Wiring diagrams, Danger, Mounting and wiring – Qmark KCJ - Institutional Electric Convectors User Manual

Page 2: Operation and maintenance

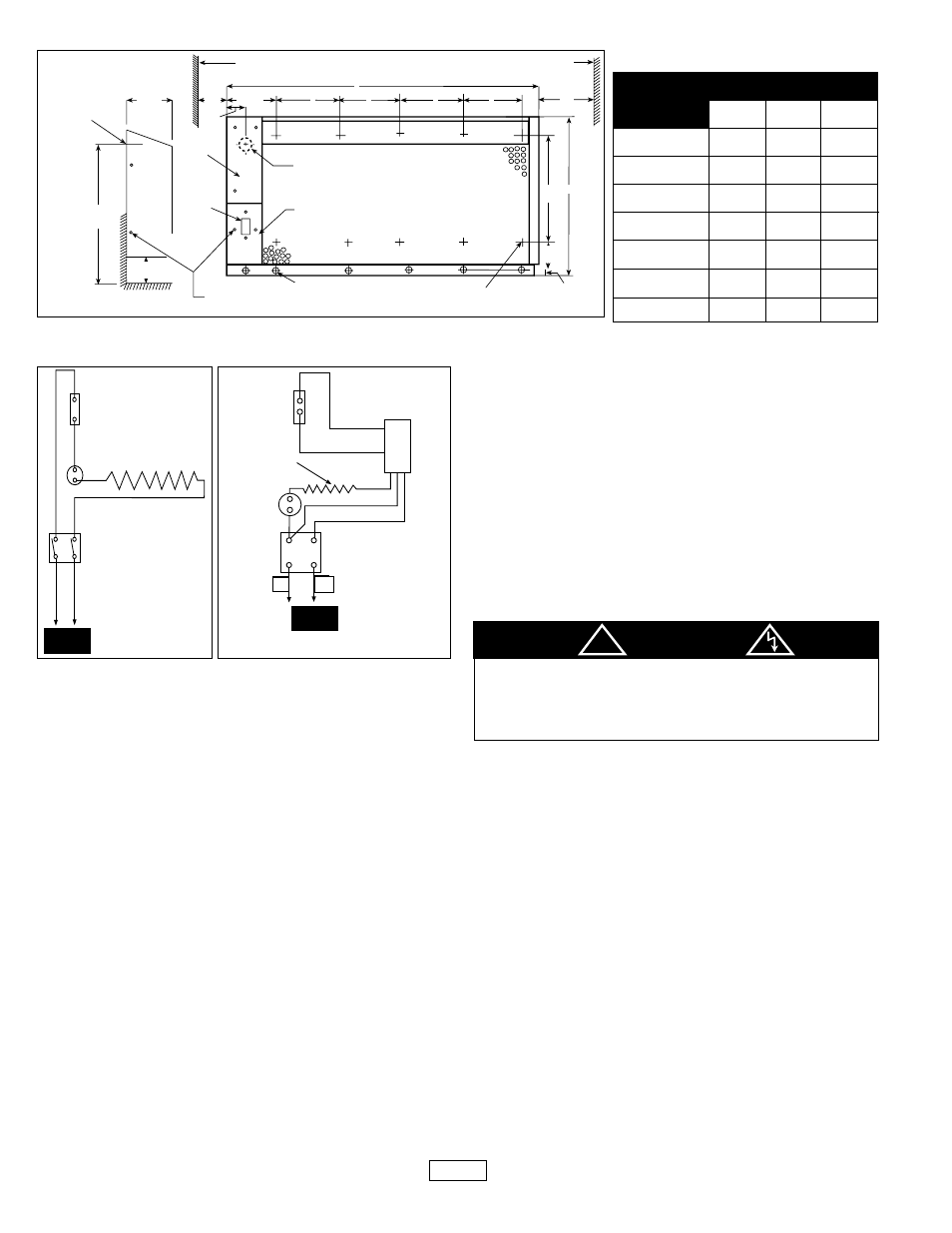

MOUNTING AND WIRING

NOTE: Electrical wiring is to be sized in accordance with National

Electric Code and local codes using at least 75°C type RH, THW

or equivalent insulated wire. See chart located on page 3 for

amp. loads.

1.

Locate on vertical wall with length of heater positioned

horizontally.

2.

When selecting a mounting location, the following minimum

distances must be observed to insure proper operation.

a.

Six (6") inches (152mm) from bottom of heater to floor.

b.

One (1.5") inch (38mm) from wall or other obstruction to

the right or left side of heater.

3.

Do not mount heater in a recess, since such mounting

interferes with free air circulation, increases temperature and

prevents proper thermostat operation.

NOTE: Unit is shipped with non-tamper resistant screws securing

front cover. Remove screws and discard.

4.

Mount the rear panel assembly of the heater to the wall using

the 11/32" (8.7mm) diameter holes (bolts and wall anchors to be

supplied by customer).

5.

Install the perforated cover by hooking the top edge of the

cover over the top edge of rear panel.

6.

Attach the bottom lip of the perforated cover to the wall using

the 1/4 - 20 x 1" tamper proof screws provided (Wall anchors

to be supplied by customer).

7.

Electrical wiring must be brought into heater through 1-3/32"

(27.8mm) diameter hole located in the rear panel.

8.

Grounding conductor must be connected to the green pigtail

lead.

9.

Make the proper connections following the wiring diagram.

Install disconnect switch cover assembly with (2) #8 x 5/8"

tamper proof screws (provided).

10. Adjust thermostat to the desired setting. Install top access

cover with (4) #8 x 5/8" tamper proof screws (provided).

OPERATION AND MAINTENANCE

To assure efficient operation, follow the simple instructions listed

below.

TO CLEAN HEATER

Because of the convection heating principle which depends upon

a circulation of air through the finned element, dust particles will

periodically be deposited between the fins, and should be

removed occasionally for maximum efficiency of the heater. With

front cover removed, a vacuum cleaner with proper attachments

can easily be worked along the top and bottom of the finned ele-

ment to clear it of dust deposits.

TO REPAINT, IF DESIRED

The baked enamel finish was chosen to blend with interior decors.

If you wish to repaint the heaters, use high quality household

enamel. No primer is necessary. Do not use rubber base paint.

Paint heater front cover only. Do not paint heating element.

HAZARD OF ELECTRIC SHOCK. DISCONNECT ALL

POWER BEFORE ATTEMPTING TO SERVICE THE

HEATERS.

WATTAGE

DIMENSIONS

A

24"

608mm

28"

709mm

36"

912mm

48"

1216mm

60"

1520mm

72"

1824mm

96"

2432mm

18"

456mm

18.25"

462mm

B

19.1”

485 mm

11.5"

291mm

15.0"

380mm

14.3"

362mm

13.75"

348mm

16.75"

424mm

C

-

11.5"

291mm

16"

405mm

14.3"

362mm

13.75"

348mm

16.75"

424mm

400

500

750

1000

1250

1500

2000

2

center line of

1-3/32" dia. hole

in rear panel

for customer entry.

5"

(127mm)

19"

Min.

(481mm)

6" to floor Min.

(152mm)

Tamper Proof

Screws 10 - 32 x 1/2"

Mounting holes 11/32" (8.7mm) dia. for mtg.

front cover to wall by using 1/4 - 20 x 1"

tamper proof screws supplied.

Mounting holes 11/32" (8.7mm)

dia. for mtg. rear panel to wall

Disconnect

Switch

Top

Access

Cover

Conduit Entrance

Disconnect Switch Cover

1"

Min.

1 3/4"

(25mm)

3"

(76mm)

B

C

C

A

other obstruction

TO

(25mm)

1"

Min.

or other obstruction

10"

16"

3 7/16"

1/4"

( 8 7 m m )

(6.3mm)

(253mm)

(405mm)

(25mm)

C

(all models)

(1000W, 1250W, 1500W) (1250W & 1500W only)

Element

Thermostat

Disconnect

Switch

Limit

L1

L2 or N

TO POWER

CIRCUIT

!

DANGER

(1000W thru 2000W)

(1250W thru 2000W)

Red

Blue

Black

Red

White

Thermostat

High

Limit

Element

Disconnect

Switch

N

L1

Transformer

Relay

120V thru

277V ONLY

347V and

600V ONLY

(347V) N

(600V)L2

TO POWER

CIRCUIT

Wiring Diagrams

L1

N