3 calibrating the 920i – Rice Lake RailBoss Rail Scales - Installation Manual User Manual

Page 16

12

Railboss Railroad Track Scale

Use the following steps to properly trim the JB4SP junction box.

1. Make sure jumpers are in place to enable

trimming of the cells corresponding to each

load cell. See Figure 5-2 for the location of

jumpers JP1, JP2, JP3, and JP4.

2. Set all potentiometers fully clockwise to give

maximum signal output from each cell (see

Figure 5-2 for location of potentiometers)

3. Zero the indicator and place the RailBoss

Calibrator over each load cell in turn. The

amount of test weight is recommended to be

30,000 lb.

4. Record the value displayed on the indicator

after the calibrator is placed in turn on each

load cell. Allow the scale to return to zero each

time to check for friction or other mechanical

problems. Select the load cell which has the

lowest value as your reference point. This cell

will not be trimmed.

5. Replace the same test load over each cell in

turn. Using the corresponding potentiometer,

trim each cell down to equal the reference load

cell. check all cells again for repeatability and,

if necessary, repeat Steps 3 and 4.

6. Pull excess cable out of the enclosure and

tighten the cord grip assemblies with a wrench.

To be watertight, each cord grip must be

tightened so the rubber sleeve begins to

protrude from the hub.

7. Unused hubs must be properly plugged to

prevent moisture entry. See Rice Lake’s

Electronic Replacement Parts Catalog to order

extra hole plugs.

8. Remove the desiccant from the plastic bag, and

insert the desiccant bag into the junction box

before closing. Inspect the desiccant during

normal service and change as needed.

9. Replace the cover and torque the cover screws

in an alternating pattern. Torque to 15 in/lb to

be certain the gasket is compressed equally in

all locations.

5.3

Calibrating the 920i

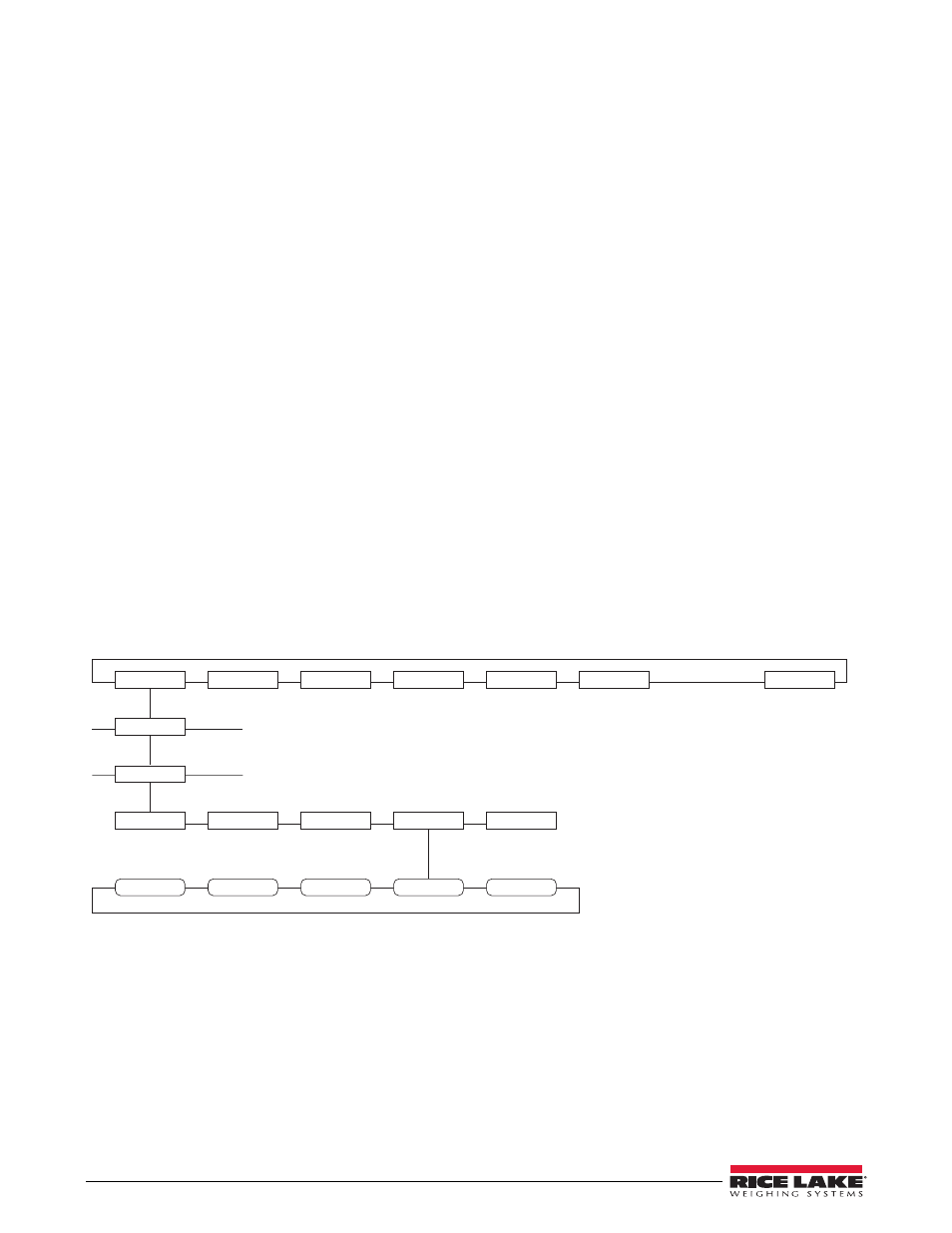

The 920i can be calibrated using the front panel, serial commands, or iRev 4. Each method consists of the

following steps:

•

Zero calibration

•

Entering the test weight value

•

Span calibration

SCALES

SERIAL

FEATURE

PFORMT

SETPTS

DIG I/O

VERS

SCALE 1

CALIBR

WZERO

WVAL

WSPAN

WLIN

REZERO

POINT 4

POINT 5

POINT 1

POINT 2

POINT 3

Figure 5-5. Calibration (CALIBR) Submenu