Warning, Caution, Maintenance – Carrier SEER 48ES User Manual

Page 27

27

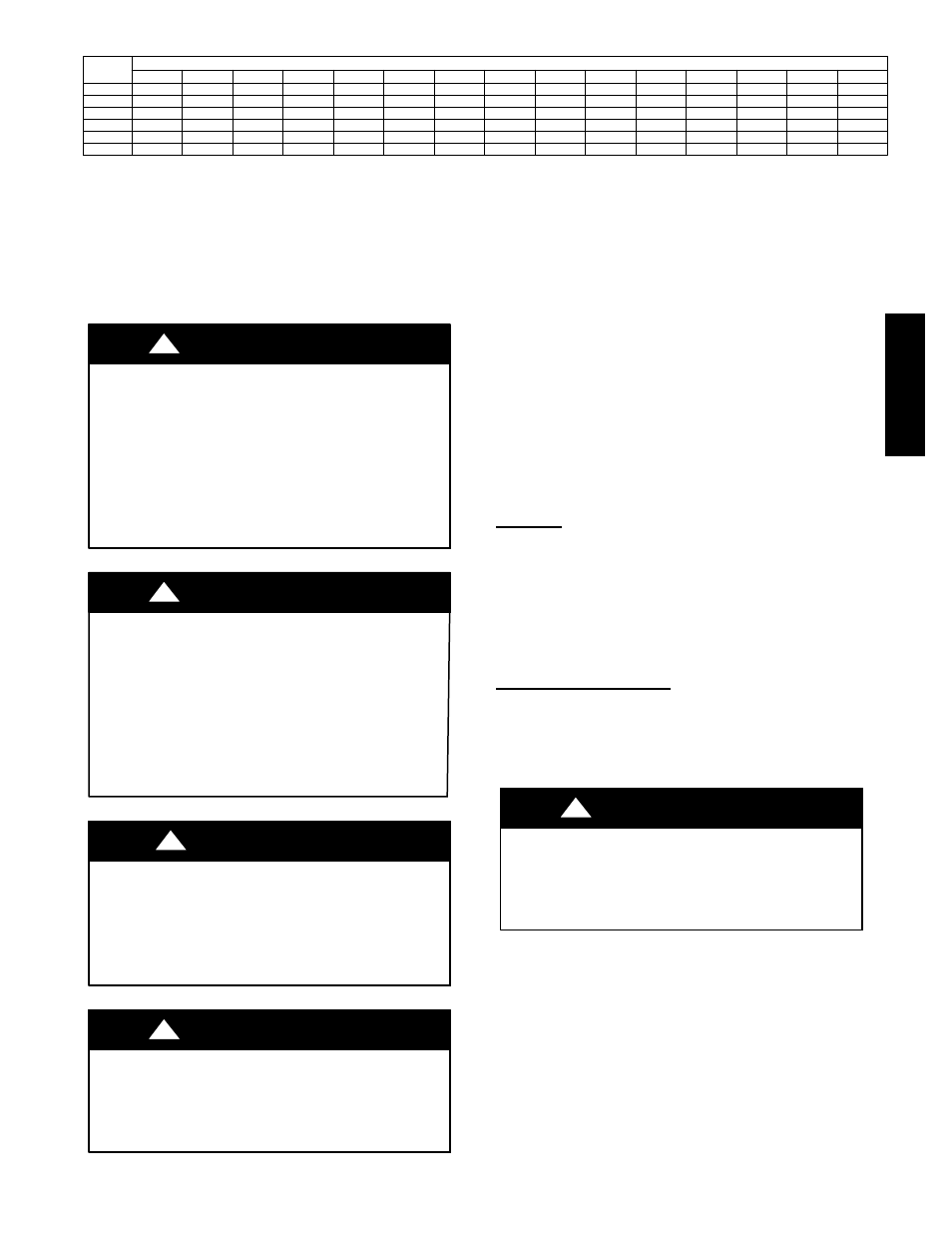

Table 10 – 48ES Wet Coil Pressure Drop (IN. W.C.)

UNIT

SIZE

STANDARD CFM (S.C.F.M)

600

700

800

900

1000

1100

1200

1300

1400

1500

1600

1700

1800

1900

2000

024

0.030

0.037

0.044

0.053

0.063

---

---

---

---

---

---

---

---

---

---

030

---

0.037

0.044

0.053

0.063

0.072

0.081

0.105

---

---

---

---

---

---

---

036

---

---

---

0.055

0.060

0.090

0.100

0.110

0.140

---

---

---

---

---

---

042

---

---

---

---

0.045

0.050

0.060

0.065

0.075

0.080

0.090

0.094

0.110

---

---

048

---

---

---

---

---

---

0.041

0.063

0.085

0.100

0.104

0.110

0.120

0.130

---

060

---

---

---

---

---

---

---

---

---

0.060

0.065

0.072

0.077

0.085

0.100

MAINTENANCE

To ensure continuing high performance and to minimize the

possibility of premature equipment failure, periodic maintenance

must be performed on this equipment. This

unit should be

inspected at least once each year by a qualified service person. To

troubleshoot unit, refer to Table 11, Troubleshooting Chart.

NOTE TO EQUIPMENT OWNER: Consult your local dealer

about the availability of a maintenance contract.

PERSONAL

INJURY

AND

UNIT

DAMAGE

HAZARD

Failure to follow this warning could result in personal

injury or death and unit component damage.

The ability to properly perform maintenance on this

equipment requires certain expertise, mechanical skills,

tools and equipment. If you do not possess these, do not

attempt to perform any maintenance on this equipment,

other than those procedures recommended in the Owner’s

Manual.

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow these warnings could result in personal

injury or death:

1. Turn off electrical power to the unit and install lock out

tag before performing any maintenance or service on this

unit.

2. Use extreme caution when removing panels and parts.

3. Never place anything combustible either on or in contact

with the unit.

!

WARNING

UNIT OPERATION HAZARD

Failure to follow this caution may result in improper

operation.

Errors made when reconnecting wires may cause improper

and dangerous operation. Label all wires prior to

disconnecting when servicing.

CAUTION

!

ENVIRONMENTAL HAZARD

Failure to follow this caution may result in environmental

pollution.

Remove and re--cycle all components or materials (i.e. oil,

refrigerant, etc) before unit final disposal.

!

CAUTION

The minimum maintenance requirements for this equipment are as

follows:

1. Inspect air filter(s) each month. Clean or replace when

necessary.

2. Inspect indoor coil, drain pan, and condensate drain each

cooling season for cleanliness. Clean when necessary.

3. Inspect blower motor and wheel for cleanliness at the

beginning of each heating and cooling season. Clean when

necessary. For first heating and cooling season, inspect

blower wheel bi--monthly to determine proper cleaning

frequency.

4. Check electrical connections for tightness and controls for

proper operation each heating and cooling season. Service

when necessary.

5. Ensure electric wires are not in contact with refrigerant

tubing or sharp metal edges.

6. Check and inspect heating section before each heating

season. Clean and adjust when necessary.

7. Check flue hood and remove any obstructions, if necessary.

Air Filter

IMPORTANT: Never operate the unit without a suitable air filter

in the return--air duct system. Always replace the filter with the

same dimensional size and type as originally installed. See Table 1

for recommended filter sizes.

Inspect air filter(s) at least once each month and replace

(throwaway--type) or clean (cleanable--type) at least twice during

each cooling season and twice during the heating season, or

whenever the filter becomes clogged with dust and lint.

Indoor Blower and Motor

NOTE: All motors are pre--lubricated. Do not attempt to lubricate

these motors.

For longer life, operating economy, and continuing efficiency,

clean accumulated dirt and grease from the blower wheel and

motor annually.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Disconnect and tag electrical power to the unit before

cleaning the blower motor and wheel.

!

WARNING

To clean the blower motor and wheel:

1. Remove and disassemble blower assembly as follows:

a. Remove unit access panel.

b. Disconnect 5 pin plug and 4 pin plug from indoor

blower motor.

c. On all units remove blower assembly from unit.

Remove screws securing blower to blower partition and

slide assembly out. Be careful not to tear insulation in

blower compartment.

d. Ensure proper reassembly by marking blower wheel and

motor in relation to blower housing before disassembly.

48E

S