Losi LOSB0101 User Manual

Page 13

24

25

®

®

Tuning the Rear End of the Speed-T

Shock Location: Moving the shocks out on the arm will result

in less forward traction and let the Speed-T make more of an arc

through the exit of the turn. In general, when changing shock

locations on the arm, it will be necessary to go down one spring

rate when moving out on the arm.

Static Camber: Having the same definition as for the front end

and measured in the same fashion, rear camber can also be a

critical tuning feature. Testing has shown that running a small

amount of negative camber (.5-1 degree) is best. Increasing

negative rear camber (in the range of 1.5-3 degrees) will

increase stability and traction in corners, but decrease high

speed stability. Decreasing rear camber (in the range of 0-1.5

degrees) will decrease stability and traction in corners, but will

increase high speed stability.

Inboard Camber Location: The Speed-T has multiple rear

camber locations. Using a longer camber link will improve

stability and traction (grip). Using a shorter camber link will

increase steering while decreasing rear grip. Running the

camber link in the inside position on the shock tower will give

your Speed-T more steering entering the turn as it will let

the Speed-T set over the rear tire and give you more forward

traction exiting the turn. As you move the camber link towards

the outside of the Speed-T, you will gain less initial steering,

however, you will gain more steering as the Speed-T exits the

turn. The Speed-T now has the capabilities of a lower row of

holes in the rear shock tower for the inner camber link location.

The lower hole gives the Speed-T more camber gain (more

angle relative to arm = more camber gain). This can be helpful

when tracks get bumpy and rutted to help the rear end of the

Speed-T go through the bumps easier due to the increased

camber gain of the tires.

Outboard Camber Location: Running the camber link in the

inside position on the hub will generate more rotation entering

a turn, but decrease steering on exit. Running the camber link

in the furthest outer position on the hub will generate more

stability entering a turn and increase steering on exit.

Toe-In: Having the same definition as for the front end, the toe-

in can be adjusted on the Speed-T with the rear hubs. The stock

toe-in is 3 degrees of inboard per side and 0 degrees in the hub.

Increasing rear toe-in will increase forward traction and initial

steering, but reduce straightaway speed. Decreasing rear toe-in

will decrease forward traction and “free-up” the Speed-T. Less

toe-in can be used to gain top speed.

Anti/Pro-Squat: Increasing anti-squat is generated by raising

the front of the pivot block, relative to the rear of the pivot.

This will increase initial steering and forward traction. You can

increase anti-squat in 1 degree increments by using two .030"

washers between the front of the pivot plate and pivot block.

Pro-squat is generated by raising the rear of the pivot relative to

the front. This will decrease forward traction and initial steering,

but provide more on-power steering on high traction surfaces.

Pro-squat will also help the Speed-T from pulling wheelies on

high bite surfaces. Also available is an aftermarket part that is a

0 degree rear pivot block (LOSA2112), if pro-squat is desired it is

best to start with this option.

Tuning the Chassis of the Speed-T

Slipper Adjustment: This should be done after the locker-diff

is properly adjusted (see page 25). After fully tightening the

adjustment nut (so the coils of the spring just touch) loosen the

slipper adjustment nut 2 1/4 turns. This will be a good starting

point for your slipper settings. Too loose and the vehicle will not

have acceleration, and too tight will pop wheelies but can result

in a broken locker-diff gear.

Ride Height: This is the height of the chassis in relation to the

surface. It is an adjustment that affects the way your Speed-T

jumps, turns and goes through bumps. To check the ride

height, drop one end (front or rear) of the Speed-T from about

a 5-6 inch height onto a flat surface. Once the Speed-T settles

into a position, check the height of that end of the Speed-T in

relationship to the surface. To raise the ride height, lower the

shock adjuster nuts on the shock evenly on the end (front or

rear) of the Speed-T that you are working on. To lower the ride

height, raise the shock adjuster nuts. Both left and right nuts

should be adjusted evenly.

You should start with the rear ride height where the Speed-T

comes to a rest at a height where the dog bones are slightly

below level with the surface. The front ride height should be

set so that the bottom of the chassis is level with the surface.

Occasionally, you may want to raise the front ride height to

get a little quicker steering reaction but be careful as this can

also make the Speed-T easily flip over. Every driver likes a little

different feel so you should try small ride height adjustments

to obtain the feel you like. This should be one of the last

adjustments after everything else has been dialed in (tuned).

Do not use ride height adjustment as a substitute for a change

in spring rate. If your Speed-T needs a softer or firmer spring,

change the spring. Do not think that simply moving the shock

nuts will change the stiffness of the spring; it will not.

Battery Position: This is a critical adjustment that is often

overlooked but can be very useful. Start by running the battery

spaced in the middle (standard setup with 6-cell battery pack).

Moving the battery back can improve rear traction on slippery

surfaces and steering response. Moving the battery back too

far can cause the rear end to swing through turns on some

tracks and “dump” the rear end causing instability issues. This is

a result of having the weight too far back. The Speed-T comes

equipped with two foam battery spacers to split the difference

when adjusting the battery position, hence offering a middle

position when either extreme is inadequate.

Camber Rise Relationship: The Speed-T setup out of the box

comes with less front camber gain than the rear camber gain.

The reason for this is that less front camber lets the front end

drive flatter and makes the Speed-T more stable. By having

more camber gain in the rear, the Speed-T has more rear

traction, this helps the rear tires accelerate through the bumps

and ruts.

Wheels and Tires

The tires come pre-mounted with the vehicle and should be

checked to make certain they stay glued to the wheels. The

wheel spinning speeds this vehicle is capable of tend to pull the

rubber tire away from the rim. When a tire or tires come loose

from the rim you will notice the vehicle is hard to control.

Tip the vehicle on its side and using both hands to hold one

wheel at a time, use your thumb to press the tire away from

the rim. If you see a tire pull away for the rim use Losi Tire Glue

(LOSA7880 thick or LOSA7881 thin) to re-glue. It only takes a

small drop of glue generally. Be careful this is CA-type glue and

you do not want to glue your fingers to the wheel and tire.

Use safety goggles when gluing tires.

Check the mounting of the tire periodically to ensure proper

performance and handling.

Steering Assembly: Occasionally, check the steering assembly

and you may notice increased looseness. There are several

components which will wear out from use: tie rod ends

(part LOSA6074), the servo saver (part LOSA1610), the bell

crank bushings (part LOSA1620), and the Drag link ball ends

(LOSA6074). You can easily replace these components to restore

factory specifications.

Note: The bell crank bushings may be replaced with

ball bearings (part LOSA6912).

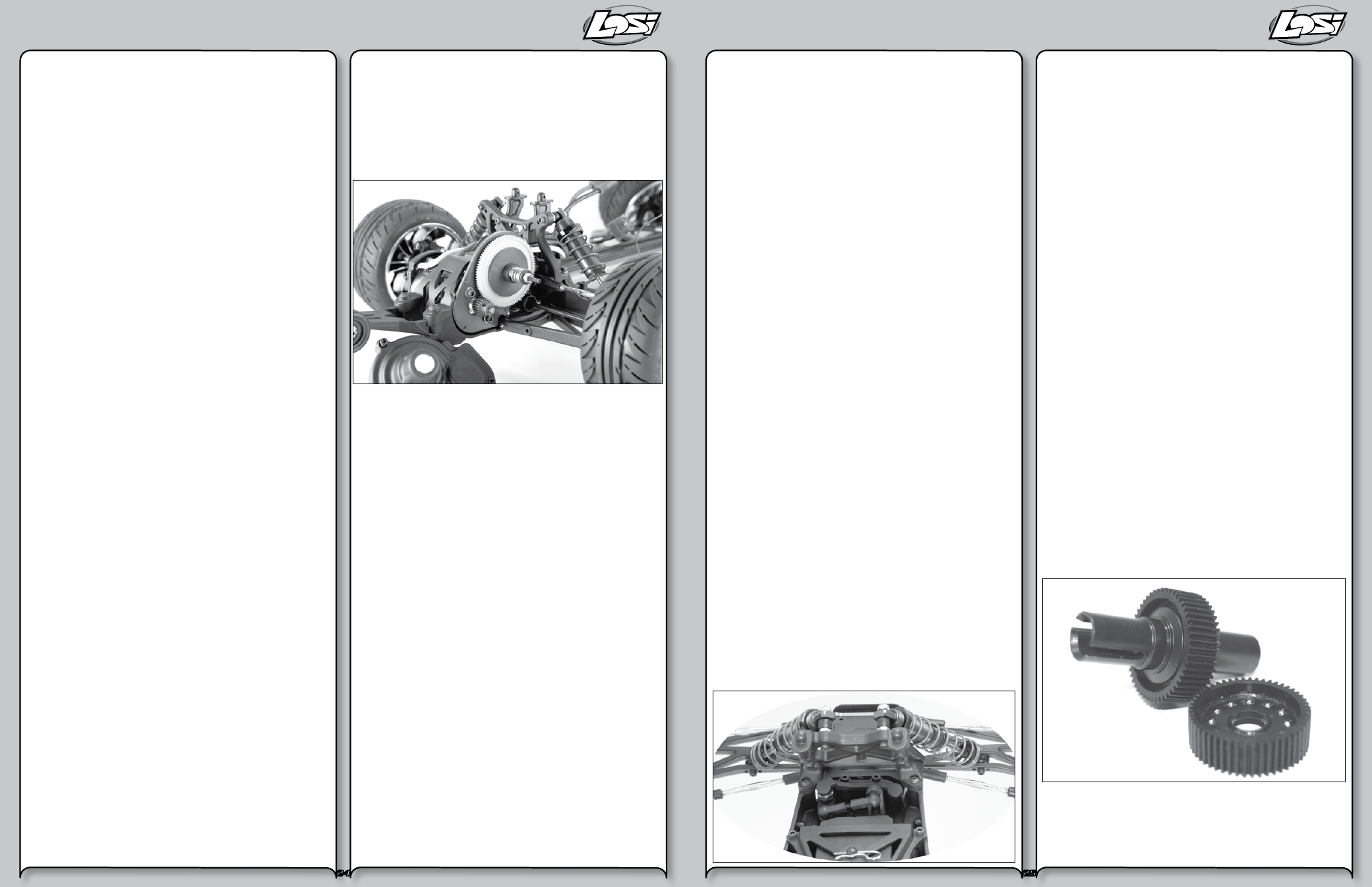

Locker Differential (Spool)

(Standard equipment for Speed-T)

The Speed-T makes use of a locker rear differential to equally

deliver the power to the rear wheels.

The Locker differential will operate with minimal maintenance.

If you need to take it apart for any maintenance, use the

exploded view to reassemble. The differential adjustment screw

should be tightened quite tightly using a blade screwdriver

(90 to 100 inch pounds). After you reassemble the vehicle hold

one wheel and attempt to turn the other, it should take a lot of

force to make it turn if any. If the wheels turn you can remove

the rear dog bone and expose the adjusting screw. Tighten the

screw another 1/8th turn and try again.

Note: If you are running the Speed-T in Off-Road

conditions, you may want to use the optional

standard ball differential. You can rebuild the Locker

differential into the standard differential by removing

and disassembling the transmission. Take apart the

Locker Differential and remove the two thin pads in

the diff gear. You will see there are 12 holes exposed

after doing this. Using Losi diff balls (LOSA6951) insert

them carefully into these holes. Use a small amount of

Losi Diff Grease (LOSA3065) during reassembly. Then

after reassembly of the transmission and installation

into the vehicle. Please refer to “Standard Ball

Differential Adjustment” for further instructions.

Suspension: Periodically inspect the model for signs of damage

such as bent or dirty suspension pins, bent turnbuckles, loose

screws and any signs of stress or bending. Replace components

as needed.

Outdrives: Inspect both outdrive halves for signs of wear. After

extended use they will develop a wear mark or notch in them.

It requires that you remove the transmission, then disassemble

the locker differential. The replacement outdrives are part

number LOSA3073.

Completed Locker Diff/Spool

Optional Differential Setup with

Steel balls and grease ready for conversion