Taylor-Wharton Auto Fill Laser Pak User Manual

Page 6

6

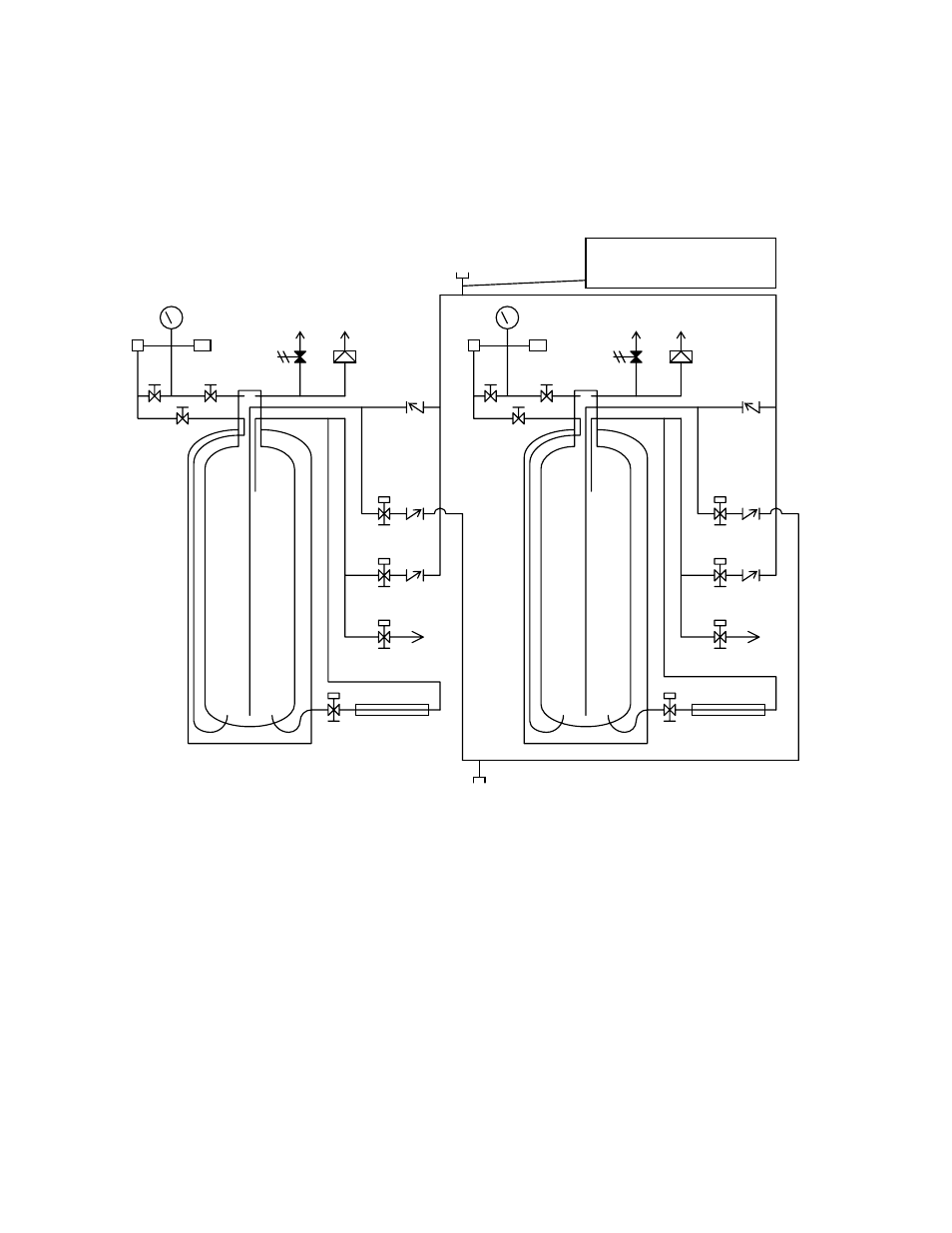

PIPING CIRCUITS

The following paragraphs describe the operation of the piping circuits of the system. The descriptions refer to

the main components of each circuit and are grouped by function. Reference the piping schematic below and

in the general arrangement drawing for the component designations. Round stainless steel tags attached to the

system identify the components. Component tags ending with “A” identify components associated to vessel

A; tags ending with “B” identify components associated to vessel B. These component and circuit

descriptions should be understood before attempting operation.

Legend

CN-1

Bulk Tank Connection

PB

Pressure Builder

CN-2

Vaporizer Connection

V-1

Liquid Use Solenoid Valve

CV-1

Liquid Use Check Valve

V-2

Vent to Bulk Tank Solenoid Valve

CV-2

Vent to Bulk Tank Check Valve

V-3

Vent Solenoid Valve

CV-3

Fill Check Valve

V-4

Pressure Building Solenoid Valve

BD

Rupture Disc

V-5

Liquid Phase Isolation Valve

PI

Vessel Pressure Gauge

V-6

Vapor Phase Isolation Valve

PT-1

Liquid Level Transmitter

V-7

Equalization Valve

PT-2

Vessel Pressure Transmitter

RV-1

ASME Relief Valve

PT-3

Bulk Tank Pressure Transmitter

Figure 1: System Piping Schematic

PB-A

V-4A

V-2A

V-1A CV-1A

CV-2A

CV-3A

BD-A

RV-1A

V-6A

V-5A

V-3A

V-7A

PI-A

PT-2A

PT-1A

PT-1B

PI-B

PT-2B

V-5B

V-7B

V-6B

RV-1B BD-B

CV-3B

CV-1B

V-1B

V-2B CV-2B

V-3B

PB-B

V-4B

CN-2

CN-1

Vessel “B”

Vessel “A”

AF55-0C00 has a

strainer following the

bulk connection