Rice Lake AutoLift HE Low-Profile Lift User Manual

Installation manual, Roughdeck, He autolift

Table of contents

Document Outline

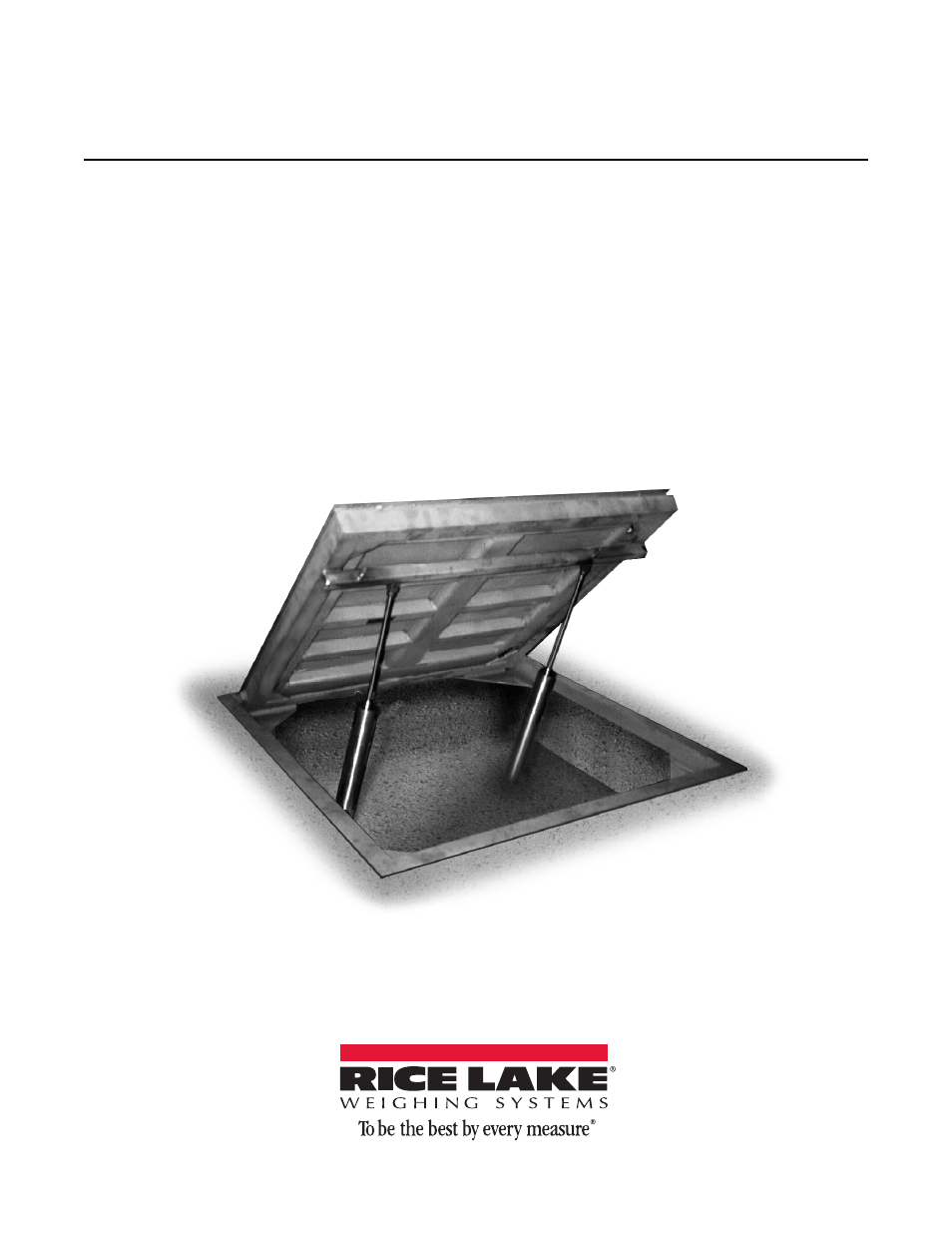

- RoughDeck HE AutoLift

- Low-Profile Floor Scale With Pneumatic Lifting Devices

- Installation Manual

- 44141 Rev D

- Contents

- About This Manual 1

- RoughDeck HE AutoLift Option Limited Warranty 15

- © Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

- Specifications subject to change without notice.

- Rice Lake Weighing Systems is an ISO 9001 registered company.

- November 17, 2014

- About This Manual

- 1.0 Introduction and System Setup

- 2.0 Installation

- 2.1 Overview

- 2.2 Site Preparation

- 2.3 Unpacking

- 2.4 Electrical Interface to Indicator

- Bare

- #1 (Shield)

- White

- #2 (-Signal)

- Green

- #3 (+Signal)

- Blue

- #4 (-Sense)

- Black

- #5 (-Excitation)

- Yellow

- #6 (+Sense)

- Red

- #7 (+Excitation)

- 4X4

- 63.06

- 49.06

- 49.00

- 63.00

- 41936

- 15.00

- 5X5

- 75.06

- 61.06

- 61.00

- 75.00

- 41397

- 16.75

- 4X6

- 63.06

- 49.06

- 73.00

- 87.00

- 15.00

- Table 2-2: Reference to Figure 2-4 on page 5.

- Figure 2-1. Example Pit Installation Drawing

- 2.6 Cylinder/Platform Installation

- 1. Fit the pivoting intermediate frame over the hinge pins (Figure 2-2, B). The intermediate frame should be seated on the pit coping corner plates (Figure 2-2, C).

- 2. Attach the rod end of each cylinder to the intermediate frame support tube. The cylinder muffler should face upward toward the scale.

- 3. Adjust each cylinder rod until it is approximately 1" from the fully-retracted position (Figure 2-2, D). Place the pivot brackets (Figure 2-2, E) against the pit floor and use them as templates to mark the mounting hole locations. Be sure the air ...

- 4. Drill holes, install anchors, and secure the cylinder pivot brackets to the pit floor.

- 5. Attach the main air line to the inlet side of the regulator (Figure 2-2, F). Attach the air line from the outlet side of the regulator to the input fitting on the pneumatic control box (Figure 2-2, G).

- 6. Attach the air lines from the output fitting on the pneumatic control box to cylinders. Apply 85-100 psi air pressure to the cylinders. Check for air leaks.

- 7. Place the platform scale onto the intermediate frame (Figure 2-2, H), making sure feet sit on corner pads without rocking. Adjust feet as necessary so the platform is level to within 1/4".

- 8. Feed the load cell cables through the conduit. Leave a strain relief loop to allow enough cable for free movement of the scale in the lifted position without tension in the cables (Figure 2-2, J).

- 9. Route the load cell cables through the fittings in the junction box (Figure 2-2, K). Wire the cables to the junction box according to the corner numbering diagram (Figure ) and load cell wiring chart (Table 2-3). Coil and store excess cable before...

- 10. Adjust speed during the lift cycle using the up speed adjustment screw (Figure 2-2, L) in the pneumatic control box. Once you have achieved the desired speed, tighten the lock nut. Adjust descent speed using the down speed adjustment screw (Figur...

- Red

- +Excitation

- Black

- -Excitation

- Green

- +Signal

- White

- -Signal

- Base or Clear

- Shield

- 3.0 Adjustments and Calibration

- 4.0 Service Information