Taylor-Wharton Auto Fill Laser Pak User Manual

Page 12

12

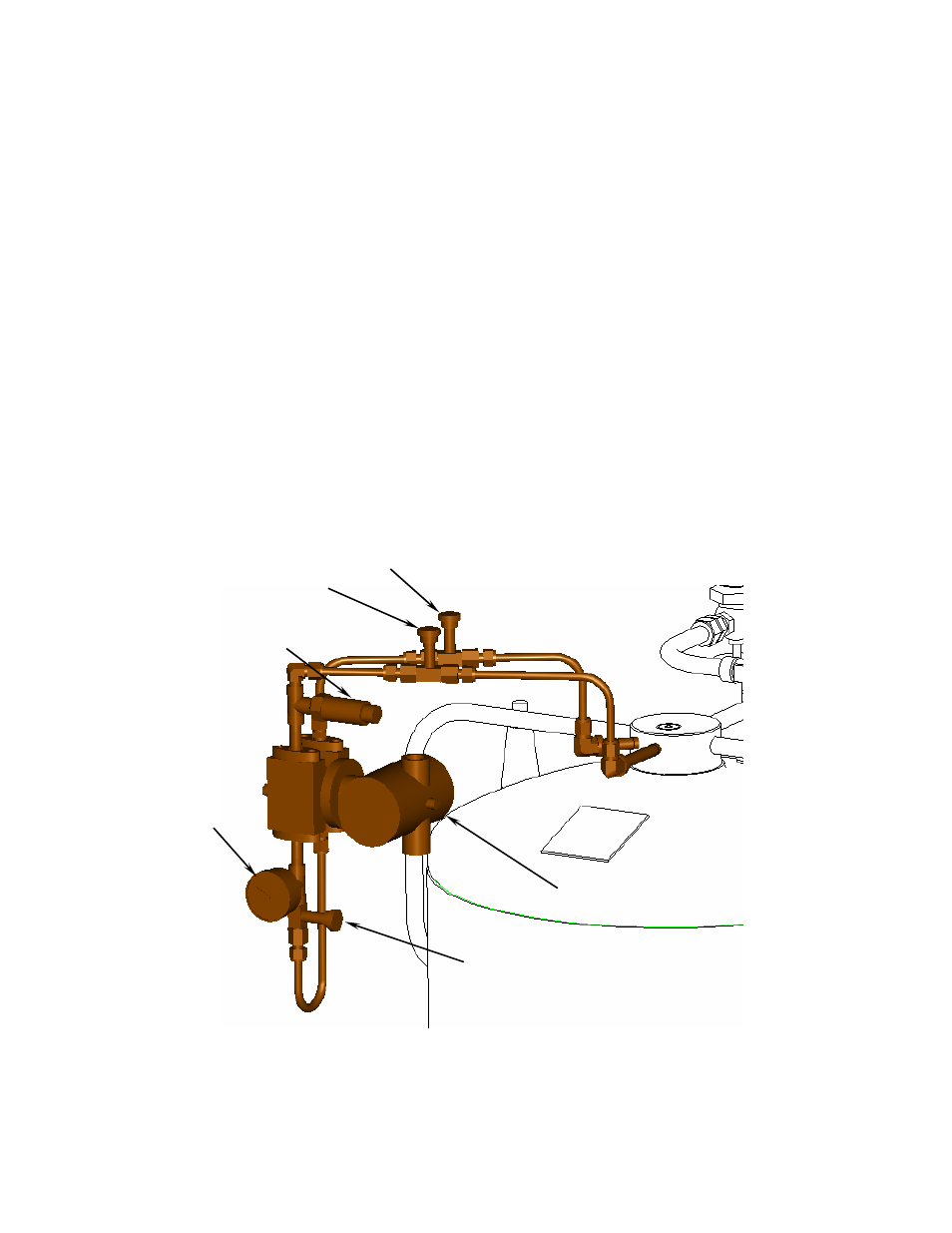

Instrumentation Circuits

The system instrumentation consists of liquid level transmitter, pressure transmitter, pressure gauges, and

isolation valves. The vessel pressure gauges (PI) display the inner container pressure in pounds-per-square-

inch and kilopascals. A pressure gauge is piped to each of the vessels.

The liquid level transmitters (PT-1) measure the liquid level in the vessels. This instrument is a differential

pressure transmitter. Liquid inside the vessel creates slightly greater pressure at the bottom of the vessel than

at the top. The pressure differential increases with increasing liquid content. By measuring this differential

pressure, the liquid level is determined. One of these instruments is supplied for each of the vessels.

Three pressure transmitters monitor pressure in each of the vessels (PT-2) and the bulk tank (PT-3). The bulk

tank pressure transmitter is located inside the Auto-Fill Laser Pak control panel. The controller uses these

inputs to control supply pressure and venting to the bulk tank.

Isolation valves allow the instruments to be replaced without emptying and depressurizing the system.

The vapor phase isolation valve (V-6) isolates the liquid level transmitters, pressure gauges, and pressure

transmitters from the line (low pressure) connected to top of the inner vessel. The liquid phase isolation

valve (V-5) isolates the same instruments from the line (high pressure) connected to the bottom of the

inner vessel. The equalization valve (V-7) is used to equalize the pressure between the high and low-

pressure sides of the liquid level transmitter.

Figure 7: Instrumentation circuit for vessel B highlighted in blue.

(Frame and wiring omitted from view for clarity.)

V-7B

V-6B

V-5B

PI-B

PT-2B

PT-1B