Off-road gearing, On-road speed runs, Troubleshooting your speed-t – Losi LOSB0101 User Manual

Page 14

26

27

®

®

Standard Ball Differential Adjustment:

(optional, not included)

Never allow the diff to slip; that’s what the slipper is for. Before

trying to adjust your diff, you need to tighten the slipper until

the spring is fully compressed. Next set the diff setting so it is

on the tight side and break the diff in. How you break the diff

in is by placing one tire on the tabletop while the other tire is

off of the tabletop. Then give the truck about ¼ throttle for 30

seconds. Then do the same thing but place the opposite tire on

the tabletop while the other tire is in the air and give the truck

¼ throttle for another 30 seconds. Once that is done you can

set the diff. The diff setting will loosen up a little while it is still

breaking in and it is important for you to break the diff in prior

to driving the truck. Hold the spur gear and right rear tire, then

try turning the left rear tire forward. It should be very difficult

to turn the left rear tire. If the tire turns easily, the diff is too

loose. To tighten the diff, line up the slot in the diff screw with

the groove in the left out drive. Place the 1/16” Allen wrench

through both of these slots. This will lock the diff screw and the

out drive together. While holding the Allen wrench in place,

turn the right rear tire forward about 1/8 of a turn. Check the

differential adjustment again and repeat the tightening process

as necessary until the differential is no longer slipping. Do not

forget to reset the slipper setting. See “Slipper Adjustment” on

page 24, and then continue from here. The final differential

adjustment check should be made by placing the truck on

carpet, grass, or asphalt and “punching” (quickly applying)

the throttle. The differential should not slip. If it does, tighten

the diff in 1/8-turn increments as described above until the

slippage stops. Once the diff has been adjusted, it should still

operate freely and feel smooth. If the diff screw starts to get

tight before the diff is close to being adjusted properly (based

on slip), the diff should be disassembled and inspected; you

may have a problem with the differential assembly.

Breaking in the Differential:

While holding the chassis with only the left side tires firmly

on the ground, give the truck about one quarter throttle, for

10 seconds. The right side tires should spin freely during this

time. Repeat this with only the right side tires held firmly to the

ground, allowing the left tires to spin. Feel the differential (diff)

action and tighten slightly, if necessary. The differential should

have a tight, thick feel when rotating it after final adjustment.

CAUTION!

YOUR DIFFERENTIAL SHOULD NEVER BE ALLOWED TO SLIP

WHEN RUNNING (A SLIPPING DIFFERENTIAL CREATES A

“BARKING” SOUND). IF IT DOES, STOP IMMEDIATELY AND

TIGHTEN TO PREVENT DAMAGE.

Adjusting Gear Mesh

Incorrect gear mesh is the most common cause of stripped spur

gears. To set the gear mesh, one method is to cut a narrow strip

of notebook paper and thread it in between the gears. Loosen

the motor screws and slide the motor and pinion gear into the

spur gear. Retighten the motor screws and then remove the

strip of paper. Or you can loosen the motor and carefully slide

the motor leaving a small amount of backlash (play) between

the spur and pinion gears. It should not be tight and if you look

up-close there should be slight movement of the spur before

contacting the teeth on the pinion gear.

Gear Ratio

Changing the gearing provides you a quick and easy way to

tune the Speed-T. Use the temperatures of both the Xcelorin

motor and your battery pack as a guide to gearing to your

environment. When the Motor is above 160-170 degrees

Fahrenheit or the batteries are above 125-135 degrees

Fahrenheit, these are both strong indications that you should

drop the pinion size smaller. This would be a lower gear ratio

or larger number for example from 11.25 to 12.40. Going up

a pinion size is called gearing higher or a small number for

example 11.25 to 10.6 and will increase power consumption

and allow more speed.

Use the following formula to calculate the overall ratio for

combinations not listed on the gear chart:

Spur Gear Size

Pinion Gear Size

X 2.43 = Final Drive Ratio

When using higher gear ratios, it is extremely important to

monitor the temperatures of the battery and motor. If the

battery is extremely hot, and/or the motor is so hot that you

cannot touch it, most likely you are over-geared and drawing a

lot of current.

The gear combination that comes on the Speed-T (20-tooth

pinion / 88-tooth Spur) provides high-speed running intended

for hard surfaces, and this gearing is not recommended for

off-road, running in grass or constant starting and stopping.

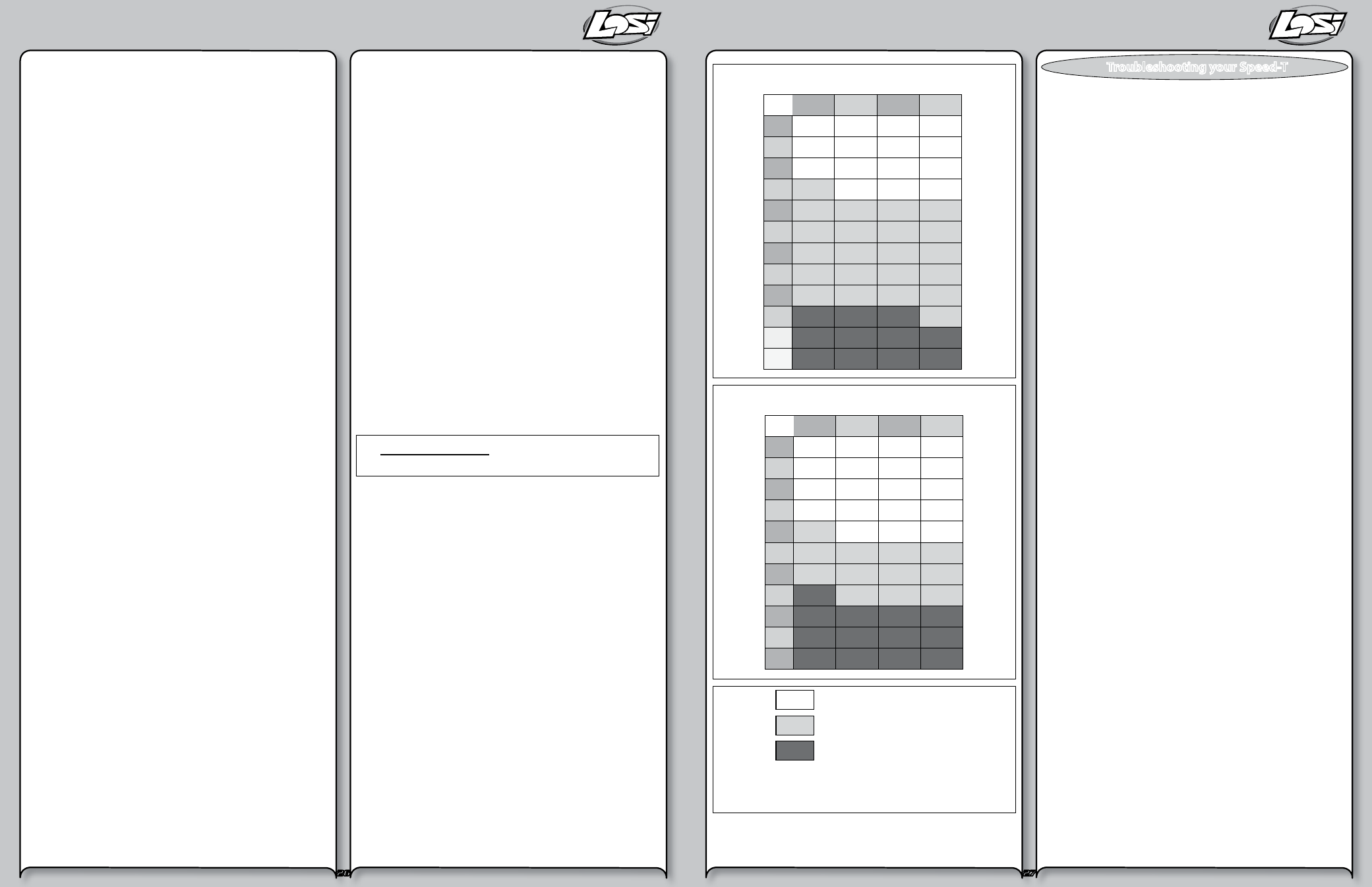

The following Gearing Tables will provide you a starting point

to gear the Speed-T for your desired running surface. Ambient

temperature and humidity along with the condition of your

equipment play a considerable role in performance.

Use the gear ratio charts and legend to aid in determining the

correct pinion and spur for your Speed-T.

Storage

When you are through running the model for the day

•

Blow it off with compressed air or use a soft bristled paint

brush to dust-off the vehicle.

•

Always disconnect and remove the battery from the

model whenever the model is stored. If the model will

be stored for a long time, then also remove the batteries

from the transmitter.

Off-Road Gearing

84

86

88

90

12

13

15

17

19

21

23

22

20

18

16

14

17.01

17.42

17.82

18.23

15.70

16.08

16.45

16.82

14.58

14.93

15.27

15.62

13.61

13.93

14.26

14.58

12.76

13.06

13.37

13.67

12.01

12.29

12.58

12.86

11.34

11.61

11.88

12.15

10.74

11.00

11.25

11.51

10.21

10.45

10.69

10.94

9.72

9.95

10.18

10.41

9.28

9.50

9.72

9.94

8.87

9.09

9.30

9.51

See Note 1

On-Road Speed Runs

84

86

88

90

15

17

19

21

23

22

20

18

16

14

14.58

14.93

15.27

15.62

13.61

13.93

14.26

14.58

12.76

13.06

13.37

13.67

12.01

12.29

12.58

12.86

11.34

11.61

11.88

12.15

10.74

11.00

11.25

11.51

10.21

10.45

10.69

10.94

9.72

9.95

10.18

10.41

9.28

9.50

9.72

9.94

8.87

9.09

9.30

9.51

24

8.51

8.71

8.91

9.11

Safe

Use Caution

Not Allowed

Safe

Use Caution

Not Allowed

Supplied Gear Ratio:

10.69

Note 1: If using 3S LiPo battery for off-road

do not use larger than a 18t pinion gear (Not Included).

Many questions are the result of simple user errors or minor

adjustments which are easily addressed. If after reading below

you cannot resolve your problem, then please call Horizon

Product Support at 1.877.504.0233.

Radio system does not work properly:

If the power light on the transmitter is not turning on, first

ensure the batteries are installed correctly. You should also

check that the batteries are good and/or if rechargeable are

fully charged. Replace them if needed. If the power light is

blinking, then the transmitter batteries are weak and should be

replaced. If the transmitter light is on but the radio is still not

responding, you may need to re-bind the transmitter to the

receiver. Please see page 16.

Short radio range:

If the radio range appears short, make sure the batteries are all

fully charged and/or are in good condition.

Steering works but the motor will not run:

The speed control may have gotten too hot and thermally shut

down (see page 18). Allow time for the speed control to cool.

If this is the problem and has happened a few times, consider

using a smaller pinion or a larger spur gear.

Check the transmission, do the rear wheels spin easily?

Check that a motor wire has not come loose.

Verify that the electronic speed control is plugged into the

throttle channel of the receiver.

Check using another battery. Contact Horizon support for

service instructions.

Steering servo does not work:

Check all wires, radio system, battery connectors, and the

battery pack.

Contact Horizon support for service instructions.

Motor runs backwards:

Looking directly at the end of the motor the wires attached to

the left most should be the Black wire, the center Blue, and the

far right should be White. If not please correct. If you are still

experiencing problems please contact Horizon support.

Motor starts running immediately after the battery has

been connected.

There may be internal ESC damage. Contact Horizon

Product Support.

Troubleshooting your Speed-T