Assembly options, Assembly procedure – Elecraft AT1 41 dB Step Attenuator User Manual

Page 2

2

Reference. Designator

Description

Qty

Part

Number

R8 18

Ω (180) 1W Resistor

1

E500259

R10, R12

150

Ω 2W Resistor

2

E500260

R11 39

Ω (390) 2W Resistor

1

E500261

R13, R15

100

Ω 2W Resistor

2

E500262

R14 68

Ω 2W Resistor

1

E500078

R16, R18

62

Ω 2W Resistor

2

E500167

R17 240

Ω 2W Resistor

1

E500263

SW1, SW2, SW3, SW4, SW5, SW6

Slide Switch

6

E640032

Misc.

Wooden Spacer (see Figure 2 on page 3).

1

E980131

Misc. Rubber

Foot

4

E700024

Assembly Options

The AT1 is designed to operate as a stand-alone unit without an enclosure. Options are provided in case you want to build the

unit into an enclosure or existing equipment:

1. Your AT1 is provided with BNC connectors that mount parallel to the board. Normally these connectors will be

mounted on the top (silk screened) side of the board so that the board rests flat on the supplied rubber feet attached

to the bottom. However, if you are building the unit to place in an enclosure of your choice, you may elect to mount

the BNC connectors on the bottom of the board so the switches can be flush with the enclosure cover. Also, you may

purchase right-angle BNC connectors that may be mounted either on the top or the bottom of the board. Suitable

connectors are available from Digi-Key

®

(

www.digikey.com

, part number A32246-ND) or Mouser Electronics

®

(

www.mouser.com

, part number 571-2272226).

2. Four holes are provided in the board that you may use with your own #4 hardware and spacers as needed to mount

the unit instead of using the rubber feet.

Assembly Procedure

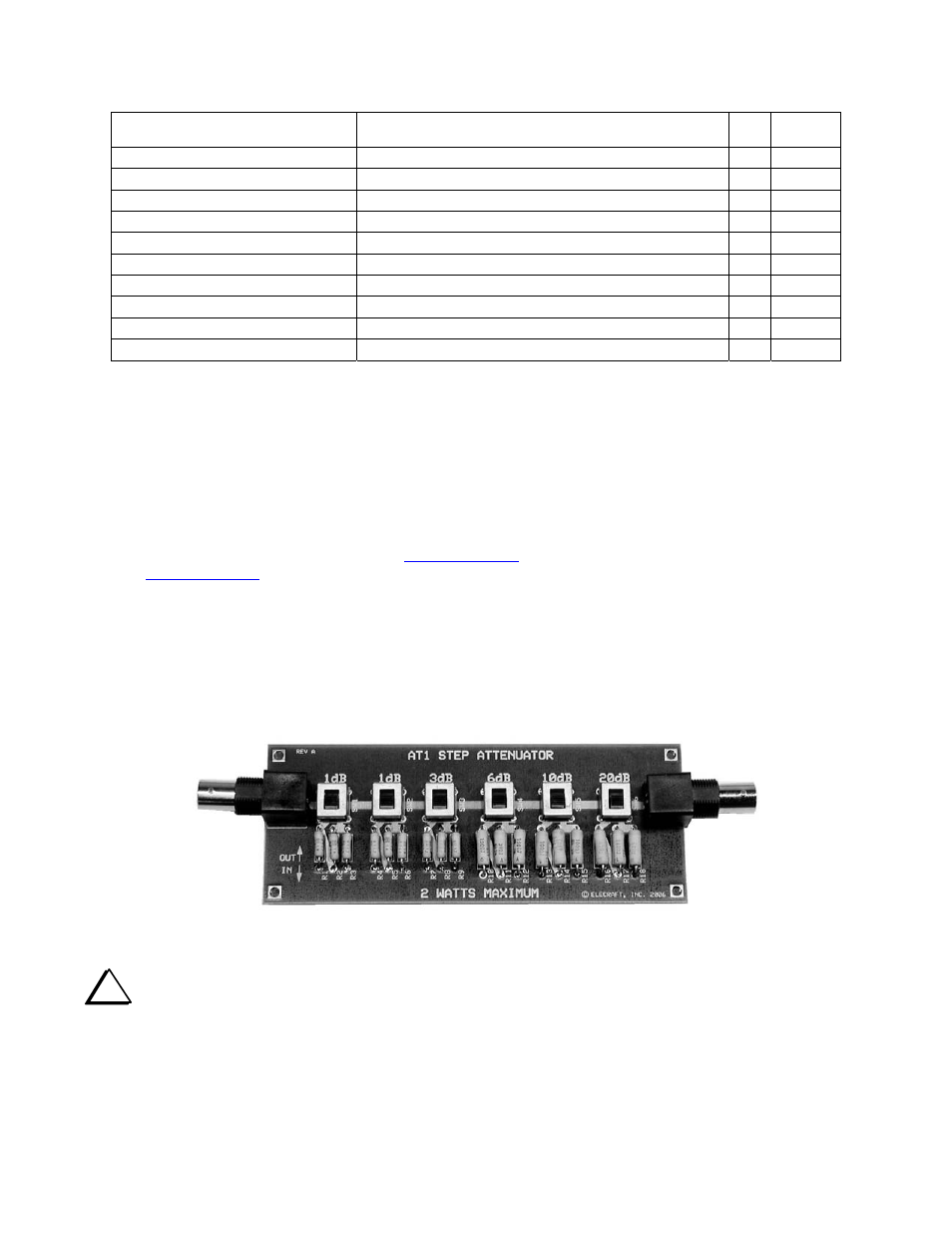

The finished Attenuator is shown in Figure 1. We recommend you follow the assembly procedure below, and refer to this

figure as needed.

Figure 1. Assembled AT1 Step Attenuator.

i

Use adequate ventilation when soldering; avoid inhaling smoke or fumes. Always wash your hands after

handling solder, as lead residue is highly toxic.

When applying solder, use the minimum amount required to surround the component lead and make good contact with its

printed-circuit pad. You don't need a "fillet" (build-up) of solder. This will avoid unwanted solder bridges and any need to

clean the PC boards.

The solder must flow onto both the component lead and its PC board pad. To ensure that both will be heated at the same time,

the tip of the iron should contact both the component lead and the PC board pad before solder is applied.