Assembly, Adjustments, Installing rip scale indicators – Craftsman 315.220381 User Manual

Page 36

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

ASSEMBLY

INSTALLING RIP SCALE INDICATORS

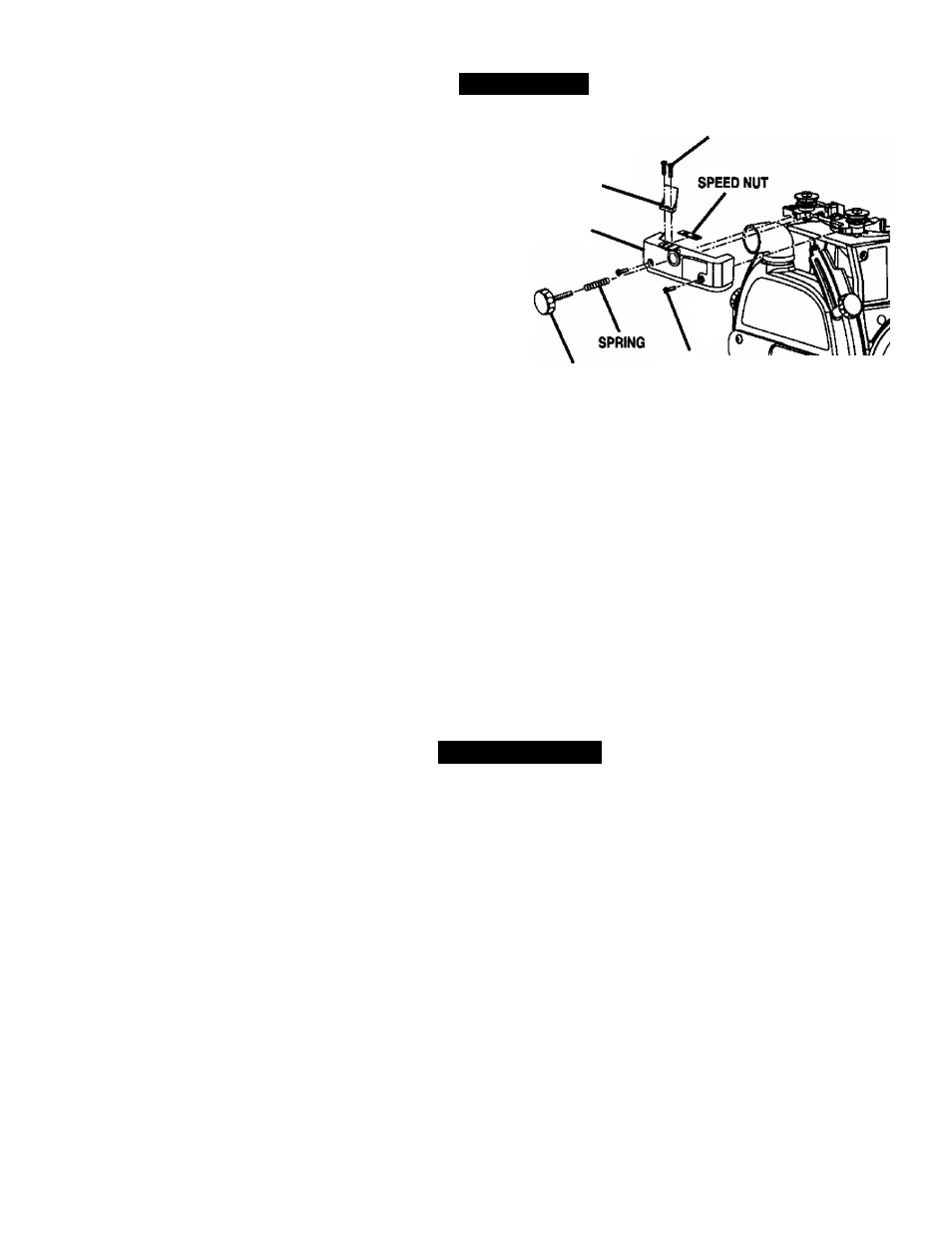

See Figure 28.

The rip scale indicators on the arm show the distance

between the blade and the rip fence with the fence in

the front and rear positions. The upper scale is used

when the fence is positioned directly behind the front

table. The lower scale is used when the fence is at the

extreme rear, directly in front of the column.

The In-Rip Indicator is on the right side of the arm.

The Out-Rip Indicator is on the left side of the arm.

■ Remove the following from a small hardware bag.

2

rip scale indicators

4 screws

2

speed nuts

■ On the left of the radial arm saw, remove the

carriage lock knob and spring.

■ Remove the two carriage cover screws and the

carriage cover.

■ Insert a speed nut inside the carriage cover with the

flat side up. Place the scale indicator on top of the

carriage cover and attach with two screws. Se

curely tighten screws.

■ Replace the carriage cover and tighten the carriage

cover screws.

■ Replace carriage lock knob and spring.

■ Repeat for the right side.

SCREWS

RIP SCALE

INDICATOR

CARRIAGE

COVER

CARRIAGE

LOCK KNOB

SCREWS

Fig. 28

To complete setting up your saw, continue with the

Adjustment procedures. The adjustments should be

checked regularly, depending on usage. Your saw will

provide accurate cuts with fine tolerances as long as

you protect the accuracy with frequent alignment

checks. The radial arm saw can perform a wide range

of high quality cuts.

The final step wiii be connecting the control cut

device. The control cut device offers many benefits.

As it increases operator control, it eliminates the risk

in a cross cut of the saw “climbing" out and over the

workpiece at the operator. Feed control of the blade

as it cuts through the workpiece increases, as does

the accuracy of the cut. The following adjustments

need to be completed before the control cut device is

connected.

ADJUSTMENTS

Your radial arm saw is designed to perform a variety of

complex cuts with fine tolerances. A weekly alignment

check ensures that your saw can perform with precision.

It takes about ten minutes and the results is better

performance and a longer life for your saw.

Perform the checks in the order given. If you miss an

adjustment, go back to the missed adjustment and

repeat all steps from that point fonvard.

CAUTION: Failure to check alignments and

perform the adjustments in the initial set up or on

a frequent basis can result in poor performance or

machine damage.

CRRFTSMDir RADIAL SAW 315.220381

36