General, Installation step 1 — check jobsite, Step 2 — check unit – Carrier AQUAZONE 50PSW036-360 User Manual

Page 2: Warning, Caution

2

Recognize safety information. This is the safety alert

symbol (

). When you see this symbol on the unit and in

instructions or manuals, be alert to the potential for personal

injury.

GENERAL

The Aquazone™ 50PSW water source heat pump (WSHP)

is a single-package vertically mounted unit with electronic con-

trols designed for year-round cooling and heating.

INSTALLATION

Step 1 — Check Jobsite —

Installation, operation and

maintenance instructions are provided with each unit. Before

unit start-up, read all manuals and become familiar with the

unit and its operation. Thoroughly check out the system before

operation. Complete the inspections and instructions listed

below to prepare a unit for installation. See Table 1 for unit

physical data.

Units are designed for indoor installation only. Be sure to al-

low adequate space around the unit for servicing. See Fig. 1

and 2 for overall unit dimensions.

These units are not approved for outdoor installation and

must be installed indoors in the structure being conditioned. Do

not locate in areas where ambient conditions are not main-

tained within 4.4 to 37.8 C.

Step 2 — Check Unit —

Upon receipt of shipment at

the jobsite, carefully check the shipment against the bill of

lading. Make sure all units have been received. Inspect the car-

ton or crating of each unit, and inspect each unit for damage.

Ensure the shipping company makes proper notation of any

shortages or damage on all copies of the freight bill. Concealed

damage not discovered during unloading must be reported to

the shipping company within 15 days of receipt of shipment.

NOTE: It is the responsibility of the purchaser to file all

necessary claims with the shipping company.

1. Verify unit is correct model for entering water tempera-

ture of job.

2. Be sure the location chosen for unit installation provides

ambient temperatures maintained above freezing. Well

water applications are especially susceptible to freezing.

3. Be sure the installation location is isolated from sleeping

areas, private offices and other acoustically sensitive

spaces.

NOTE: A sound control accessory package may be used

to help eliminate sound in sensitive spaces.

4. Provide sufficient access to allow maintenance and

servicing of the compressor and coils.

5. Provide an unobstructed path to the unit within the closet

or mechanical room. Space should be sufficient to allow

removal of unit if necessary.

6. Provide ready access to water valves and fittings, and

screwdriver access to unit side panels.

7. Where access to side panels is limited, pre-removal of the

control box side mounting screws may be necessary for

future servicing.

STORAGE — If the equipment is not needed for immediate

installation upon its arrival at the jobsite, it should be left in its

shipping carton and stored in a clean, dry area of the building

or in a warehouse. Units must be stored in an upright position

at all times. If carton stacking is necessary, stack units a maxi-

mum of 3 cartons high. Do not remove any equipment from its

shipping package until it is needed for installation.

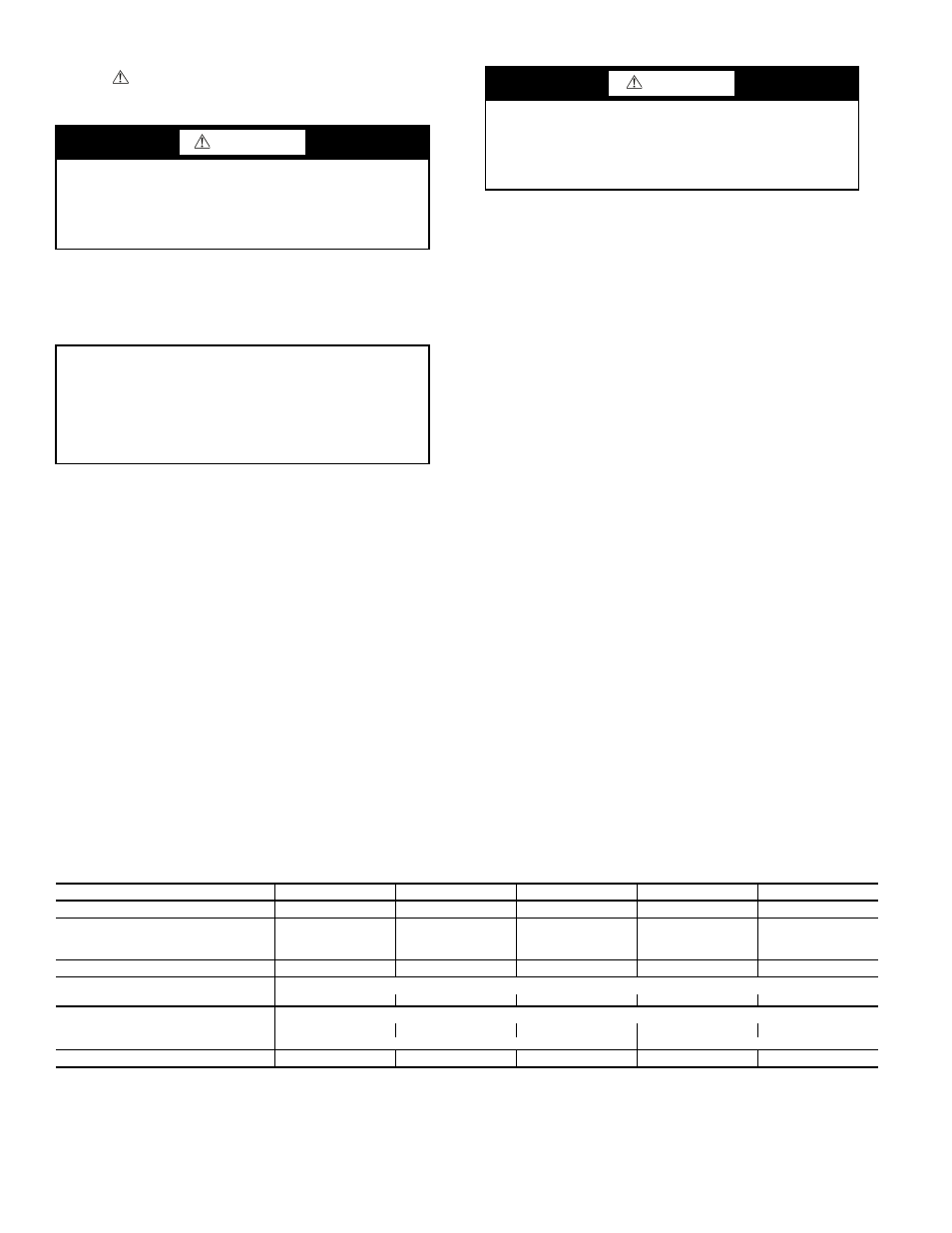

Table 1 — 50PSW Unit Physical Data

LEGEND

NOTES:

1. Maximum working pressure on the base unit is 3445 kPa.

2. Units have a dual isolated compressor mounting.

3. Units have a balanced port expansion valve (TXV).

4. Insulated source and load water coils are standard.

5. Insulated refrigerant circuit is standard.

6. Compressor is on (green) light and fault on (red) light.

WARNING

Electrical shock can cause personal injury or death. Before

installing or servicing system, always turn off main power

to system. There may be more than one disconnect switch.

Turn off accessory heater power if applicable. Install lock-

out tag.

IMPORTANT: The installation of water source heat pump

units and all associated components, parts, and accessories

which make up the installation shall be in accordance with

the regulations of ALL authorities having jurisdiction and

MUST conform to all applicable codes. It is the responsi-

bility of the installing contractor to determine and comply

with ALL applicable codes and regulations.

CAUTION

To avoid equipment damage, do not use these units as a

source of heating or cooling during the construction pro-

cess. The mechanical components used in these units can

quickly become clogged with construction dirt and debris

which may cause system damage.

50PSW UNIT SIZE

036

060

120

180

360

NOMINAL CAPACITY (kW)

10.5

17.6

35.2

49.2

105.5

WEIGHT (kg)

Operating

158

163

329

358

604

Packaged

169

175

349

363

608

COMPRESSOR (qty)

Scroll (1)

Scroll (1)

Scroll (2)

Scroll (1)

Scroll (2)

REFRIGERANT TYPE

R-410A

Factory Charge Per Circuit (kg)

2.04

2.83

2.83

6.80

6.80

CONNECTIONS, FPT (in.)

Commercial Load/Source

3

/

4

1

1

1

/

2

2

2

HWG Water In/Out

1

/

2

N/A

WATER VOLUME (L)

3.64

5.04

10.02

13.27

25.44

HWG — Hot Water Generator