Bag c (continued) – Losi LOSA0881 User Manual

Page 17

BAG C (Continued)

1 4

Figure 33

Figure 33

Figure 34

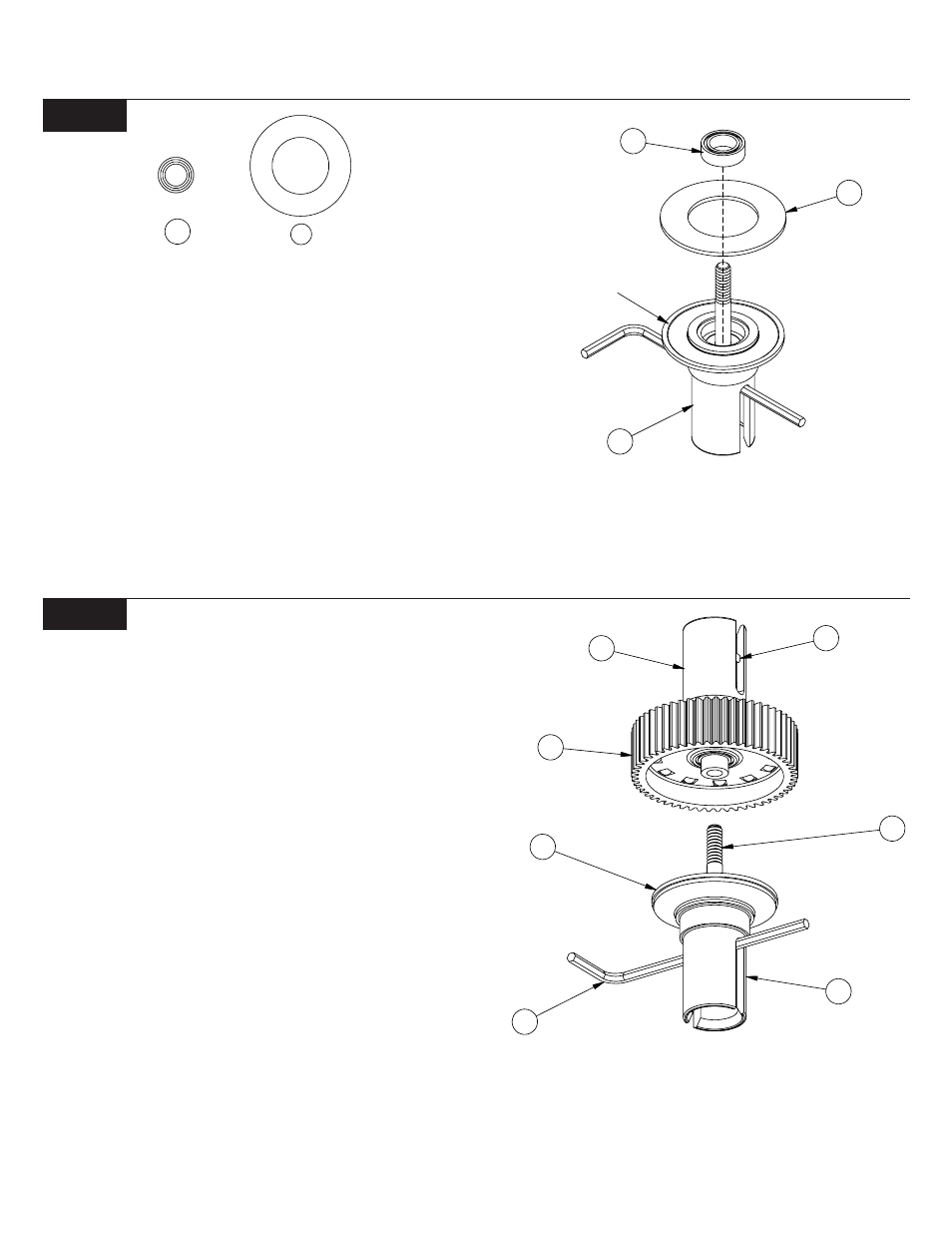

Step 15. Locate the smallest of the Allen wrenches (59) and place it

through the slot in the outdrive/diff half (66) containing the diff screw

(67). Slide the wrench all the way against the screw (67). By handling

the outdrive/diff half (66) with the wrench

inserted, the diff screw (67) will be held in place while finishing as-

sembly of the differential.

Step 16. Insert a 5mm x 8mm bearing (63) into the female outdrive/diff

half (66). Make sure that the bearing (63) is pushed all the way into

the outdrive (66).

Step 17. Apply a small amount of diff grease (clear) (62) all the way

around the face of the outside ridge of the outdrive/diff half (66).

Attach a diff washer (61) to the outdrive (66) by centering the hole in

the washer (61) over the raised center of the outdrive (66).

*NOTE: Only a small amount of grease is needed, but be sure to

cover the entire face of the ridge on the outdrive.

Step 18. Apply a fairly heavy coat of clear diff grease (62) to the

exposed side of the diff washer (61).

Step 19. While holding the outdrive/diff half (66) with the Allen wrench

inserted, carefully place the two outdrive/diff halves (60)(66) together.

Step 20. Make sure that the slot in the diff screw (67) is lined up with

the slot in the outdrive/diff half (66) and that the Allen wrench is

inserted in the slot in the diff screw (67).

Step 21. Hold the diff so that the outdrive/diff half (60) with the diff

nut carrier (57) is pointing up. Slowly turn the top diff half clockwise

to thread the diff screw (67) into the 4-40 mini locknut (7) in the diff

nut carrier (57). Thread the two halves together until the screw just

starts to snug up.

*NOTE: If the screw will not thread into the nut, make sure that

the diff nut carrier is pushed all the way into the outdrive/diff half.

Tip: When tightening the diff, tighten the screw a little and then

“work” the diff a little. Then tighten the diff a little more and

“work” the diff again. Continue this until the diff is tight. This

will ensure proper seating of all the parts in the diff

assembly.

Step 22. Tighten the diff until the gear (64) cannot be turned while

both of the outdrives (60)(66) are being held. Final diff

adjustment should be made after completion of the car.

Figure 34

63

61

61

63

66

GREASE

60

64

67

59

66

57

61