Tomei new-concept valve spring features – Tomei Powered VALVE SPRINGS User Manual

Page 7

■TOMEI NEW-CONCEPT Valve Spring Features

(Except L4/6)

● Advanced Oil Tempered Chrome-Silicone Alloy Core

The adopted wire design shows the best design method that suits race applications, ① jump and ② bounce is

reduced so higher rpm limits can be raised. ③ the fatigue limit is raised to increase durability.

● Variable Stage Unequal Pitch Springs

In each spring the design and the set spring rate is set to have a higher natural frequency so to reduce

the chances of resonance. ④ chances of surging is greatly reduced.

● Nitrided

The spring material is surface treated with Nitrogen for improved strength to cope with stress fatigue.

Compatible with high lift camshafts to maximize the life expectancy of these springs.

● Shot Penning

A process that strikes many small steel balls onto the surface of the spring at high speeds is made to enhance

the surface of the spring to raise its fatigue limit. Although it has been carried out earlier during

the manufacturing process.

● Hot Setting

High stress loads that are placed on the springs when hot can cause permanent deformation.

So the added measures were taken to guarantee the problems from “⑤Fading” is prevented.

① JUMP

At high RPM the high lift cams can cause the phenomenon of the valve to leave contact

of the cam lobe "jump" which will cause it to slam back onto the camshafts surface on

return.

② Bounce When the valve returns at such high speeds and landing with a shock on the valve seat

the bounce phenomenon can occur repeatedly.

③ Fatigue

The harsh conditions that the valve springs are subjected to when used with high cam

(Stress)

lifts and high RPM can cause fatigue in the spring and breakages are a common problem

④ Surging

The wire of the valve spring can vibrate which will cause the vibration (resonance) over

(Surge) the entire spring, this phenomenon will have the waves of vibrations going back and forth

in the spring.

⑤ Fading

This phenomenon happens when the spring is subjected to maximum stress loads during

operating conditions.

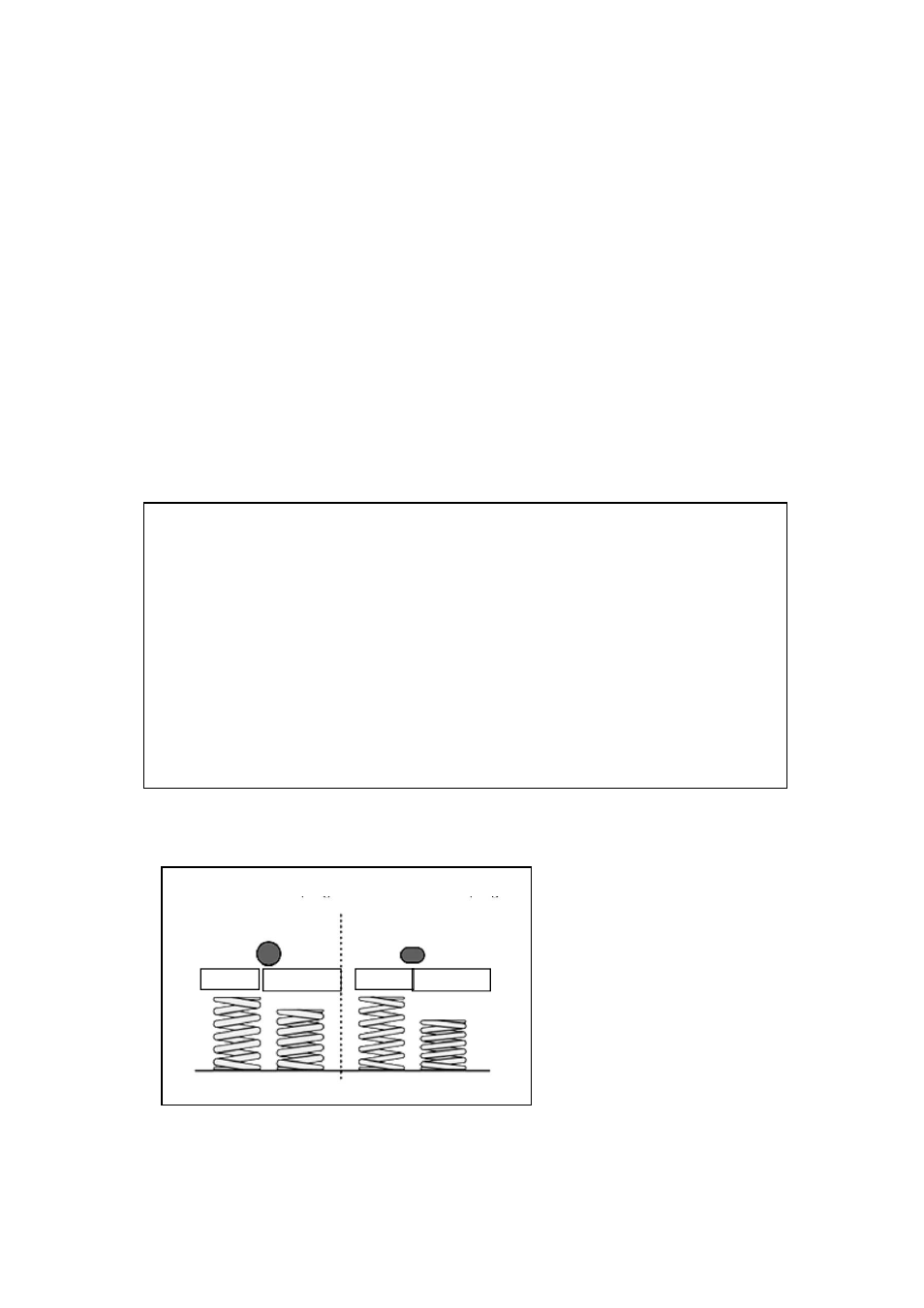

● Oval Core Wire *4G63, VQ35, VR38DETT

The use of the oval shaped spring wire are designed to compress more than the standard design which allows

these engines to run high lift camshafts without comprimise.

Standard Valve Spring

Oval Core Valve Spring

7

Standrd

Compressed

Standrd

Compressed