Maintenance, General maintenance, Motor/electrical – Craftsman 315.228310 User Manual

Page 41: Lubrication

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

MAINTENANCE

GENERAL MAINTENANCE

WARNING:

When servicing, use only identical

Craftsman replacement parts. Use of any other

part may create a hazard or cause product

damage.

^ WARNING:

To prevent accidental starting that

couid cause possible serious personal injury,

turn off the saw, remove the switch key, and

unplug the saw before working on the table saw.

■ Remove sawdust from the rails, top surface, and

inside of saw frequently.

■ Clean plastic parts with a soft damp cloth. Do not

use any strong solvents.

WARNING:

Do not at any time let brake fluids,

gasoline, petroleum-based products, penetrating

oils, etc. contact plastic parts. They contain

chemicals that can damage, weaken or destroy

plastic.

■ Periodically clean the table, rails, and rip fence with

gum and pitch remover. Do not allow pitch to

accumulate on the saw.

■ Apply a thin coat of paste wax to the table top so

the wood slides easily while cutting.

■ Regularly check all nuts, bolts, screws, and belts

for tightness and condition. Make sure the throat

plate is in good condition.

MOTOR/ELECTRICAL

■ Frequently vacuum or blow out any sawdust from

the motor.

^ WARNING:

If the power cord is worn, cut, or

damaged in any way, have it replaced immedi

ately by a qualified service technician at a Sears

store or repair center. Failure to do so could

result in serious personal injury.

^ WARNING:

To avoid fire or electrocution,

reassemble electric parts with only identical

Craftsman replacement parts. Reassemble

exactly as originally assembled.

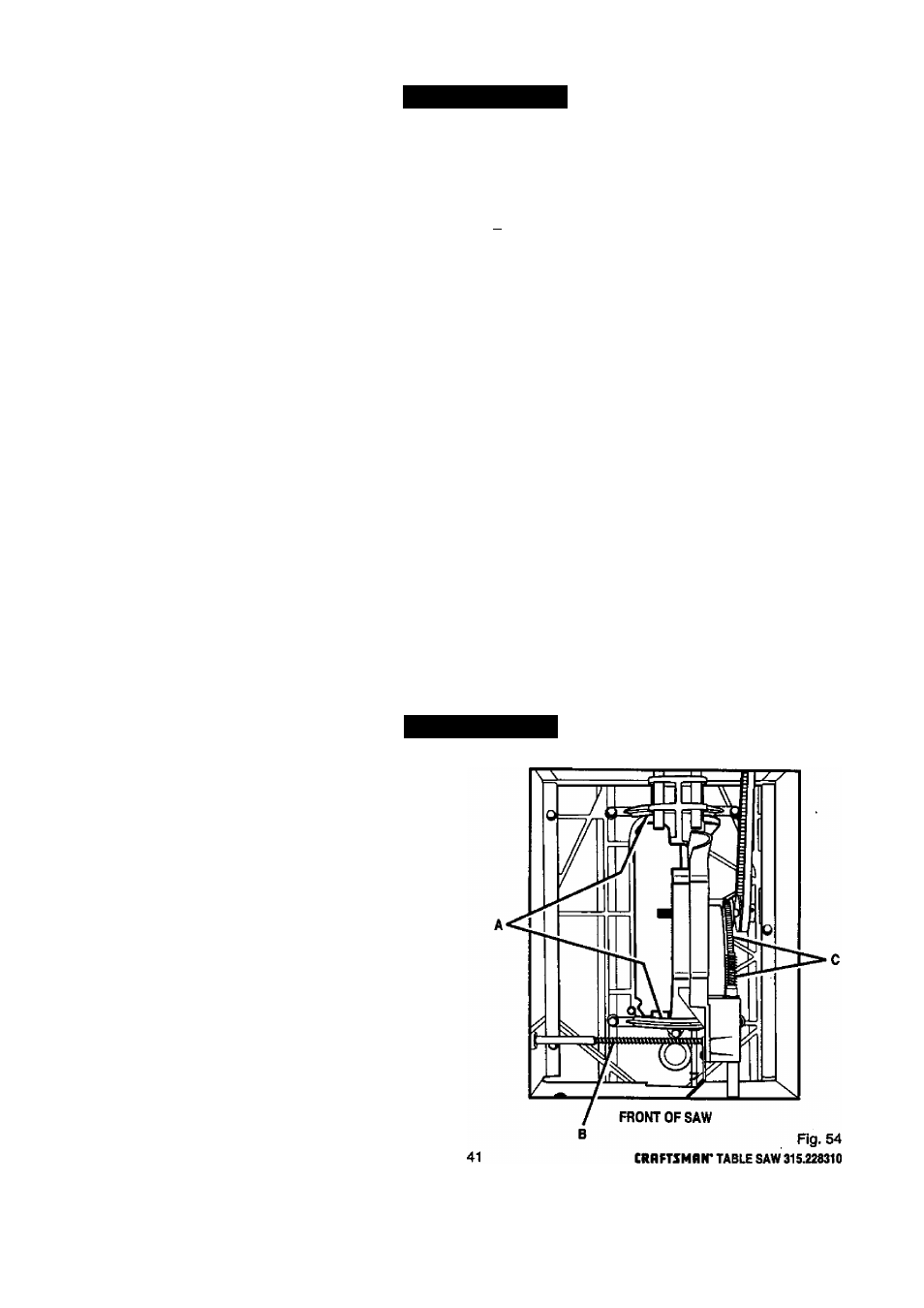

LUBRICATION

This saw has been lubricated at the factory prior to

shipment. After extended use, you should inspect,

clean, and lubricate the areas shown in the drawing.

Clean before lubricating with a solvent recommended

for gum and pitch removal. Lubricate with SAE no. 20

or no. 30 engine oil.

See Figure 54.

■ Table brackets, (a)

■ Bevel handwheel rod threads and knuckle, (b)

■ Height handwheel threads and trunnion, (c)