENT — This equipment is designed for indoor

installation ONLY. Extreme variations in temperature, humidi-

ty and corrosive water or air will adversely affect the unit per-

formance, reliability and service life.

POWER SUPPLY — A voltage variation of ± 10% of name-

plate utilization voltage is acceptable.

NOTE: These operating conditions are not normal or continu-

ous operating conditions. It is assumed that start-up is for the

purpose of bringing the building space up to occupancy

temperature.

Table 6 — 50PSW Unit Operating Limits (C)

BUILDING COMMISSIONING

BUILDING OPERATING

Unit Start-Up

1. Turn off all power to unit.

2. Adjust all valves to full open position.

3. Restore power to unit.

4. Operate each unit in the cooling cycle. See Table 6 for

unit entering water temperatures.

5. Operate each heat pump in the heating cycle immediately

after checking cooling cycle operation.

NOTE: A time delay will prevent the compressor from

re-starting for approximately 5 minutes. The time delay

function can be overridden on the Complete C control

board.

6. If unit fails to operate, perform the following system

checks:

a. Check the voltage and current. Be sure they com-

ply with electrical data on unit nameplate.

b. Check for loose terminal screws where wire con-

nections have been made on both the line and low-

voltage terminal boards.

c. Check the supply and return piping. Be sure they

are properly connected to the inlet and outlet con-

nections on the unit.

d. If the checks described above fail to reveal the

problem and the unit still will not operate, contact

a trained service technician to ensure proper

diagnosis.

Scroll Compressor Rotation —

It is important to be

certain compressor is rotating in the proper direction. To

determine whether or not compressor is rotating in the proper

direction:

1. Connect service gages to suction and discharge pressure

fittings.

2. Energize the compressor.

3. The suction pressure should drop and the discharge

pressure should rise, as is normal on any start-up.

If the suction pressure does not drop and the discharge

pressure does not rise to normal levels:

1. Turn off power to the unit. Install disconnect tag.

2. Reverse any two of the unit power leads.

3. Reapply power to the unit and verify pressures are cor-

rect. The suction and discharge pressure levels should

now move to their normal start-up levels.

After a few minutes of reverse operation, the scroll com-

pressor internal overload protection will open, thus activating

the unit lockout. This requires a manual reset. To reset, turn the

thermostat on and then off.

NOTE: There is a 5-minute time delay before the compressor

will start.

Flow Regulation —

Flow regulation can be accom-

plished by two methods. Most water control valves have a flow

adjustment built into the valve. By measuring the pressure drop

through the unit heat exchanger, the flow rate can be deter-

mined. Adjust the water control valve until the flow of 0.09 to

0.13 L/s is achieved. Since the pressure constantly varies, two

pressure gages may be needed in some applications. See

Table 7 for heat exchanger pressure drops.

An alternative method is to install a flow control device.

These devices are typically an orifice of plastic material de-

signed to allow a specified flow rate that are mounted on the

outlet of the water control valve. Occasionally these valves

produce a velocity noise that can be reduced by applying some

back pressure. To accomplish this, slightly close the leaving

isolation valve of the water regulating device.

ACCESSORY 2

RELAY OPTIONS

DIP SWITCH POSITION

4

5

6

Digital NSB

Off

On

On

Water Valve — Slow Opening

On

Off

On

NSB — Night Setback

WARNING

When the disconnect switch is closed, high voltage is pres-

ent in some areas of the electrical panel. Exercise caution

when working with the energized equipment.

50PSW

UNIT SIZE

COOLING

HEATING

Source

Min/Max

Load

Min/Max

Ambient

Min/Max

Source

Min/Max

Load

Min/Max

Ambient

Min/Max

036

10/43

16/27

7/43

–1/27

16/49

4/29

060,120

10/49

16/32

7/43

–1/27

16/49

4/29

180,360

10/32

16/32

7/43

10/21

27/49

4/29

50PSW

UNIT SIZE

COOLING

HEATING

Source

Min/Max

Load

Min/Max

Ambient

Min/Max

Source

Min/Max

Load

Min/Max

Ambient

Min/Max

036

10/49

10/32

7/43

–7/27

16/54

4/29

060,120

10/49

10/32

7/43

–7/27

16/54

4/29

180,360

10/43

10/32

7/43

–7/21

16/49

4/29

CAUTION

When the compressor is rotating in the wrong direction, the

unit makes an elevated level of noise and does not provide

cooling. Damage to compressor will occur if allowed to

operate in this manner.