Do not – Rice Lake MSI6260cs Digital Crane Scale Operator Manual User Manual

Page 3

MSI-6260CS Crane Scale™

•

User Guide Page 3

MEASUREMENT SYSTEMS INTERNATIONAL

Rev 1 4/14/06 for SW Ver 5-xx

SECTION 1 – INTRODUCTION & INSTALLATION

INTRODUCTION

The MSI-6260CS Crane Scale is a member of the Measurement Systems International (MSI) CellScale system.

CellScale™, the system’s central weighing and communication controller, gives you an unprecedented founda-

tion for building your weighing system. For the first time, your weighing system may expand to virtually any

combination of load sensors, weight displays and other data recorders — without requiring cables. In com-

bination with other CellScale equipment and software, the 6260CS can form the basis for intelligent process

control, material inventory systems, and material handling systems.

The 6260CS is available in a wide range of standard weighing capacities from 500 lb (250kg) to 100000 lb

(50000 kg). In addition, MSI has designs for capacities as high as 500 tons as well as custom in-block systems

for any type of crane.

INSTALLATION

The 6260CS features a heavy duty, cast aluminum enclosure rated at NEMA

4 IP 65. The 6260CS installs easily by hanging it on the crane, using properly

sized shackles. Please refer to MSI’s brochure, “Crane Safety” when install-

ing model 6260CS.

One of the most common installation problems is using an oversize shackle

or too large a hook to interface with the 6260CS. This can cause off center

loading and stress points that will reduce the life of the 6260CS lifting eye

or hook. Use the appropriate interface hardware for the capacity of the scale.

If your interface hardware does not fit properly, MSI can supply the 6260CS

with oversize lifting eyes or shackle interfaces. If the crane hook is too large

to fit in the lifting eye with single point interface, then install the scale using

adaptive rigging.

If multiple attachments are needed, use a shackle or ring to attach the mul-

tiple lines to thus keeping a single point attachment to the scale. Single point

attachments are necessary to ensure the safety and accuracy of the scale

system.

Regular maintenance inspections of the lifting system should be performed to

ensure safety. Pay particular attention for signs of stress on any element in the

load train.

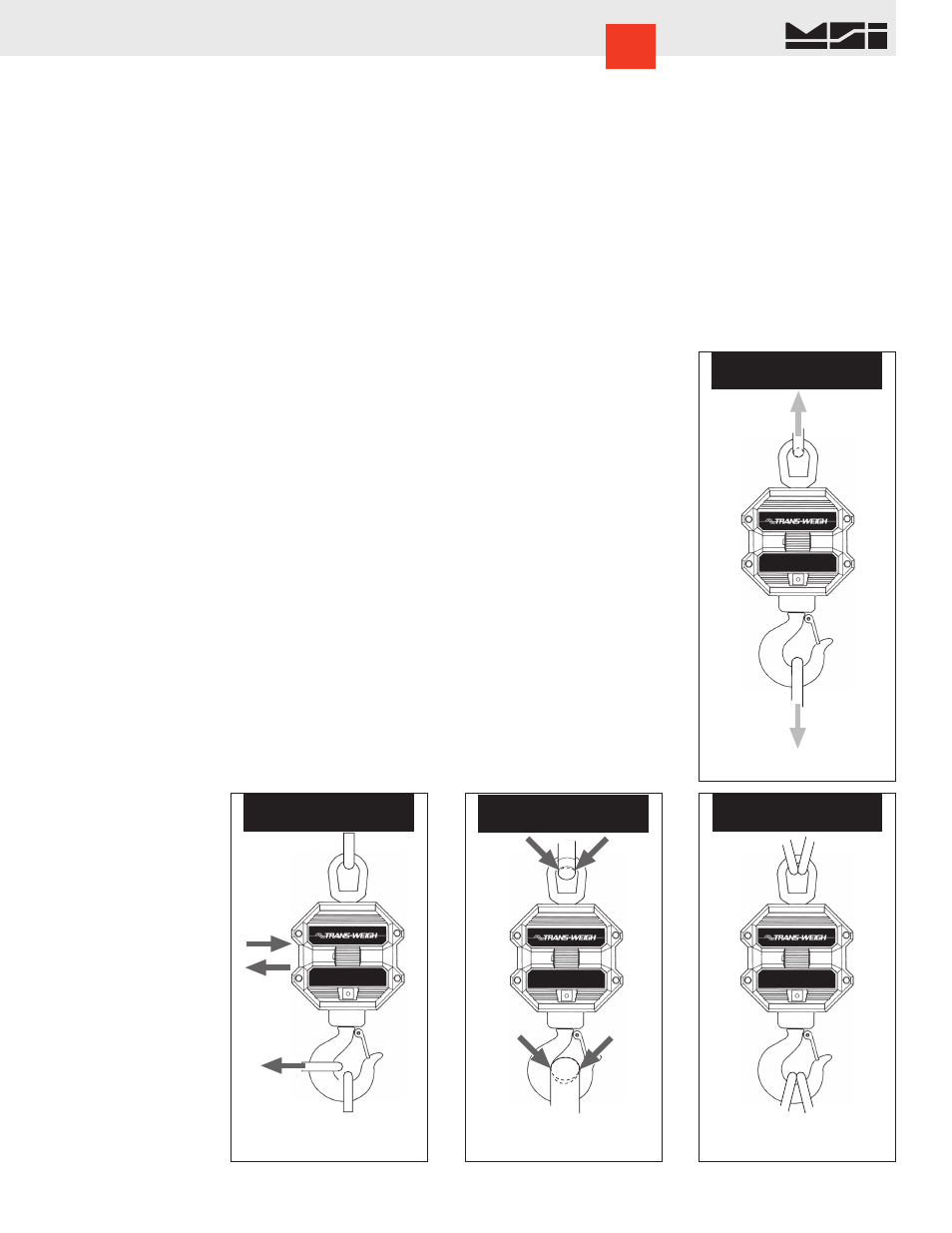

DO NOT

1. DO NOT PUSH OR PULL ON LOADED SCALE.

2. DO NOT PULL LATERALLY ON HOOK WITH

SCALE LOADED.

DO

USE HARDWARE THAT CREATES SINGLE

POINT ATTACHMENTS AND ALLOWS THE

SCALE FREEDOM OF ALIGNMENT.

DO NOT

DO NOT INTERFACE HARDWARE

(SHACKLES, HOOKS ETC.) THAT ARE

OVERSIZED AND RESTRICT SINGLE POINT

LOADING AND SELF-ALIGNMENT WHICH

CAN RESULT IN OFF-AXIS LOADING.

DO NOT

DO NOT USE MULTIPLE ATTACHMENTS.