Taylor-Wharton Auto Fill Laser Pak User Manual

Page 7

7

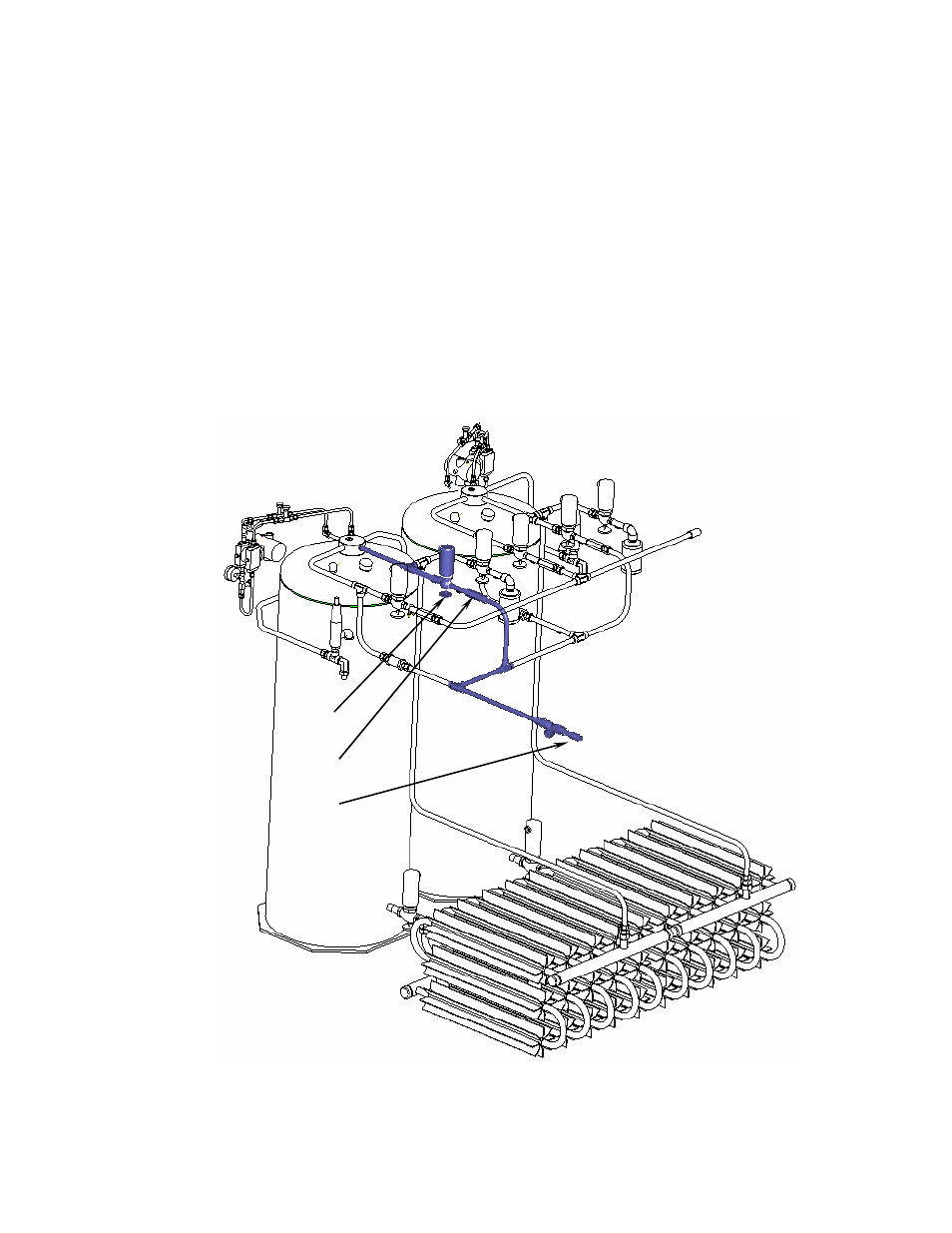

Vent to Bulk Circuits

Before filling occurs, the Auto-Fill Laser Pak recovers high-pressure gas in the vessels by returning it to the

bulk tank. The gas is vented from the top of the vessel through the vent to bulk solenoid valve (V-2). Gas

exits the system through the bulk tank connection (CN-1) and enters the bulk tank through the liquid

withdrawal line. The gas is recondensed as it bubbles through the liquid in the bulk tank. Venting to the bulk

tank occurs until the pressure in the vessels is less than the bulk tank pressure plus 25 psi.

Venting to the bulk tank also occurs during periods of little or no usage. Gas is generated over time due to

heat input to the inner vessel through the supports, piping, and insulation. This gas is recovered by venting it

back to the bulk tank through the same circuit described above. This occurs when the pressure in the vessels

exceeds a user adjustable set point. This is similar to the “economizer” feature found on bulk cryogenic

vessels.

The user can deactivate these features by setting a controller parameter. This is described in the controller

operation section of this manual.

Figure 2: Vent to bulk circuit for vessel A highlighted in blue.

(Frame and wiring omitted from view for clarity.)

CV-2A

CN-1

V-2A