Taylor-Wharton Auto Fill Laser Pak User Manual

Page 13

13

INSTALLATION

Dimension and connection data for the Auto-Fill Laser Pak can be found on the General Arrangement

Drawing in the appendix of this manual. System installation is the responsibility of the customer.

Handling

Employ experienced personnel to move and install the system. Ensure that rigging equipment, if used, has

adequate rated capacity to handle the system weight listed in the specifications. This system must be

shipped and lifted empty.

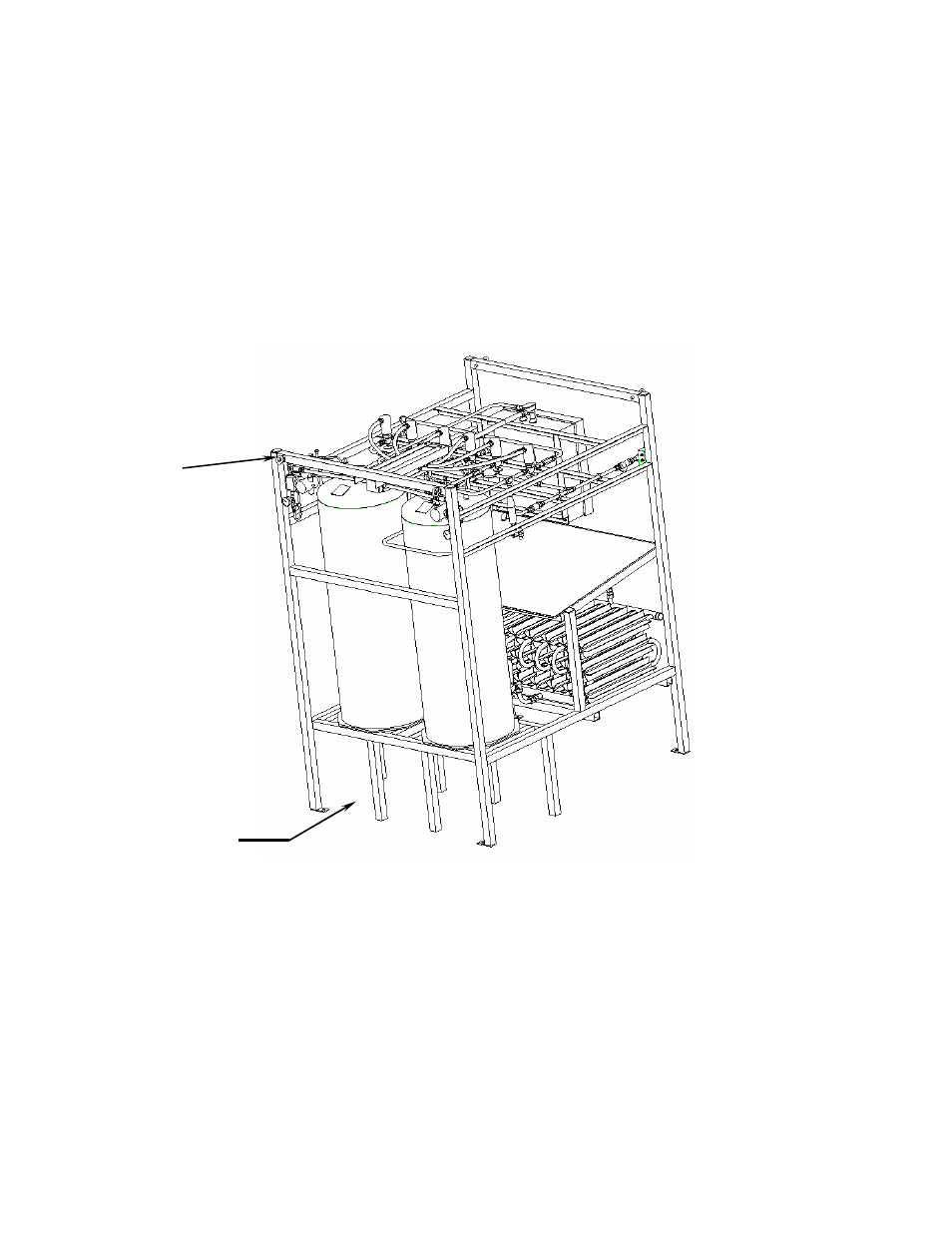

Important: The system may be handled by forklift from the side with the cylinders only. Lifting by forklift

from other sides may cause the system to be unstable and tip. When lifting by crane, use all four lift-eyes.

Figure 8: Handling

Pre-Installation Checks

Before installing the system, inspect it carefully for possible shipping damage. Report any damage to the

carrier and the factory. In addition, check system pressure as follows:

The system is shipped pressurized with nitrogen gas at 20 psig (1.38 bar/138 kPa). Record the "as received"

pressure for both vessels.

System pressure may change due to temperature variations, accidental opening of valves, or packing leaks. If

a positive pressure is not indicated on the vessel pressure gauges (PI) and no repairable leaks are found,

contact the factory. This pressure reading is essential to complete a “first fill” warranty claim.

Lift-Eye

Forklift on

this side only