Taylor-Wharton Auto Fill Laser Pak User Manual

Page 26

26

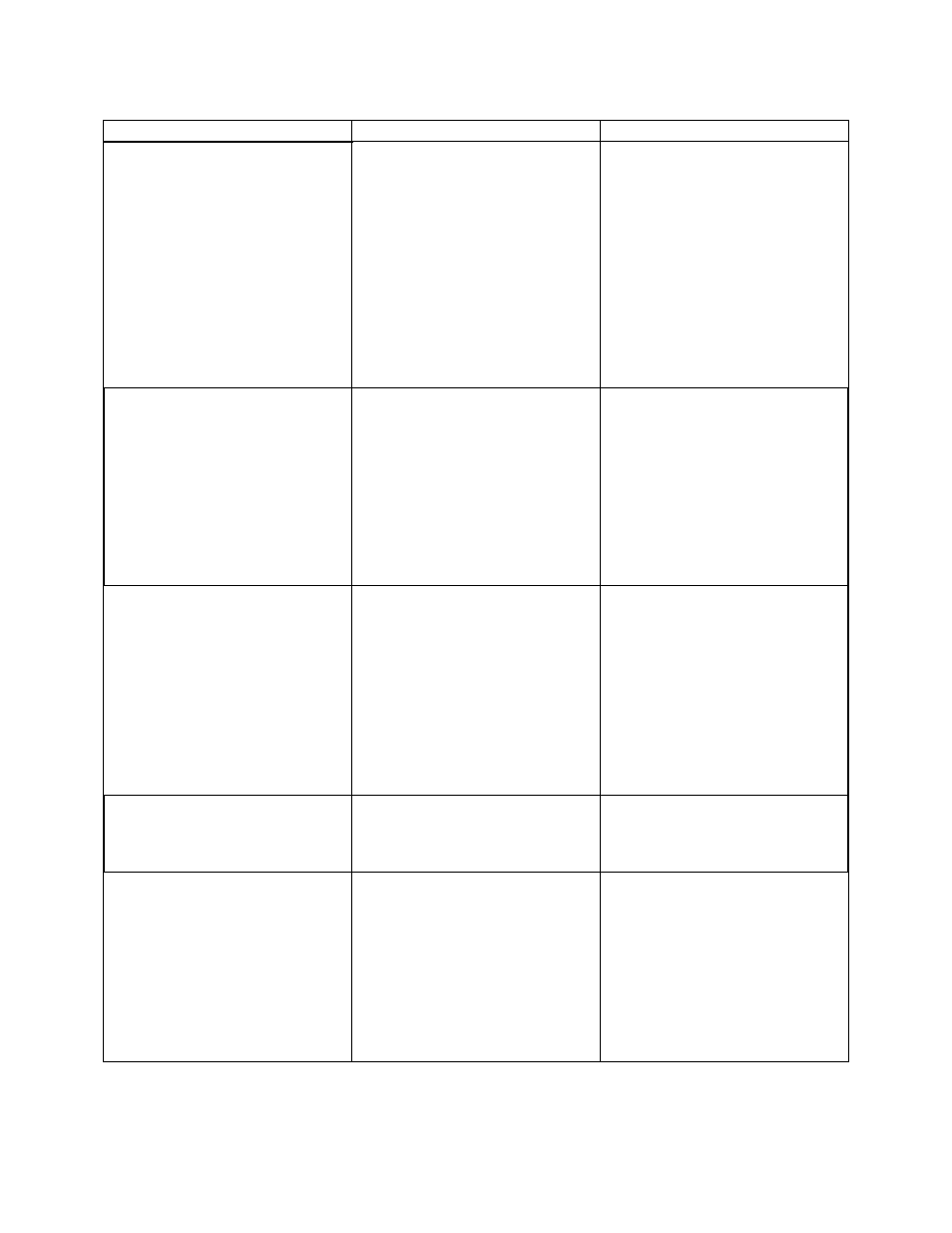

Trouble-Remedy Guide

Trouble Possible

Cause

Remedy

a. Safety valve (RV-1) leaking or

frozen open.

a. Thaw out valve or replace if

necessary.

b. Rupture disc (BD) rupture.

b. Replace rupture disc.

c. Piping leaks to atmosphere.

c. Leak test and repair piping.

d. Pressure building solenoid (V-4)

failure.

d. Check fuse and wiring. Clean,

seat, rebuild, or replace solenoid

valve if necessary.

e. Excessive product withdrawal.

e. Check for leaks downstream.

Reduce product use.

f.

Controller off or not started.

f. Turn on controller and pull start

button.

1. Pressure low, controller error text

“Vessel Pressure Low” or

“Pressurization Time Out”.

g. Excessive frost on pressure

building coils.

g. Thaw pressure building coils.

a. Extensive shutdown time.

a. No remedy.

b. Low withdrawal rate.

b. No remedy.

c. Malfunction of pressure

building circuit.

c. Clean, rebuild, or replace

pressure building solenoid valve

(V-4).

d. Malfunction of pressure gauge

(PI) or pressure transmitter (PT-

2).

d. Compare gauge to transmitter

reading. Replace defective unit.

2. Excessive system pressure.

e. Bad vessel vacuum.

e. Have vessel repaired and re-

evacuated.

a.

Leaking gauge lines.

a. Test and repair leaks.

b.

By-pass valve open.

b. Close by-pass valve.

c.

Blown fuse.

c. Check for electrical short; replace

fuse.

d.

Liquid level transmitter (PT-1)

damaged or faulty.

d. Replace liquid level transmitter

(PT-1).

e.

Gauge lines reversed.

e. Connect properly.

f. Wiring

fault.

f.

Check

and fix transmitter wiring.

3. Erratic or erroneous liquid level

readings.

g.

Plugged gauge lines.

g. Disconnect lines at liquid level

transmitter (PT-1) and test for

flow.

a.

Dirt or ice in valve.

a. Thaw out valve. Replace if

necessary.

b.

Improper valve set point.

b. Replace valve.

4. Leaking relief valve (RV).

c.

Damaged valve seat.

c. Replace valve.

a.

Excessive vessel pressure.

a. Refer to Step 2, this section.

Replace rupture disc.

b.

Defective rupture disc.

b. Replace rupture disc.

c.

Atmosphere corrosion and/or

disc fatigue.

c. Replace rupture disc.

d.

Interior disc corrosion.

d. Blow out safety device line.

Replace rupture disc.

e.

Improper rupture disc.

e. Install correct rupture disc.

5. Ruptured pressure vessel rupture

disc (BD).

f.

Relief device failed.

f. Replace relief device and rupture

disc.