3 value, 4 setting a float value, 5 reading a float value – Rice Lake 880 Performance Series Panel Mount Indicator/Controller - ProfiNet Interface Option Installation and Programming Manual User Manual

Page 18: Value, Setting a float value, Reading a float value, Table 4-5

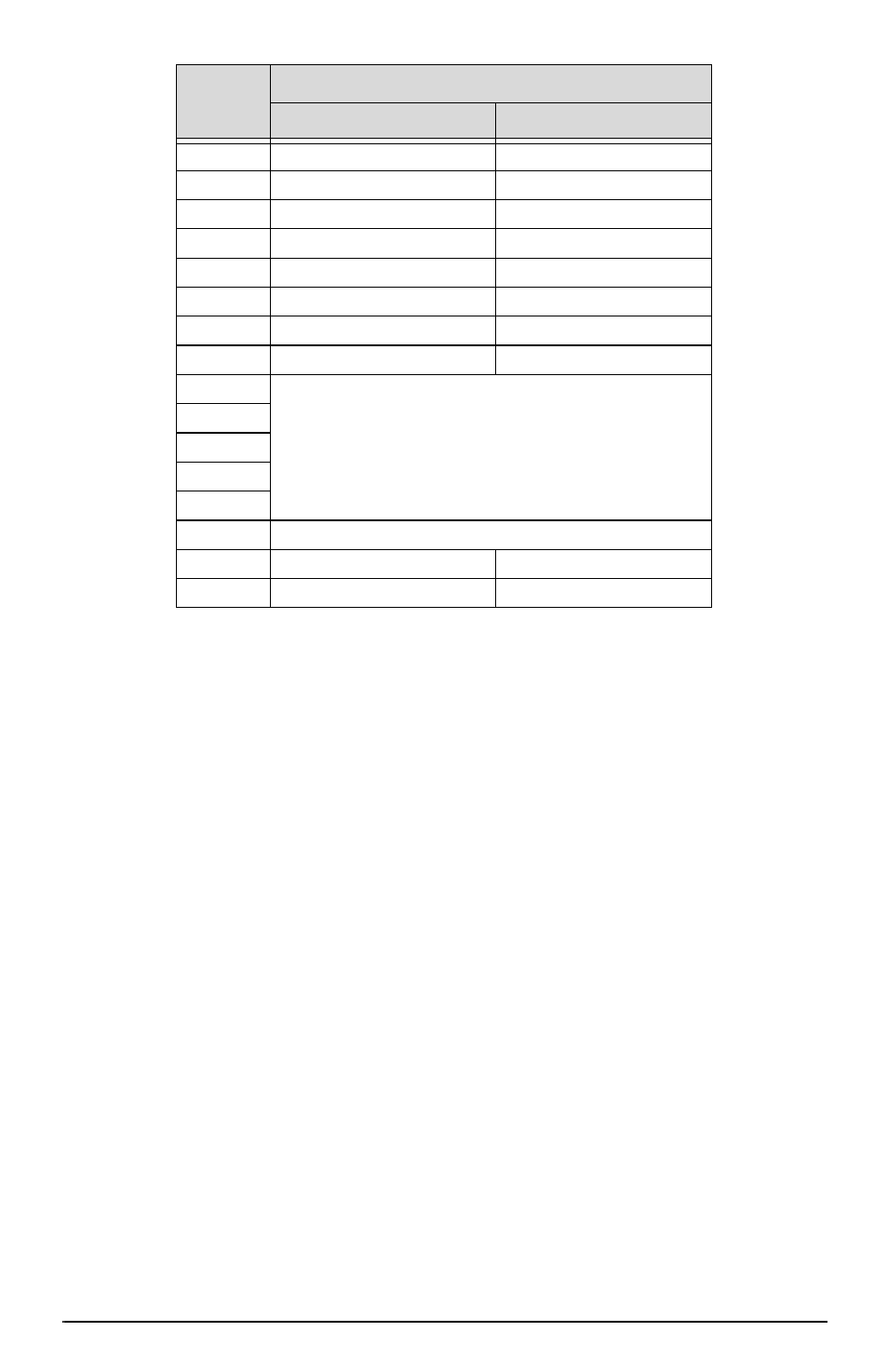

Table 4-5. Batch Function Status Data Format

Word 2

Bit

Batch Function Status Data

Value=0

Value=1

00

Digital input 4 OFF

Digital input 4 ON

01

Digital input 3 OFF

Digital input 3 ON

02

Digital input 2 OFF

Digital input 2 ON

03

Digital input 1 OFF

Digital input 1 ON

04

Batch not paused

Batch paused

05

Batch not running

Batch running

06

Batch not stopped

Batch stopped

07

Alarm OFF

Alarm ON

08

Setpoint number

09

10

11

12

13

Not used

14

Integer data

Floating point data

15

Positive weight

Negative weight

14 ProfiNet Installation and Programming Manual

4.2.3

Value

Weight data is returned to the master in the third and fourth words of the input

command format, depending on the command and the value type. The weight data

returned is the displayed weight after the command is executed, unless the command

specifies otherwise.

4.2.4

Setting a Float Value:

Setting a float value in a setpoint requires the value to be sent in two separate integer

values. Most PLCs have a mechanism to take a float value and separate it into to

integer values.

The following is what is needed in the output words to set the value of Setpoint #1 to

10000.

Command word = 304

Parameter word = 1

MSW = 17948

LSW = 16384

4.2.5

Reading a Float Value:

When a float value is read it will be retuned in two integers that will represent the

float value.

The PLC will need to combine MSW and LSW integer values back into a float value.

The following is what is will be returned in the input words if the weight on the scale

is 800.5.

Command Word = 288

Status word = Scale status

MSW= 17480

LSW = 8192