Qmark QWD - Washdown Corrosion Resistant Unit Heaters User Manual

Page 3

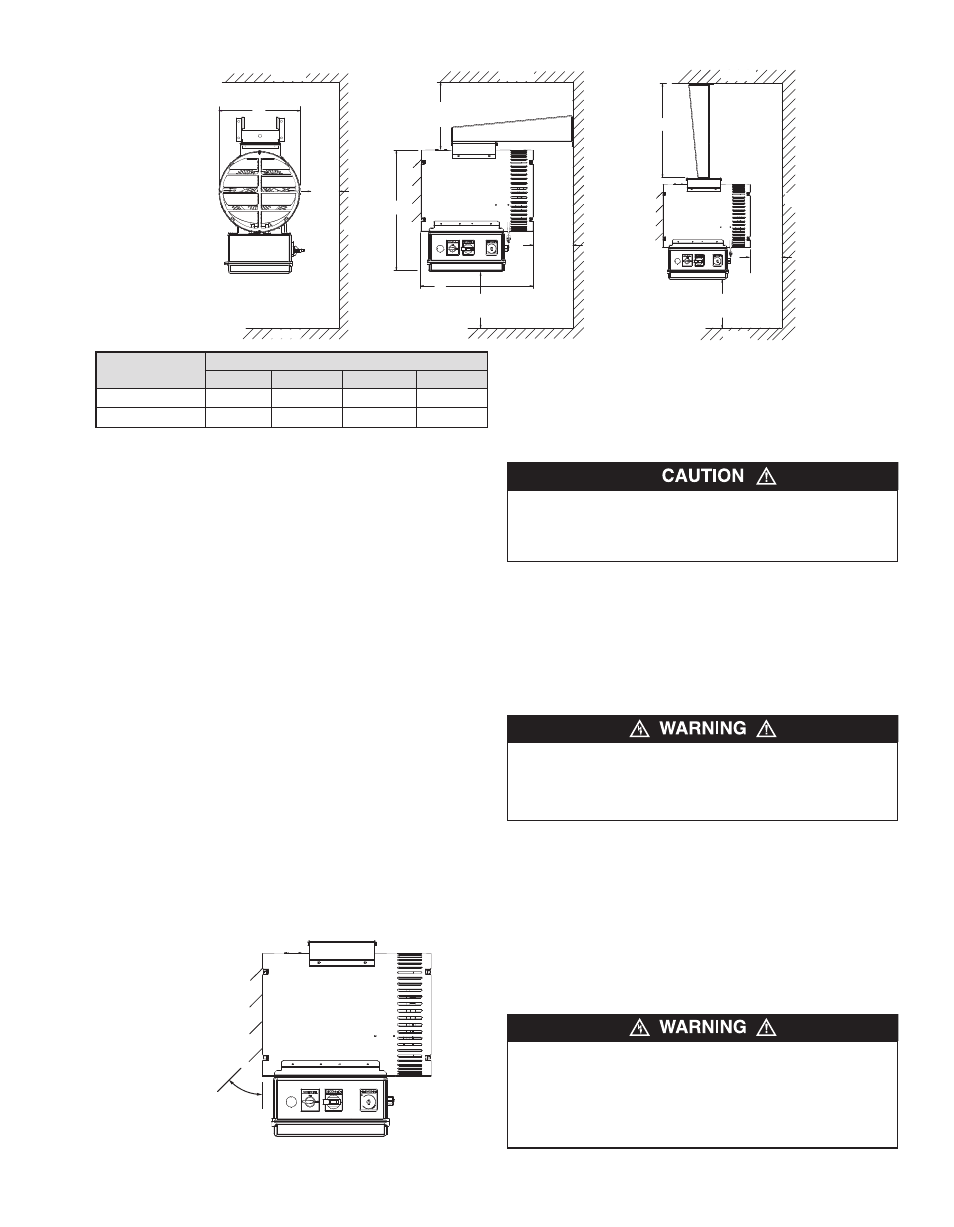

small rooms can be heated by one unit heater. Where two walls

are exposed, the heater should be mounted as shown in

figure 1.

Large rooms require multi-unit installations. Number and capaci-

ty of units will be determined by volume of building and square

feet of floor area to be heated. Arrange units to provide perimeter

air circulation where each unit supports the air stream from

another.

Mounting Heaters with supplied Universal

Mounting Bracket

NOTICE — These heaters are designed for wall and ceiling

mounting with horizontal air discharge only. other modes of

mounting voids factory warranty.

1. Height above floor

A. in areas where ceiling height is more than 12 feet (3658

mm), recommended mounting height is approximately 10

feet (3048 mm) to underside of heater.

B. for ceiling heights of 12 feet (3658 mm) or less, maximum

mounting height is determined by use of the mounting

bracket offered for these heaters. Minimum spacing to ceil-

ing is 9” (229 mm). (see figure 2.)

C. in either case the minimum mounting height is 7 feet (2134

mm) from floor to bottom of heater. (figure 2)

2. spacing to adjacent walls (see figure 2).

A. rear of case to back wall 6” (152mm) minimum.

B. side of case to side wall 8” (203 mm) minimum.

NOTE: if two or more units are operated in the same enclosed

air space, their discharges should be directed to aid in develop-

ment of mass air movement for uniform heat dispersal.

Wiring

Refer to wiring diagram included with the unit.

The wiring diagram can be found on the inside of the door to the

wiring compartment. should you have any questions, please

contact Technical service at 800-642-4328. Have your model

number found on the name plate for reference.

NOTE: All electrical wiring must be done according to National

Electrical and local codes by a qualified person.

IMPORTANT NOTE - Installation Screw Lug Torque: During

transportation it is possible screw lug connections can loosen.

After installation, before power is turned on to the heater, check

all screw lug connections for tightness to a recommended mini-

mum torque of 35 in-lbs. (3.9 N-m). A tool is included for tighten-

ing lugs in hard to reach locations

1. Connect heater according to the voltage and frequency spec-

ified on the nameplate.

2. All units are provided with control and power terminal blocks

for customer’s connection.

3. Protection against overheating is provided by an internal

automatic thermal cutout (manual reset cutout optional)

which opens the electric circuit if the normal air-flow is

restricted or stopped. Cutout automatically energizes heater

on removal of the obstruction. if optional manual reset is

tripped, determine cause before re-energizing.

ELECTriC sHoCK HAzArD. ANy iNsTALLATioN iNVoLV-

iNg ELECTriC HEATErs MusT BE PErforMED By A

quALifiED PErsoN AND MusT BE EffECTiVELy

grouNDED iN ACCorDANCE WiTH THE NATioNAL

ELECTriCAL CoDE To ELiMiNATE sHoCK HAzArD.

ALL ELECTriCAL CoNDuiT AND fiTTiNgs MusT BE LisTED

for WATErTigHT APPLiCATioNs To MAiNTAiN THE NEMA

4X ENCLosurE CLAssifiCATioN To PrEVENT HosE

DirECTED WATEr froM ENTEriNg ELECTriCAL BoX.

THE sysTEM DEsigNEr is rEsPoNsiBLE for THE

sAfETy of THis EquiPMENT AND sHouLD iNsTALL

ADEquATE BACK-uP CoNTroLs AND sAfETy DEViCEs

WiTH THEir ELECTriC HEATiNg EquiPMENT. WHErE THE

CoNsEquENCEs of fAiLurE CouLD rEsuLT iN

PErsoNAL iNJury or ProPErTy DAMAgE, BACK-uP

CoNTroLs ArE EssENTiAL.

3

Dimensions Inches (mm)

kW

A

B

C

D

2-10

13 (330)

19.5 (495)

18 (457)

19.5 (495)

12.5-39.0

20 (508)

31 (787)

27 (686)

24.2 (615)

A

Wall

Ceiling

Floor

6" Min.

(152 mm)

D

Ceiling

Wall

8" Min.

(203 mm)

B

Floor

7' Min.

(2134 mm)

7' Min.

(2134 mm)

9" Min.

(229 mm)

Wall

6"

(152 mm)

C

Ceiling

Floor

Figure 2

45° Minimum

Angle

Figure 3 - Louver Adjustment