Troubleshooting problem cause solution – Craftsman 315.228310 User Manual

Page 43

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

1

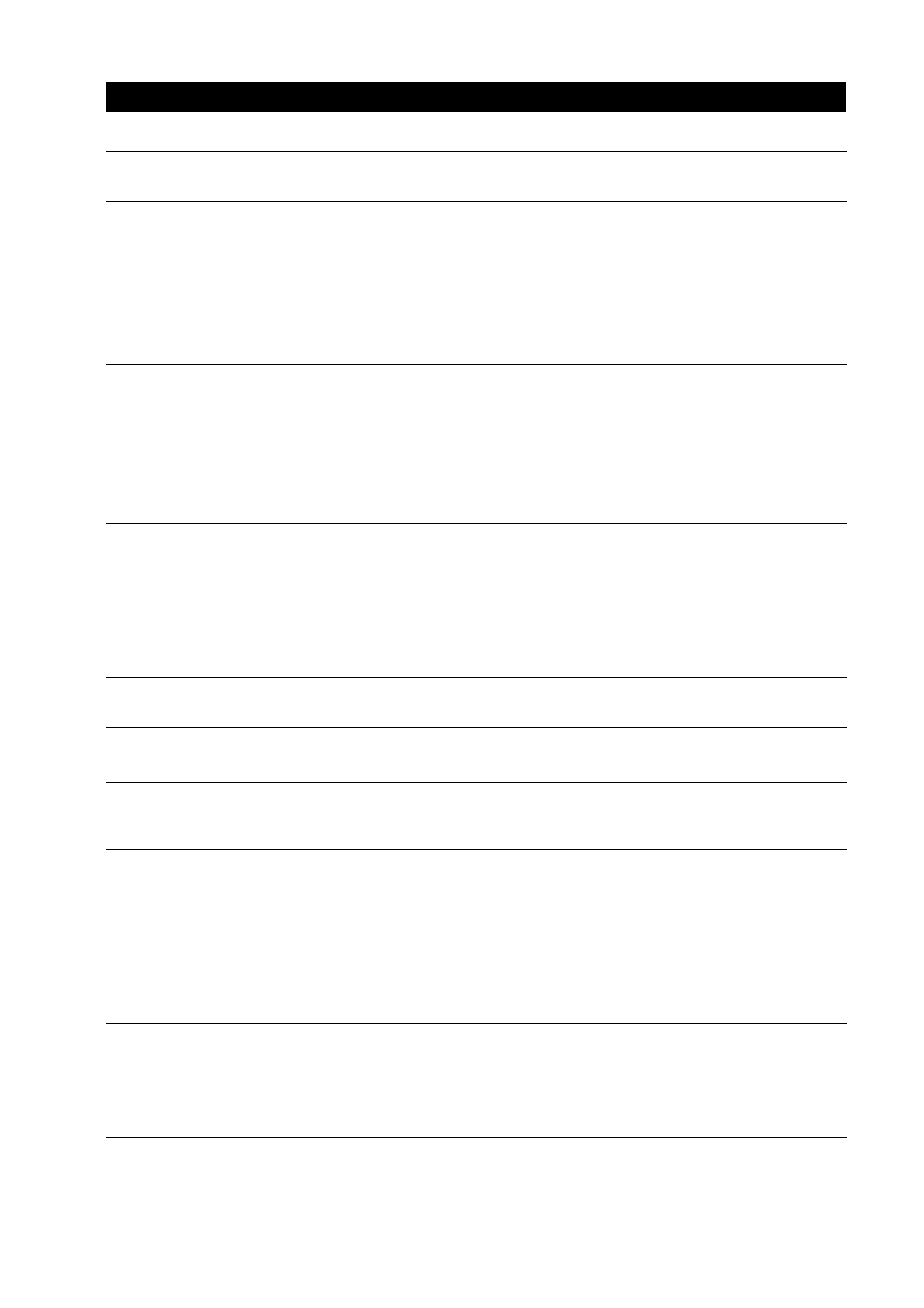

TROUBLESHOOTING

PROBLEM

CAUSE

SOLUTION

Fuses or circuit breakers open

frequently.

1. Motor is overloaded.

2. Fuses or circuit breakers are

wrong size or defective.

1. Feed work more slowly.

2. Replace fuses or circuit break

ers.

3. Dull blade.

3. Replace the blade.

4. Start switch is defective.

4. Have the switch replaced.

Saw vibrates excessively.

1. Blade is warped.

1. Replace the blade.

2. Belt is damaged.

2. Replace the belt.

3. Saw is not mounted securely.

3. Tighten all hardware.

4. Work surface is uneven.

4. Reposition on a flat surface. Ad

just the leveling feet on legs.

Start switch does not operate.

1. Switch contacts are burned out.

1. Have the switch replaced and re

quest a voltage check from the

power company.

2. Capacitor is defective

2. Have the capacitor replaced.

3. Connections are loose or dam

aged.

3. Have the wiring checked and re

paired.

Handwheels are hard to turn.

1. Sawdust has collected on the

mechanism inside saw.

1. Clean and lubricate the mecha

nism.

Blade does not lower when turning

height handwheel.

1. Blade lock handle is not fully

released.

1. Fully release the blade lock

handle.

Mitergage does not move smoothly.

1. Miter gage assembly is dirty or

sticky.

1. Release the miter gage knob and

wax the miter gage base and

sides.

Cut binds, bums or stalls motor when

ripping.

1. Blade or teeth are dull.

2. Blade is heeling.

1. Sharpen or replace the blade.

2. See Heeling the Sawblade in the

Adjustments section.

3. Board is warped.

3. Replace the board.

4. Rip fence does not parallel blade.

4. See Aligning die Rip Fence in the

Assemb/y section.

Saw blade does not cut true at 90' or

45* positions.

1. Indicators are not properly ad

justed.

2. Positive stops inside base are

not accurate.

1. See Setting the Bevel Stops and

Indicator in the Adjustments sec

tion,

2. See Setting the Bevel Stops and

Indicator in the Adjustments sec

tion.

43

CRRFTSHIIN* TABLE SAW 315.228310