Taylor-Wharton Auto Fill Laser Pak User Manual

Page 19

19

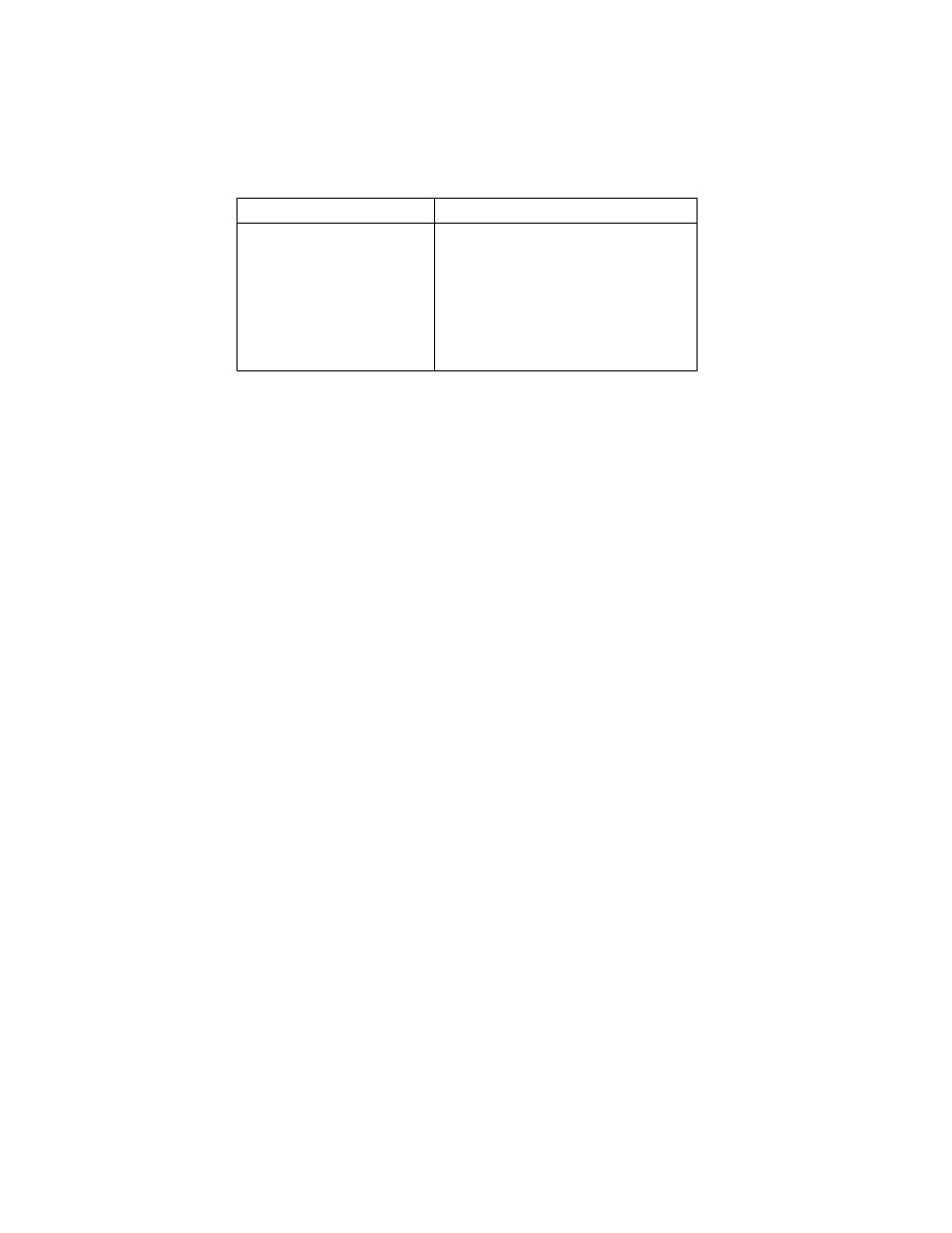

Low Pressure Alarm – If the pressure of the vessel in Supply mode drops below this value the error alarm

and error indicator light will be activated.

System Vent to Bulk – The system will not vent back to the bulk tank if this parameter is turned off.

Setting Initial

Setting

Unit

Pressure Builder Open

450

psig

Pressure Builder Range

30

psi

Vent to Bulk

510

psig

Bulk Pressure High

230

psig

Low Pressure Alarm

370

psig

System Vent to Bulk

On

On/Off

Figure 12: Initial Settings

First Fill

The first fill should be performed manually. This is necessary to properly purge and control cooling of the

inner vessels. Calibration of the level transmitters is also covered in this procedure. It is recommended that

this procedure be performed once a year to recalibrate the level transmitters.

CAUTION: Follow the safety precautions at the beginning of this manual. Accidental contact with liquid or

cold gas can occur when operating the solenoid valve manual overrides.

1.

Press the start/stop button on the control panel inward. Turn the power switch to the “On” position.

Open the control panel door. With power on and the start/stop button pressed inward settings may be

adjusted on the graphic interface (Panel View) without running the system.

CAUTION:

Do not touch the wiring inside the control panel while power is activated. The

operator should touch only the graphic interface located in the upper right corner.

2.

Make sure that the manual override handles of all eight of solenoid valves are in the closed position.

The override is closed when the handle is turned counterclockwise fully. When closing the override,

the handle will move downward, away from the valve body.

3.

Slowly open the bulk liquid withdrawal valve. Open the valve completely.

4.

Turn the manual override handles of the vent solenoid valves (V-3A & V-3B) until venting begins.

Turn the handles two additional turns. The vessels are now being filled. First fill should be

performed slowly. The rate of filling can be adjusted by throttling the vent solenoid valves.

5.

While the vessels are filling, go to the control panel. On the graphic interface, from the default

screen, press “F3” to enter the setting adjustment screen. Press “F1” to enter the level scale screen.

The row labeled “Vessel Level” indicates the liquid level, in inches of water, for each of the vessels.

The vessel level reading will update continuously.