Caution, Warning – Carrier SEER 48ES User Manual

Page 20

20

NOTE: If the problem causing the inaccurate readings is a

refrigerant leak, refer to the Check for Refrigerant Leaks section.

Indoor Airflow and Airflow Adjustments

UNIT OPERATION HAZARD

Failure to follow this caution may result in unit damage.

For cooling operation, the recommended airflow is 350 to

450 cfm for each 12,000 Btuh of rated cooling capacity. For

heating operation, the airflow must produce a temperature

rise that falls within the range stamped on the unit rating

plate.

CAUTION

!

NOTE: Be sure that all supply--and return--air grilles are open,

free from obstructions, and adjusted properly. Airflow can be

changed using the User Interface.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Disconnect electrical power to the unit and install lockout

tag before changing blower speed.

!

WARNING

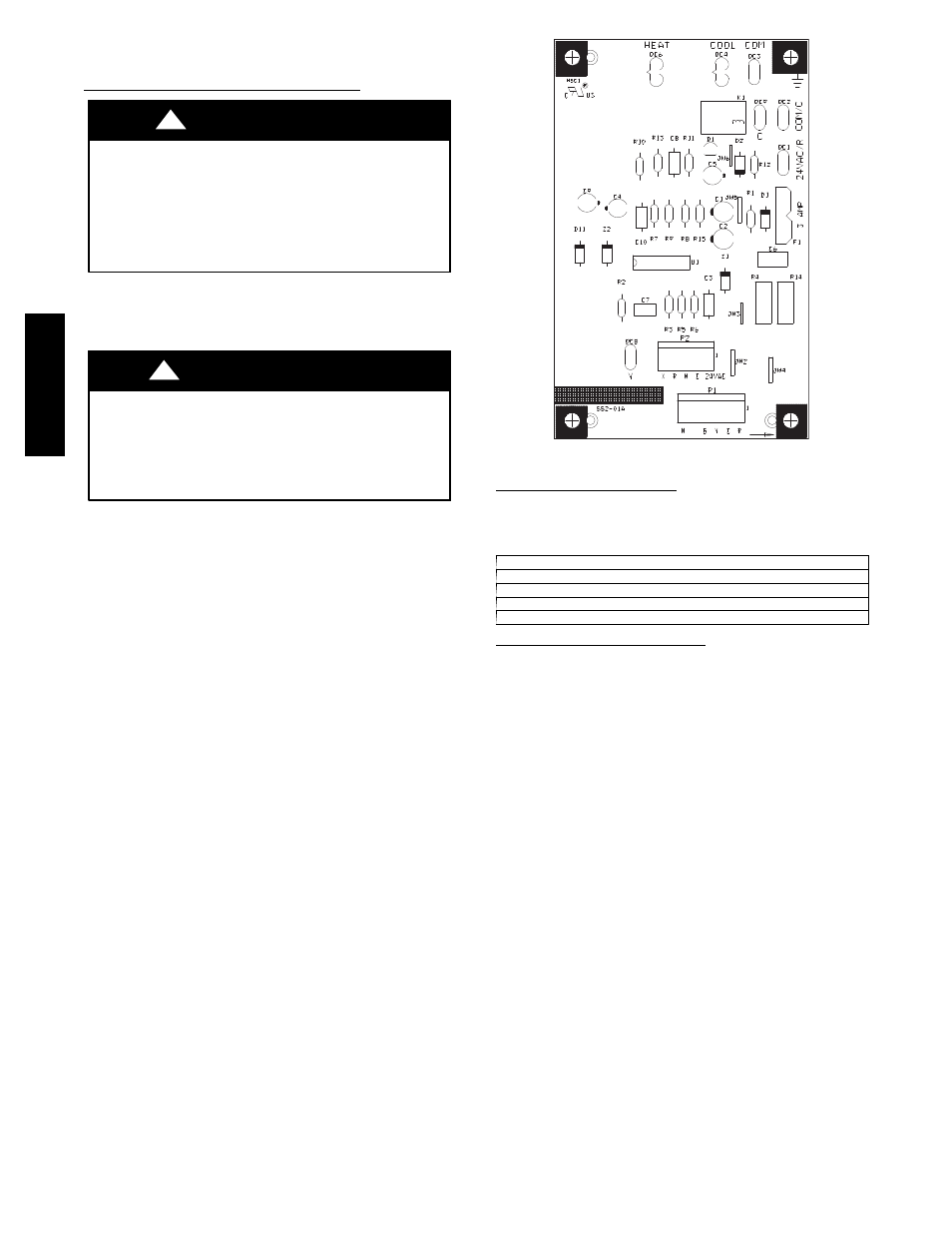

There are independent fan speeds for heating and cooling marked

“HEAT” and “COOL” on the interface fan board (IFB) (See Fig.

18). The unit is factory--shipped with heating and cooling speeds

noted in Table 9. There are 3 additional speed tap wires available

for use in either heating or cooling (For color coding on the indoor

fan motor leads, see Table 6). The additional 3 speed tap wires are

shipped loose with vinyl caps and are located in the control box,

near the interface fan board (IFB).

To change heating speed, remove the vinyl cap off of the desired

speed tap wire (Refer to Table 6 for color coding). Remove the

current speed tap wire from the “HEAT” terminal on the interface

fan board (IFB) (see Fig. 18) and place vinyl cap over the

connector on the wire. Connect the desired speed tap wire to the

“HEAT” terminal on the IFB. Table 9 shows the temperature rise

associated with each fan speed for a given static pressure. Make

sure that the speed chosen delivers a temperature rise within the

rise range listed on the unit rating plate.

To change cooling speed, remove the vinyl cap off of the desired

speed tap wire (Refer to Table 6 for color coding). Remove the

current speed tap wire from the “COOL” terminal on the interface

fan board (IFB) (see Fig. 18) and place vinyl cap over the

connector on the wire. Connect the desired speed tap wire to the

“COOL” terminal IFB. For optimum performance, add the wet coil

pressure drop in Table 10 to the system static to determine the

correct cooling airflow speed in Table 9 that will deliver the

nominal cooling airflow as listed in Table 1 for each size.

NOTE: For cooling operation, the recommended airflow is 350 to

450 CFM for each 12,000 Btuh of rated cooling capacity.

A07793

Fig. 18 -- Interface Fan Board (IFB)

Continuous Fan Operation

The continuous fan operates at the same fan speed as cooling

operation.

Table 6 – Color Coding for Indoor Fan Motor Leads

Black = High Speed

Orange = Med--- High Speed

Red = Med Speed

Pink = Med--- Low Speed

Blue = Low Speed

Cooling Sequence of Operation

With the room thermostat SYSTEM switch in the COOL position

and the FAN switch in the AUTO position, the cooling sequence

of operation is as follows:

1. When the room temperature rises to a point that is slightly

above the cooling control setting of the thermostat, the

thermostat completes the circuit between thermostat

terminal R to terminals Y and G.

2. The normally open contacts of energized contactor (C) close

and complete the circuit through compressor motor

(COMP) to condenser (outdoor) fan motor (OFM). Both

motors start instantly.

3. The set of normally open contacts of energized relay BM

close and complete the circuit through evaporator blower

(indoor) fan motor (IFM).

NOTE: Once the compressor has started and then stopped, it

should not be started again until 5 minutes have elapsed. The

cooling cycle remains on until the room temperature drops to a

point that is slightly below the cooling control setting of the room

thermostat. At this point, the thermostat breaks the circuit between

thermostat terminal R to terminals Y and G. These open circuits

deenergize contactor coil C. The condenser and compressor motors

stop. After a 60--sec. delay, the blower motor stops. The unit is in a

standby condition, waiting for the next call for cooling from the

room thermostat.

48E

S