Qmark MSPH - Plenum Rated Unit Heater User Manual

Page 2

2

GENERAL INFORMATION:

The PRH Series plenum heaters are design certified by ETL to

Standard for Heating and Cooling Equipment ANSI / UL 1995,

CAN/CSA C22.2 No. 236-05, third edition. The PRH Series

plenum heaters are unique application heaters approved for

installation in a concealed space, an area between a finished

ceiling and drop ceiling, a plenum space or inside a plenum.

These series of heaters may be installed in areas that are not

readily accessible and may be installed with a duct system or

installed for free-air discharge. Always install units to operate

within the intended temperature rise, intended external static

pressure range and in the intended installation position (see

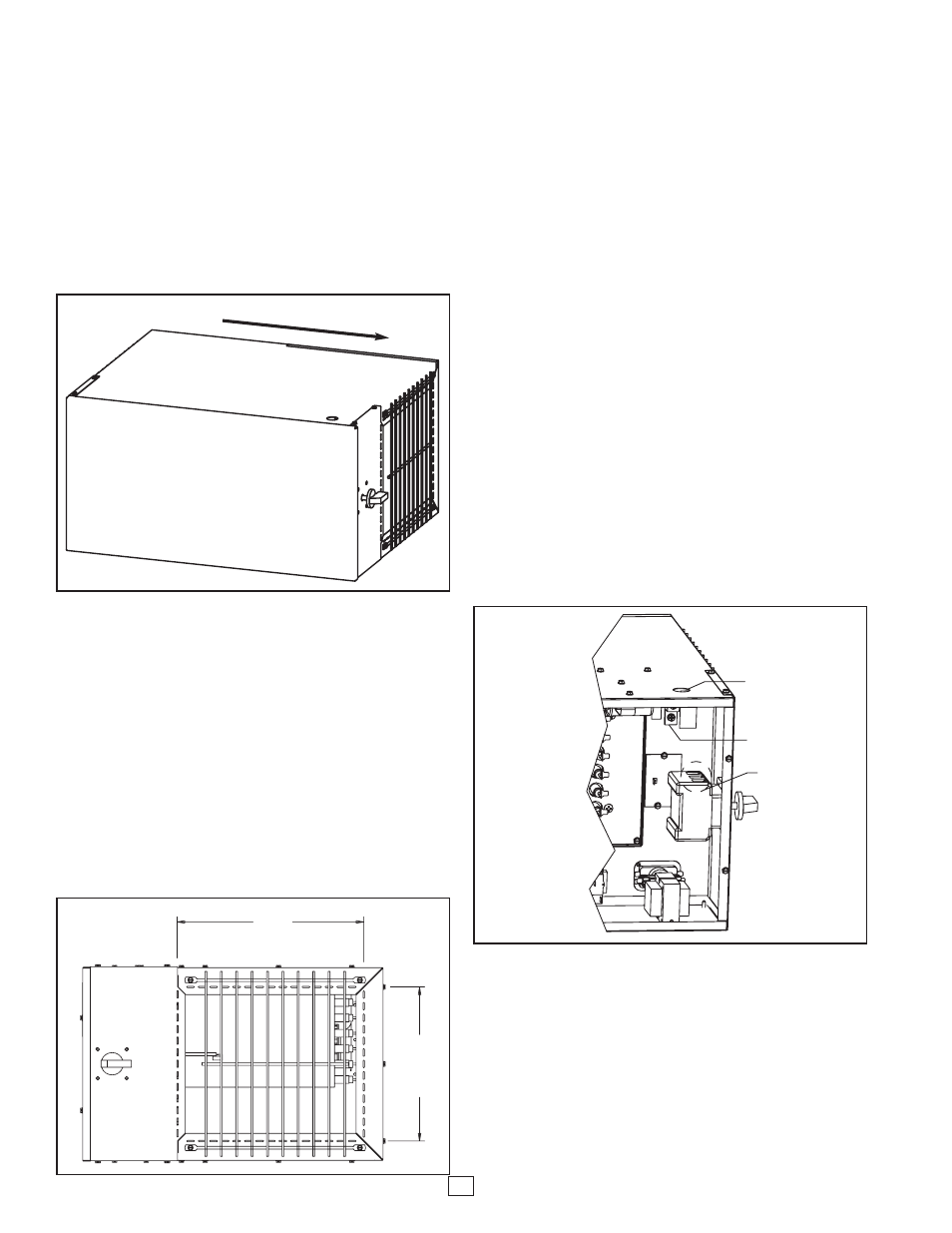

Figure 2 horizontal-right).

MOUNTING:

The PRH Series plenum heaters are intended to be mounted

in the horizontal-right installation position (see Figure 2) and in

a suspended manner. The unit can be rotated on its axis in

any position needed (can not be mounted vertically). Suspend

the unit from the building structure in a horizontal plane. Units

must be independently supported. Support channels or straps

are intended to be permanently attached to unit frame/housing.

Be careful not to obstruct access to control panel with support

channels or straps. DUCT CONNECTIONS / DUCTING:

The PRH Series plenum heaters may either be installed for

free-air discharge or with a duct system. The proper sizing of

warm air ducts is essential in providing satisfactory heating

operation. Ductwork should be in accordance with the latest

editions of NFPA-90B (Warm Air Heating and Air Conditioning

Systems) or Canadian equivalent. Every PRH model is

equipped with an inlet and outlet grille for free-air discharge.

Both grilles are intended to be removed when connecting to a

duct system. The inlet and outlet ends of the unit are

equipped with perforated flanges to aid in forming both inlet

and outlet duct flanges (see Figure 3).

These perforations will aid in forming a rectangular inlet and

outlet duct flange if they are desired for connection to the duct

system. The unit is designed for a rectangular flange duct con-

necting and the clear area around the flange is intended for

screw penetration. This feature aids in attaching the duct work

to the unit so that the ductwork may be fastened and sealed to

the unit.

CONTROL ACCESS:

The front door allows access to all the controls and compo-

nents within the unit. The unit is design certified for 0” clear-

ances however, while installing the unit, be careful not to

obstruct access to this control panel. This panel allows access

to the unit for making the power connection, the thermostat

connection and is intended to allow access to all the internal

components that make up the unit.

ELECTRICAL CONNECTIONS:

All field wiring must comply with NEC and local codes.

N

NO

OT

TE

E:: S

SE

EE

E P

PA

AG

GE

E 3

3 &

& 4

4 F

FO

OR

R W

WIIR

RIIN

NG

G D

DIIA

AG

GR

RA

AM

MS

S

All units are designed for a single point connection to supply

power to the fan and electric heater. The PRH series plenum

heaters are shipped standard with a 80 amp 3-pole disconnect

switch. Field power connections are made to the line side of

this disconnect switch (see Figure 4).

Each unit is equipped with a grounding lug for ground connec-

tion. The unit must be properly grounded to comply with NEC

and local codes. Before making the power connection, insure

that the line voltage to the unit matches the ratings located on

the nameplate of the unit. All units should have copper wire

sized for 125% of nameplate amperage. Disconnect the power

supply before wiring the unit and insure the disconnect switch

is in the OFF position while making power connections or ser-

vicing the unit. The unit cabinet has a 7/8” electrical knockout

for routing power supply to the disconnect switch (see

Specifications section for knockout location). Should the unit

require a larger electrical conduit connection, this electrical

knockout is intended to serve as the pilot hole in order to field

convert to larger electrical connections.

AIRFLOW DIRECTION

Figure 2

12” Small

11.64” Large

10”

Small

15.32”

Large

Figure 3

Electrical

Knocknot

Ground

Connection

Power

Connection

Figure 4