Losi LOSA0887 Mach .15RE Manual User Manual

Mach .15re owner’s manual

Congratulations on your purchase of a Mach 15RE

engine! Precision manufactured and assembled, your

Mach 15RE will provide you with trouble-free

performance if you read and follow these instructions.

Using the Proper Fuel and Glow Plug

Using the proper fuel and glow plug is critical in order to

achieve maximum performance and reliability. You must

use fuel, glow plugs and air filters that are specifically

designed for model car/truck/buggy applications. Never

use any type of model airplane glow fuel. Use

of model airplane fuel will damage your engine and

immediately void any warranty.

We recommend using Blue Thunder or Blue Thunder

Race Formula blend fuels with 20% nitro, providing the

best combination of power and fuel economy. Dynamite

®

Blue Thunder Fuels are vigorously tested, researched

and formulated to deliver excellent power as well as

engine protection.

A glow plug has been included and is ideal for breaking-in

your new engine. In fact during the break-in procedure, it is

not uncommon to go through one or two glow plugs, as

microscopic bits of metal (from the cylinder/piston wearing

in) bond themselves to the plug element causing glow plug

failure. We recommend the Dynamite MC-59 McCoy

Power Plug (DYN2508) as the absolute best glow plug for

this engine. Delivering an ideal balance of performance and

longevity, this is the same glow plug that continues to win

races at every level of competition, from local events to

World Championships.

All car engines must use a properly oiled air filter to keep

dirt out of the engine. Any dirt that enters the carburetor

can immediately destroy your engine! We recommend

DYN2503 or DYN2504 as excellent choices for quality

air cleaners.

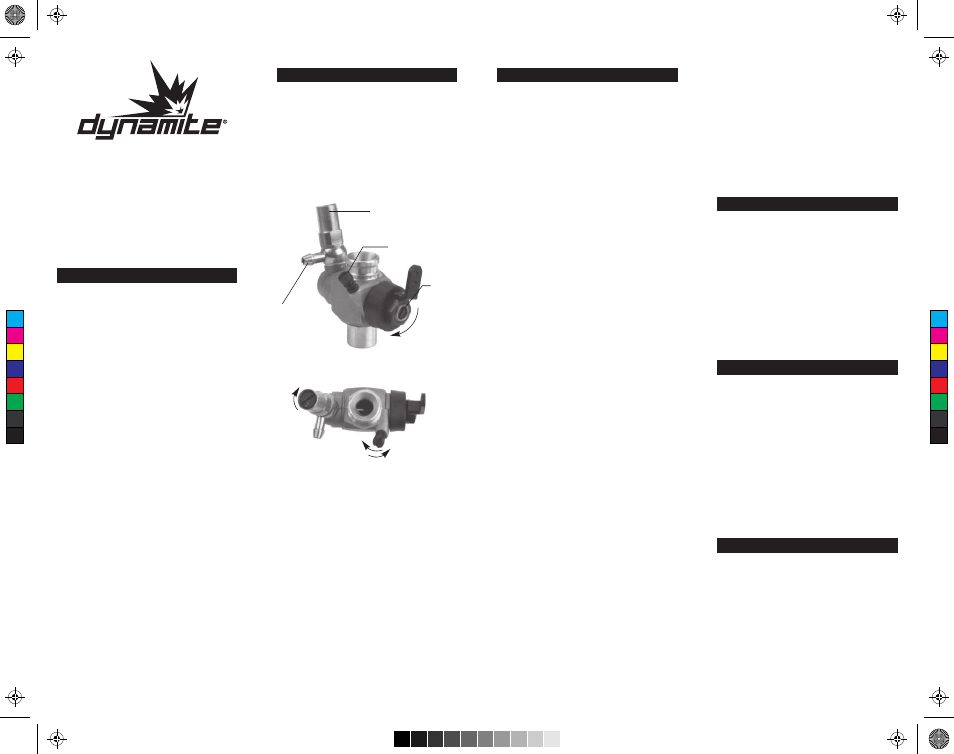

Carburetor Adjustments

Your Mach 15 RE engine comes equipped with a

precision rotary-type carburetor. Take a moment to review

the pictures below to familiarize yourself with the various

functions of the carb. Loosening the nut located on the

side of the crankcase under the carburetor body will allow

you to rotate the carburetor. Make certain to mount the

throttle arm to the side required by your particular vehicle.

Although preset at the factory, some changes in the

needle setting can occur during shipping and handling.

We suggest the following settings for breaking-in

your engine:

High-Speed Needle: 3

1

/

4

turns out (counterclockwise)

from closed.

Low-Speed Needle: 3 turns out (counterclockwise)

from closed.

When checking the adjustment of the low-speed

needle, it is crucial that the throttle barrel is

closed completely when turning the needle

and that you do not over-tighten the needle.

We suggest using a Dynamite

®

engine-tuning

screwdriver (DYN2775) to make this job easier.

When you feel resistance in the needle,

immediately stop turning and begin turning the

needles counterclockwise, counting the number

of turns from “closed.”

Starting Your Engine For The First Time

The first start of your engine is the most critical time of

the engine’s life, dictating how well it will perform. After

installing the engine in your model and inserting the glow

plug, turn on your radio system and attach a glow igniter

to the glow plug.

When using a recoil starter, never pull the rope

out to its full length, as doing so may cause

damage and recoil starter failure. Quick, short

pulls of the recoil starter are the best technique

to use. Never extend the starter rope more than

12 inches.

Should the pull-starter be extremely difficult to pull (will

not extend out of the assembly), the engine may be flood-

ed (hydro-locked). Excess fuel between the cylinder head

and piston will not allow the piston to travel through its

full range of compression, effectively “locking up” the

engine. Should this occur, immediately remove the glow

igniter from the plug. Using a quality glow plug wrench

(DYN2510), remove the glow plug and turn the model

upside down. Give the recoil starter a few short pulls to

clear out the fuel, re-install the glow plug and start again.

We recommend using an electric starter or starter box for

the initial starts, even with a pull-start equipped engine.

You may need to “blip” the throttle on the transmitter

(applying throttle on/off) while trying to start the engine,

as new engines are more difficult to start due to the tight

piston/cylinder fit. Never start an engine above

1

⁄

4

throttle. Immediate damage to your engine

can and will occur.

When the engine starts, the exhaust should emit

lots of blue/white smoke, indicating that the engine is

excessively rich (a good thing during break-in). During

the first tank of fuel, you may wish to set a higher than

normal idle speed and/or leave the glow plug igniter

attached in order to keep the engine from stalling. Drive

your vehicle around while “blipping” the throttle and

avoid operating the engine at full throttle for more than

2–3 seconds at a time. Consume the entire first two tanks

of fuel in this manner.

After the first two tanks of fuel, begin leaning out the

high-speed needle valve 1/8 turn at a time. It generally

takes about 5 or 6 tanks of fuel before you’d want to start

tuning for “maximum” power. Do not skip this

process of breaking-in a new or rebuilt engine.

Should you choose not to follow these procedures,

you risk damaging your engine in the first tank

of fuel.

Your patience during these procedures will be rewarded

by an engine that performs reliably and to its maximum

power potential. First run attempts can be more frustrating

than with other (less powerful) sport engines, so take

your time—it will be worth the wait.

Glow plug failure is a common occurrence when breaking

in a new engine. To test your plug, let the engine idle at

a properly adjusted low-speed needle setting with the

glow igniter attached. Then, remove the igniter. If you hear

no appreciable change in engine rpm, then the plug is

still good. If the engine loads up and the rpm’s decrease,

it’s time to replace the glow plug.

Setting the Needle Valves

When tuning the needle valves for maximum

performance, adjust them is small increments,

1

⁄

8

turn

at a time.

An engine should not be run too lean; doing so severely

shortens the life of the engine. When an engine is set too

lean, it will run very strong at first but will soon begin to

sag and hesitate or stall when accelerating.

The best way to tune an engine is by using an infrared

temperature gauge, but you can also use water to check

the head temperature. (Refer to “Tuning the High-Speed

Needle” below.)

Tuning the High-Speed Needle

To obtain the correct high-speed needle setting, start the

engine and drive your vehicle around for a minute or two,

applying full throttle for periods of 5 seconds or more.

Place a drop of water on the cylinder head. If the water

sizzles away (evaporates immediately) the needle setting

is too lean. A correct needle setting will result in the water

evaporating after 3-5 seconds. If the water does not

evaporate, chances are good that the needle setting is too

rich. Lean the needle 1/8 of a turn and run the engine

again, adjusting the needle setting to get the desired

evaporation time. Check the temperature each time

you change the needle mixture. Do not let the

engine overheat, as this will damage the engine.

Tuning the Low-Speed Needle

The low-speed needle (also referred to as the idle mixture

or idle needle) should be set after you’re satisfied with

the high-speed needle setting. After achieving the proper

operating temperature, reduce the engine throttle to idle

and pinch the fuel line for 3-5 seconds with your fingers

close to the carb fuel inlet nipple. If the engine dies

immediately, the low-speed needle is set too lean.

If the rpm’s increase dramatically, the setting is too rich.

The ideal setting results in the rpm’s increasing just

a slight amount after pinching the fuel line.

MACH .15RE

Owner’s Manual

Leaner

Low-Speed

Needle Valve

High-Speed Needle Valve

Idle Stop Adjustment

Fuel Inlet

(Adjustable)

Faster Idle

Slower Idle

Leaner

C

M

Y

CM

MY

CY

CMY

K

Page 1.pdf 12/8/04 2:56:15 AM

Page 1.pdf 12/8/04 2:56:15 AM