Qmark CP - Electric Infrared Heating Control Panels User Manual

Page 3

TIME DELAY CONTROLLER

The single contactor panel with a suffix CT in its Model Number

(i.e. CP404802CT) is provided with a time delay timer which

energizes a specific load in an area for intermittent periods of

time. It comes with a momentary push-button switch which acti-

vates the heating load for a preset cycle (adjustable between 1

and 30 minutes). The system is de-energized once the timer has

cycled. Once the cycle has started any push of the button will no

longer affect the timing. The cycle has to finish, the system has

to come off, and only then can the system restart for another

cycle with the push of the button. Since the option to connect a

remote controller is always available, the use of such a remote

controller will override the intermittent cycling of the system. The

system will come ON and OFF instantaneously with the remote

thermostat or controller. The system will stay energized for as

long as the remote controller keeps calling for heat. Only when

the remote thermostat is not calling for heat (R & W open) can

intermittent cycling start. Thus, if only intermittent heating is

desired, the panel will function without the need for a remote

controller. The terminal R and W in the panel must be kept open.

This is ideal for bus stops, loading docks, smoking areas or

remote work stations. A remote controller would be used to

maintain a certain area from freezing and any temporary user of

the area would augment the heat requirement with a push of a

button. The timer has the facility to be able to adjust its time

period in the field. It is pre-set from the factory at the maximum

30 minute delay.

SINGLE PHASE APPLICATIONS

These control panels were primarily designed to handle three

phase loads. This is why the contactors and power supply ter-

minal blocks provided with each panel have three poles. Except

for control panels with Time Delay and Percentage Timer options

contactors are rated and wired for 50 amps per pole. Where

fuses are required the fuse blocks provided have three poles

rated at 60 amps per pole. If the power supply is single phase

and the load is single phase, these panels can be used provided

the electrical loading on the wires and components are within

acceptable limits. The electrician must see to it that proper termi-

nals are chosen (L1 & L2 for single phase) such that the primary

of the control transformer is energized . See typical wiring dia-

grams, Figures 1 and 3.

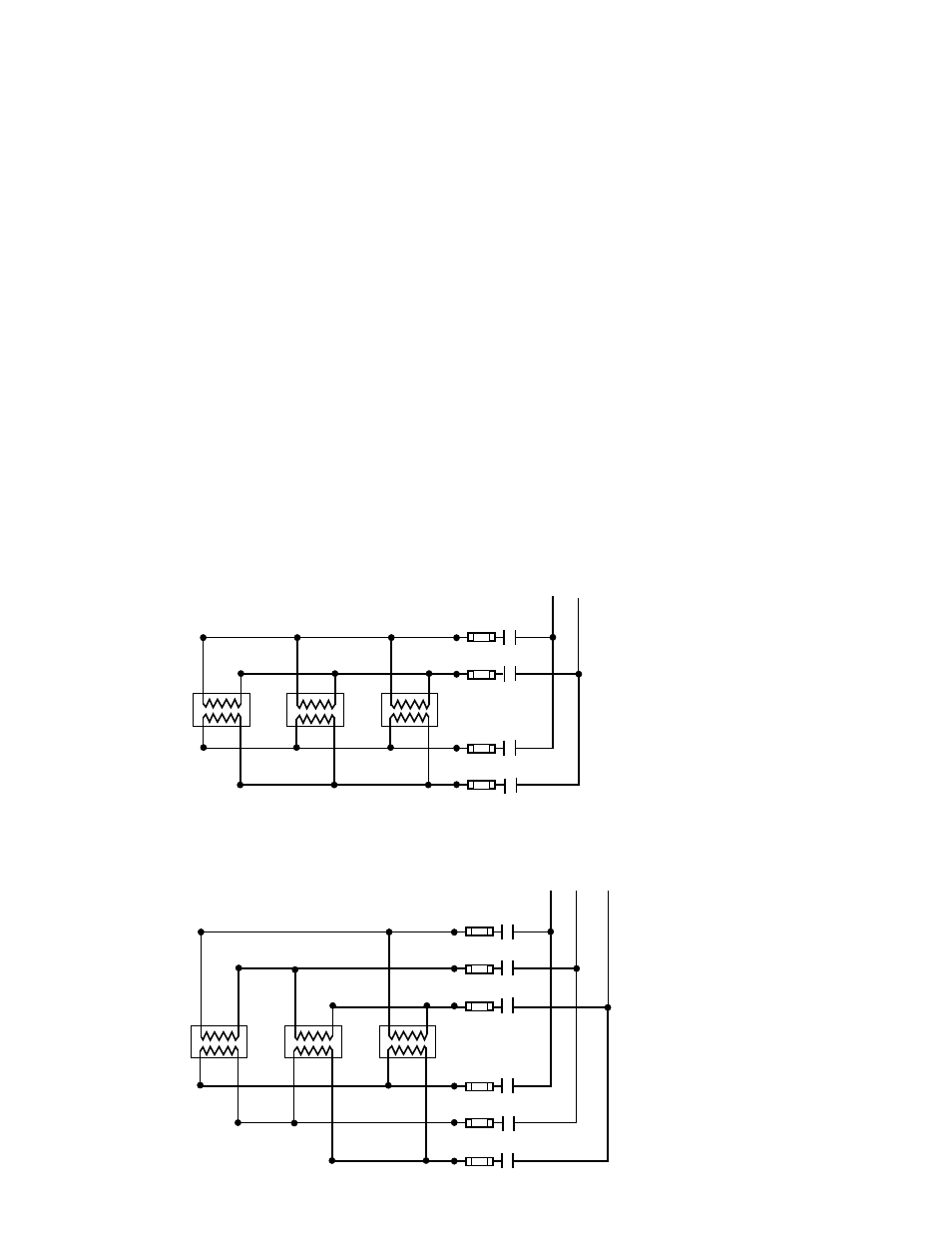

BALANCED THREE PHASE APPLICATIONS

Single phase infrared heaters can be wired to a three phase cir-

cuit under the following conditions. In applications where the

infrared heaters are single phase and the supply power is three

phase, the electrical load must be balanced across each of the

three phases. In order to accomplish this the heaters must be

used in combinations of three heaters equally rated. In this

installation, one heater would be wired to L1 and L2, the second

would be wired to L2 and L3, and the third wired to L3 and L1.

See typical wiring diagrams, Figures 2 and 4

L1

L1

L2

L2

C1

C2

L3

L3

L1 L2

L3

HTR 1

HTR 2

HTR 3

TYPICAL WIRING DIAGRAMS

NOTE: Control wiring not shown for clarity. Refer to wiring diagrams with control panels.

Figure 2: Three phase supply- Three double element

heaters two stage control per heater.

Balanced three phase with two contactor panel.

L1

L1

L2

L2

C1

C2

L1 L2

HTR 1

HTR 2

HTR 3

Figure 1: Single phase supply- Three double element

heaters two stage control per heater with two

contactor panel