Engine installation – Losi LOSA0881 User Manual

Page 35

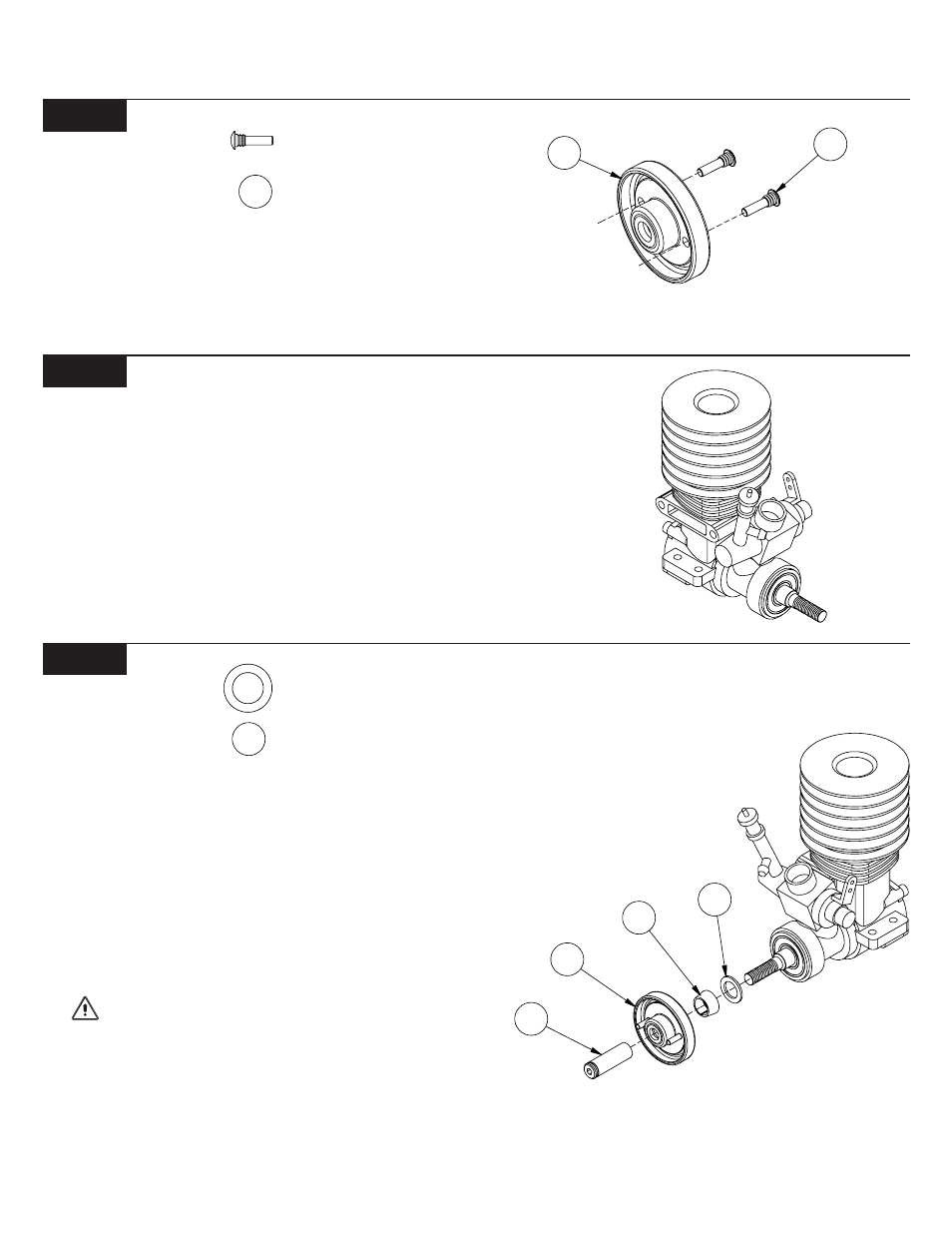

ENGINE INSTALLATION

3 2

Figure 73

Figure 71

Step 1. Thread a clutch pin/screw (151) into each of the small holes in

the flywheel (152) and tighten with a .050" Allen wrench. The screws

should be inserted from the rear as shown.

Tip: A small amount of thread-lock compound should be used on

the threads of the clutch pins.

Step 2. Remove any hardware that came installed on the crankshaft of

your engine. This includes all nuts, washers, and prop hubs.

*NOTE: If your engine did not come with a glow plug you will need

to purchase one. Use a glow plug wrench, or a 5/16" nut driver to

install the glow plug into the head of the engine. Most glow plugs

come with a brass washer. Make sure that this washer is placed on

the glow plug before it is installed.

Step 3. Slide a flywheel shim (153) over the crankshaft, and against

the front bearing on the engine. Slide the flywheel collet (154), large

side first, over the crankshaft and next to the shim (153).

Tip: There are two shims included in the kit. If the flywheel inter-

feres with the case of the engine, add a second shim. If after the

engine is installed, the gears don't line up properly, a second shim

can be added to help correct the alignment.

Step 4. Slide the flywheel (152), pins out, over the crankshaft. The

flywheel (152) should be seated over the collet (154). Thread the

clutch nut (155) onto the crankshaft and tighten it using a 3/32"

Allen wrench.

IMPORTANT NOTE: The clutch nut should be very tight.

Hold the flywheel with a rag in order to get a good grip while tighten-

ing the clutch nut. There are special tools available for inserting in the

head of the engine to keep it from turning over while tightening the

clutch nut. Other than these special tools, nothing should ever be

inserted in the head of the engine to keep it from turning over!

Figure 71

Figure 72

Figure 73

151

153

154

152

155

153

Figure 72

151

152