0 load cell trimming, 1 load cell trimming, 2 excitation trim – Rice Lake Z6 Single-Ended Beam, SS Welded-seal, IP67, OIML C3 User Manual

Page 16: Load cell trimming, 1 load cell trimming 8.2 excitation trim

12

Load Cell and Weigh Module Handbook

8.0

Load Cell Trimming

It may be necessary to trim the load cell outputs as a first step

before starting the calibration process. Trimming is performed

at the junction box to equalize the weight reading from all cells

in a system. This ensures that the scale weighs correctly

regardless of where the load is applied to the scale.

Trimming is necessary if:

1. It is a legal-for-trade weighing application.

*2. The location of the center of gravity of the contents is not

fixed, e.g., powder material which may accumulate on one

side.

*3. A high-accuracy weighing system is required.

Trimming is not necessary if:

4. Matched output load cells are used (as in the Paramounts).

5. Weighing self-leveling materials (liquids).

6. The vessel is partially supported on flexures.

*Assume that the vessel’s center of gravity (see 2 and 3

above) rises along the same vertical line as the vessel is filled.

Each load cell is always subjected to the same percentage of

the weight.

Trimming involves placing the same weight over each load cell

in turn, and adjusting the corresponding trim pot in the

junction box until the indicator reads the same for all cells. To

further illustrate load cell trimming, please review the following

examples of signal trim and excitation trimming procedures.

8.1

Load Cell Trimming

Many weighing systems use multiple load cells and therefore

require a summing junction box to tie or “sum” the load cell

signals together, allowing a digital weight indicator to read a

single “system” signal. The summing process actually wires

multiple load cells so that all their signal lines and excitation

lines are in parallel, providing instantaneous electronic

summing of the signals.

Load cell summing is necessary because:

•

Weight distribution in multiple load cell systems is

not equal at each load cell. The vessel loading

p r o c e s s , p r e s e n c e o f a g i t a t o r s , a n d t h e

characteristics of the material and many other

factors affect weight distribution on the load cells.

•

It is virtually impossible to make each load cell

exactly alike. Load cell manufacturing process

tolerances allow for some variance in individual cell

specifications. This variance, if unchecked, would

not allow for the kinds of accuracy required in

modern process applications.

There are two summing methods; Excitation trim and Signal

trim.

8.2

Excitation Trim

This is the oldest method of trimming the output from a strain

gauge load cell. Excitation trimming adds series resistance to

the excitation circuit of the load cell, thereby reducing the

excitation voltage at the cell. The load cell with the lowest mV/

V output receives the full excitation voltage. All other load cells

in the system with a higher mV/V output receive proportionally

smaller excitation voltages. This results in matched full load

outputs for all load cells in the system.

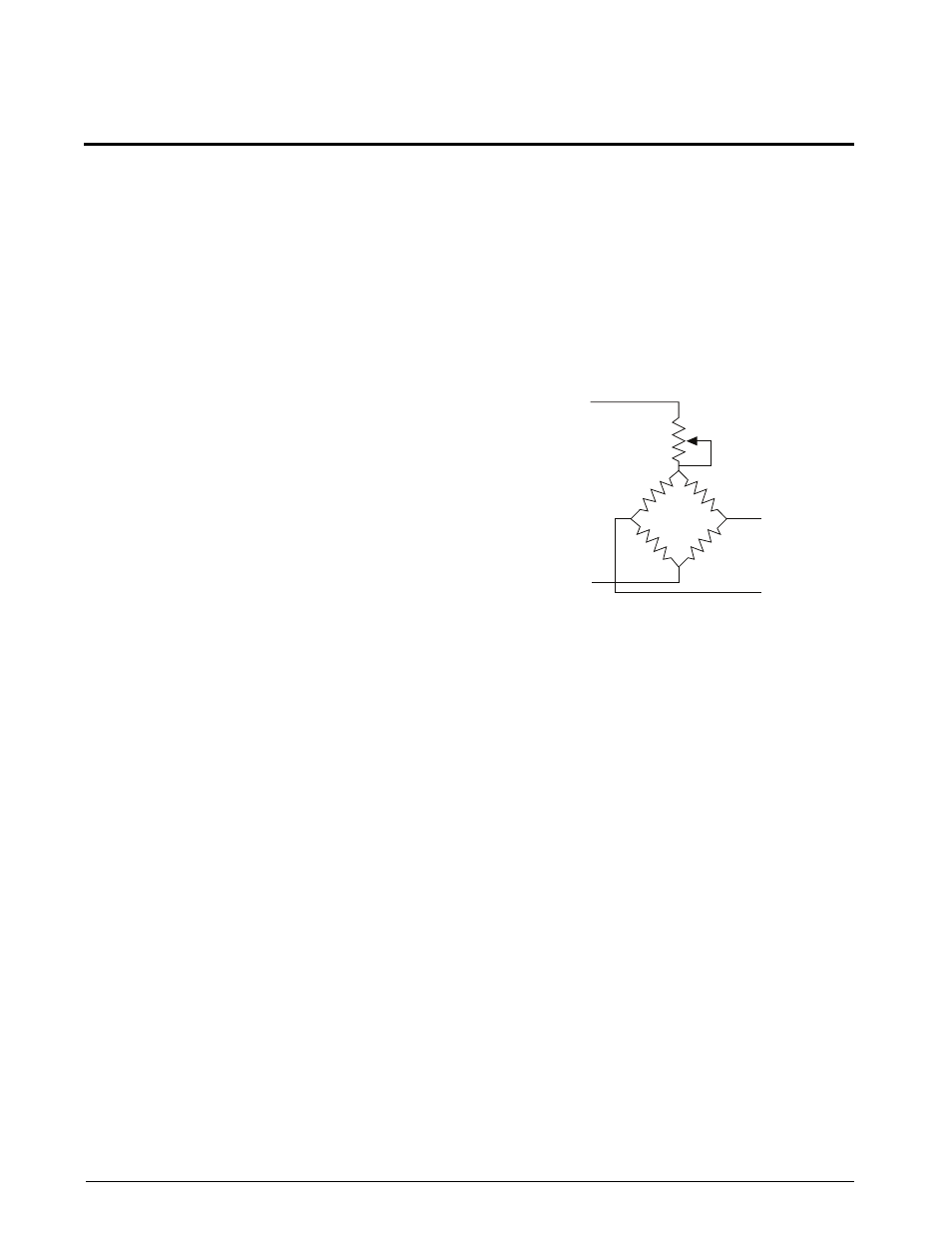

Figure 8-1 is a functional diagram of an excitation trim J-box.

Note that a variable resistor or potentiometer (pot), is inserted

in the + excitation lead of each load cell. If the pot is opened

so that resistance is zero, the full excitation voltage is applied

to the load cell. As resistance is increased, excitation voltage

decreases.

Excitation Trimming Procedure

The simplest method of trimming with excitation is to set up

your system, turn all trim pots to the “open” or full excitation

setting, and test each corner of the system with a calibrated

test weight or any dead weight. Once the lowest output

corner is located, the other cells are trimmed to match by

physically loading with the same weights and adjusting the

pots. This procedure can be practical if used in field

replacement of load cells in light-capacity floor scales. It is not

typically used in heavy-capacity scales where application of

test weights to corners in such a manner is not practical.

Another method is “pretrimming.” Here, the load cells are

trimmed by mathematically calculating the excitation voltage

for the load cell, then measuring the excitation voltage with a

voltmeter, while adjusting the pot to the required voltage. The

following five steps walk you through this procedure.

Figure 8-1. Excitation Trimming Load Cells

1.

Determine how much excitation voltage your

electronic digital weight indicator is supplying to the

load cells. This is found by measuring, with a

voltmeter, the actual excitation voltage present at the

reference cell’s excitation leads. For this example, we

will use 10 volts DC.

NOTE: The reference cell is the cell with the lowest mV/V

rating, as shown on its calibration certificate.

2.

Determine the exact mV/V rating of each load cell

and locate the cell with the lowest rating. The exact

mV/V rating is found on the calibration certificate

supplied with the load cell or on the label itself. Just

because a cell is rated at 3 mV/V, don’t assume it’s

exactly 3 mV/V.

#1 = 2.997 mV/V #3 = 2.999 mV/V

#2 = 3.003 mV/V #4 = 3.002 mV/V

Cell number 1 has the lowest rating at 2.997 mV/V.

3.

Calculate the trimming factor by multiplying the

lowest mV/V by the excitation voltage.

2.997 mV/V x 10V = 29.970 mV

4.

Calculate the adjusted excitation voltage for the

remaining load cells and adjust each respective trim

pot to the appropriate voltage level.

#1 = leave alone, lowest mV/V

#2 = 29.97 mV ÷ 3.003 mV/V = 9.980 volts

#3 = 29.97 mV ÷ 2.999 mV/V = 9.993 volts

#4 = 29.97 mV ÷ 3.002 mV/V = 9.983 volts

The scale is now trimmed.

5.

Verify your results with certified test weights or a

known amount of material.

TRIM POT

EXCITATION

SIGNAL

+

−

+

−

- UB6 S-Beam, SS, Hermetically-sealed, IP68, OIML C3 UB1/UB1 HE S-Beam, Stainless Steel TWM Tank Weighing Module THC Single-Ended Beam, Stainless Steel Tension Canisters Tedea-Huntleigh Single Points Tedea-Huntleigh Compression Canisters Tedea-Huntleigh T3P1 Tension Canister, Alloy Steel T2P1 Tension Canister, Alloy Steel STC, Low-Capacity, Alloy Steel STC SS S-Beam, Stainless Steel, IP67 STC S-Beam, Alloy Steel SSB Single-Ended Beam, Stainless Steel SQB-HSS Single-Ended Shear Beam, Stainless Steel SQB Single-Ended Shear Beam, Alloy Steel SP4 Single Point, Aluminum SLB Single-Ended Beam, Stainless Steel Single-Ended Beams Single Points SHB Single-Ended Beam, Stainless Steel Sensortronics Single Points Sensortronics Compression Canisters Sensortronics SEB Single-Ended Beam, Alloy Steel, OIML, IP67 S-Beam SB6 Single-Ended Beam, Stainless Steel, OIML C3 SB5 Single-Ended Beam, Stainless Steel SB4 Single-Ended Beam, Stainless Steel SB3 Single-Ended Beam, Alloy Steel SB14 Single-Ended Beam, Stainless Steel SB10 Single-Ended Beam, Stainless Steel S35 Universal, Stainless Steel RTM Stainless Steel Tank Weigh Module RSC S-Beam, SS NTEP 1:3000 Class III Single Cell RLSSB Single-Ended Beam, Stainless Steel RLSP4 Aluminum RLSCA-50K Rocker Column, Stainless Steel RLSBF Single-Ended Beam, Stainless Steel, IP67 RLSB2L/RLSB2M/RLSB2MLW Single-Ended Beam RLSB250/RLSB250T Single-Ended Beam, Stainless Steel RLSB2 Single-Ended Beam, Alloy Steel RLPWM16 Single-Point, Aluminum RLPWM15HE Single Point, Stainless Steel RLPWM15, Single Point, Stainles Steel RLPWM12 Single-Point, Aluminum RLPCBC-60 Stainless Steel RLPC6 Single-Point, Stainless Steel RLMK21 Single-Point, Stainless Steel RLMK1 Single-Point, Alloy Steel RLHTO Single-Ended Beam, Stainless Steel, OIML C3 RLHBB Single-Ended Beam, Stainless Steel RLH35 Single-Ended Beam, Stainless Steel RLETS S-Beam, Alloy Steel, IP67 RLETB Single-Ended Beam, Alloy Steel, OIML C3 RLDB50000S Double-Ended Beam, Stainless Steel RLCSP1 Compression Canister, Stainless Steel RLC Compression Canister, Stainless Steel RLBLP Planar Beam RLBLC Single-Ended Beam, Stainless Steel RL90000 Compression Disk, Alloy Steel RL8C2P1SS Compression Canister, Stainless Steel RL800WT Single-Point, Stainless Steel RL75223 Double-Ended Beam, Alloy Steel RL75114 Rocker Cell, Alloy Steel RL75060S Double-Ended Beam, Stainless Steel RL75058 Double-Ended Beam, Alloy Steel RL75040 Double-Ended Beam, Alloy Steel RL75016WHE Double-Ended Beam, Stainless Steel RL75016 SS Double-Ended Beam, Stainless Steel RL75016 Double-Ended Beam, Alloy Steel RL70000 SS Double-Ended Beam, Stainless Steel RL70000 Double-Ended Beam, Alloy Steel RL60040SST Single-Ended Beam, Stainless Steel, IP65 RL50210SS Single-Ended Beam, Stainless Steel, IP65 RL50210 Single-Ended Beam, Alloy Steel RL40BBS Single-Ended Beam, Alloy Steel RL39123 Single-Ended Beam, Stainless Steel RL35083 Single-Ended Beam, Stainless Steel RL35082 Single-Ended Beam, Stainless Steel RL35023S Single-Ended Beam, Stainless Steel RL35023 Single-Ended Beam, Alloy Steel RL30745 Single-Ended Beam, Stainless Steel RL30000 Single-Ended Beam, Alloy Steel RL2010 Tension Link, Stainless Steel RL20001 S-Beam, Alloy Steel RL20001 HE S-Beam, Stainless Steel RL20000 ST S-Beam, Stainless Steel RL20000 SS S-Beam, Stainless Steel RL20000 S-Beam, Alloy Steel RL1855HE Weigh Modules RL1521A Single-Point, Aluminum RL1385 Single-Point, Stainless Steel RL1380 Single-Point, Stainless Steel RL1260 Single-Point, Aluminum RL1250 Single-Point, Aluminum RL1140 Potted Single Point, Stainless Steel RL1042 Single-Point, Aluminum RL1040 Single-Point, Alumuinum RL1010 Single-Point, Aluminum S-Beams Compression Canisters Revere Transducers Single Point Revere Transducers S-Beams Revere Transducers Compression Canisters Revere Transducers Revere RC3 Rocker Cell, Stainless Steel RC1 Rocker Column, Stainless Steel PWS Single Point, Stainless Steel PW6K Single-Point, Aluminum, IP65 PW27 Single Point, Stainless Steel PW25 Single Point, Stainless Steel PW2 Single Point, Aluminum, IP65 PW16 Single Point, Aluminum PW15AH Single Point, Stainless Steel PW15 Single Point, Stainless Steel, IP67 PW12 Single Point, Aluminum PSD Compression Disk, Alloy Steel, OIML, C3 POD1 Weigh Module, Aluminum IP65 PCB Single Point, Stainless Steel, IP69 PC6 Single Point, Stainless Steel Hermetically-sealed, IP68 PC2 Single Point, Stainless Steel Hermetically-sealed, IP68 PC1 Single Point, Stainless Steel PB Planar Beam, Aluminum IP65 OIML Motor Truck Scale Electronic Conversion Kit Mettler Toledo DigiTOL Retrofit Kit MBB Single-Ended Beam, Alloy Steel LPS Single Point, Aluminum LOC Single Point, Aluminum LOC LE Single Point, Aluminum, Heavy Capacity Load Cells - Weigh Module LCD Compression Disk, Alloy Steel, IP67 JRT Torsion Ring Transducer, Alloy Steel/Stainless Steel Interface Compression Canisters HTC HSS S-Beam, Stainless Steel, Welded-seal, IP67 HPSM Single Point, Stainless Steel HPS Single Point, Stainless Steel, Welded-seal, IP67 HOC Single Point, Aluminum HBM Single Points HBM S-Beams HBM Compression Canisters HBM HBB Single-Ended Beam, Stainless Steel, Welded-seal, IP67 H35 Single-Ended Beam, Stainless Steel Flintec Single Points Flintec S-Beams Flintec Compression Canisters Flintec DSR-HSS Double-Ended Shear Beam SS, Welded-Seal, IP67 DSR Double-Ended Shear Beam, Alloy Steel, IP67 Double-Ended Beams DLB Double-Ended Beam, Alloy Steel CSP Compression Canister, Stainless Steel CSB Double-Ended Shear Beam, Alloy Steel CP Compression Canister, Stainless Steel, Welded-seal, IP68 CLB Double-Ended Beam, Alloy Steel Celtron Single Points Celtron S-Beams Celtron Compression Canisters Celtron Canisters C3P1 Compression Canister, Alloy Steel, IP67 C2P1 Compression Canister, Alloy Steel C16 Rocker Column Pin, Stainless Steel BSP S-Beam, Stainless Steel BLH Compression Canisters BLF Single-Ended Beam, Stainless Steel BLC Single-Ended Beam, Stainless Steel BK2 Single-Ended Beam, Stainless Steel BBS Single-Ended Beam, Alloy Steel B35 Single-Ended Beam, Stainless Steel A35 Single-Ended Beam 9803 Link Beam, Stainless Steel 9523 Single-Ended Beam, SS, Welded-seal, IP67 9423 Link Beam, Stainless Steel 9363 S-Beam, Stainless Steel 9323 Link Beam, Stainless Steel 9223 Link Beam, Stainless Steel 92 Compression Canister, Alloy Steel, Welded-seal, IP68 9123 Single-Ended Beam, Stainless Steel 9103 Double-Ended Beam, Stainless Steel 9102 Single-Ended Beam, Stainless Steel 9010 Single Point Fluid Damped Load Cell 792 Compression Canister, Stainless Steel, IP68 65114 Rocker Column, Stainless Steel 65083 Single-Ended Beam, Stainless Steel, Welded-seal, IP67 65083 S Single-Ended Beam, Stainless Steel 65061A Double-Ended Beam, Alloy/Stainless Steel 65059 Vishay Sensortronics 50-500 lb Capacities - Load Cell/Weigh Module Handbook 65059 Vishay Sensortronics 1000-2500 Capacity - Load Cell/Weigh Module Handbook 65059 Mild Steel Single Module (Includes Load Cell) - Load Cell/Weigh Module Handbook 65059 Mild Steel 4-Module Kit - Load Cell/Weigh Module Handbook 65059 Mild Steel 3-Module Kit - Load Cell/Weigh Module Handbook 65058 S Double-Ended Beam, Stainless Steel 65058 Double-ended Beam, Alloy Steel 65040A-1127W Double-Ended Beam, Alloy Steel 65040A Double-Ended Beam, Alloy Steel 65040 S Double-Ended Beam, Stainless Steel 65023A-5507 Single-Ended Shear Beam, Alloy Steel 65023A-5297 Single-Ended Shear Beam, Alloy Steel 65023A-5107-10 Single-Ended Shear Beam, Alloy Steel 65023A Single-Ended Shear Beam, Alloy Steel 65023 SS Single-Ended Beam, SS, Threaded and Thru, IP67 65023 S Single-Ended Shear Beam, Stainless Steel 65016WH Double-Ended Beam, SS Hermetically-sealed, IP68 65016W Double-Ended Beam, Stainless Steel, Welded-seal, IP67 65016 Double-Ended Beam, Alloy Steel, IP67 620 S-Beam, Stainless Steel, IP67 60063 S-Beam, Stainless Steel, IP67 60060 Single Point, Aluminum, Clear Anodized, IP67 60051 Single Point Beam, Stainless Steel, IP67 60050 S-Beam, Stainless Steel, IP67 60048 SS Single Point, Stainless Steel, IP67 60040 Single-Ended Beam, Alloy Steel, IP65 60001 S-Beam, Alloy Steel, IP67 5723 Link Beam, Alloy Steel 5223 Link Beam, Alloy Steel 5123 Single-Ended Beam, Alloy Steel 5103 Double-Ended Beam, Alloy Steel 5102 Single-Ended Beam, Alloy Steel, IP67 462 Single Point, Alloy Steel, IP67 363 S-Beam, Alloy Steel 355 Single-Ended Beam, Stainless Steel 3510-lbs Single-Ended Beam, Stainless Steel, IP68 3510-kg Single-Ended Beam, SS Welded-seal, IP68, OIML C3 3411/3421 Single-Ended Beam, Alloy & Stainless Steel 3200, Stainless Steel Compression Canister 240 Single Point Fluid Damped 220 Compression, Stainless Steel 1510 Single Point, Stainless Steel Welded-Seal, IP68 1320 Single Point, Aluminum 1260S Single Point, Aluminum 1260 Single Point, Aluminum 1250 Potted Single Point, Aluminum 1241 Single Point, Aluminum OIML C3 1240 Single Point, Stainless Steel 1200, Alloy Steel/Aluminum Compression Canister 1140 Potted Single Point, Stainless Steel 1130 Single Point, Stainless Steel 1042S Single Point, Aluminum 1042 Single Point, Aluminum 1040 Potted & Unpotted Single Point, Aluminum 1030 Single Point, Aluminum OIML C2.5 1022 Single Point, Aluminum 1010 Potted & Unpotted Single Point, Aluminum