Warning, Caution, Step 9 — install duct connections – Carrier SEER 48ES User Manual

Page 10: 48e s

10

Table 2 – Maximum Gas Flow Capacity*

NOMINAL

IRON PIPE

SIZE (IN.)

INTERNAL

DIAMETER

(IN.)

LENGTH OF PIPE FT (m)†

10

(3)

20

(6)

30

(9)

40

(12)

50

(15)

60

(18)

70

(21)

80

(24)

90

(27)

100

(30)

125

(38)

150

(46)

175

(53)

200

(61)

1/2

.622

175

120

97

82

73

66

61

57

53

50

44

40

—

—

3/4

.824

360

250

200

170

151

138

125

118

110

103

93

84

77

72

1

1.049

680

465

375

320

285

260

240

220

205

195

175

160

145

135

1---1/4

1.380

1400

950

770

600

580

530

490

460

430

400

360

325

300

280

1---1/2

1.610

2100

1460

1180

990

900

810

750

690

650

620

550

500

460

430

*Capacity of pipe in cu ft of gas per hr for gas pressure of 0.5 psig or less. Pressure drop of 0.5---in. wc (based on a 0.60 specific gravity gas). Refer to Table,

National Fire Protection Association NFPA 54.

{

This length includes an ordinary number of fittings.

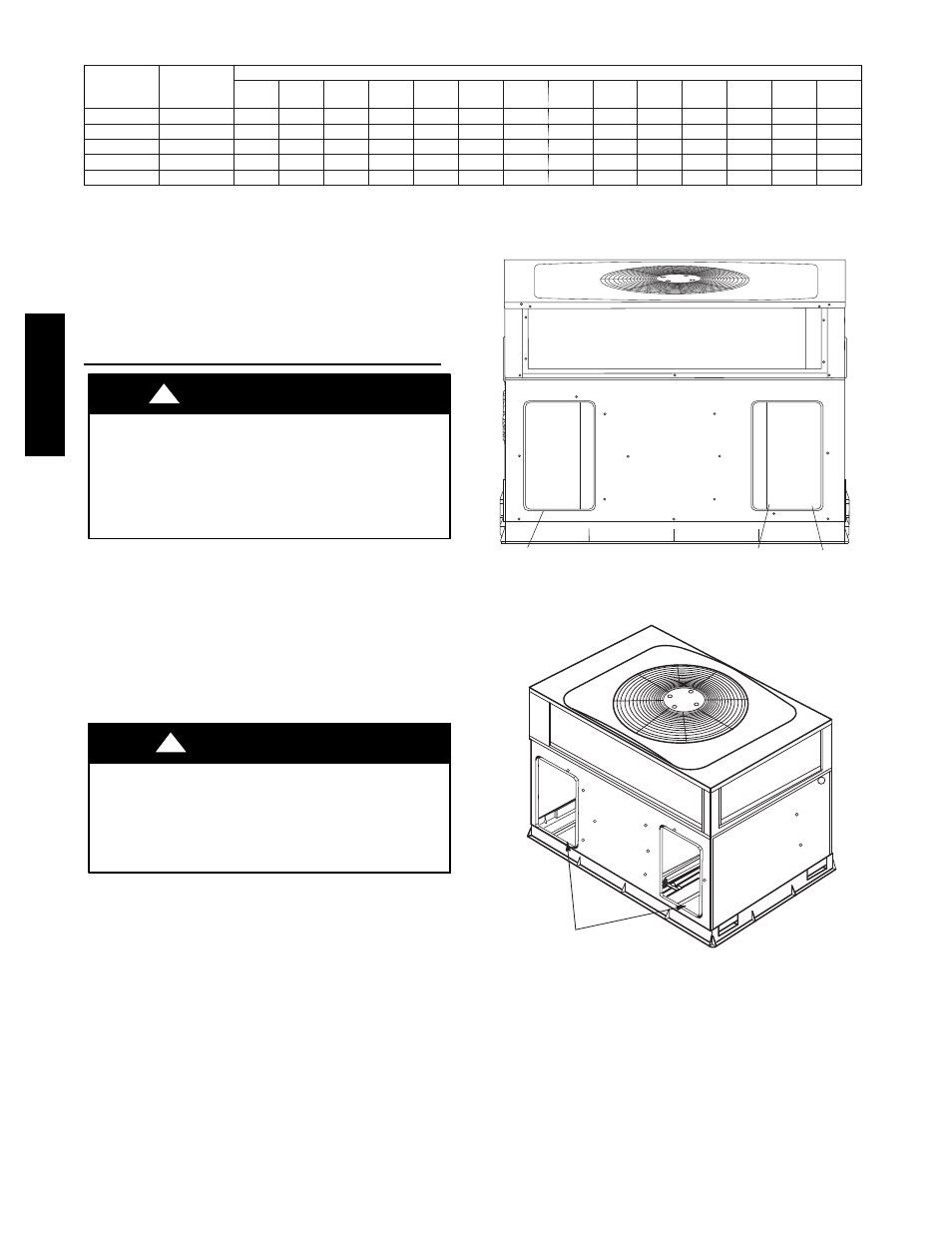

Step 9 — Install Duct Connections

The unit has duct flanges on the supply-- and return--air openings

on the side and bottom of the unit. For downshot applications, the

ductwork connects to the roof curb (See Fig. 3 and 4 for

connection sizes and locations).

Configuring Units for Downflow (Vertical) Discharge

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing or servicing system, always turn off main

power to system and install lockout tag. There may be

more than one disconnect switch.

!

WARNING

1. Open all electrical disconnects before starting any service

work.

2. Remove horizontal (metal) duct covers to access vertical

(downflow) discharge duct knockouts in unit base.

3. Use a screwdriver and hammer to remove the panels in the

bottom of the unit base (See Fig. 10).

4. If unit ductwork is to be attached to vertical opening flanges

on the unit base (jackstand applications only), do so at this

time.

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in property

damage.

Collect ALL screws that were removed. Do not leave

screws on rooftop as permanent damage to the roof may

occur.

CAUTION

!

5. It is recommended that the base insulation around the

perimeter of the vertical return--air opening be secured to

the base with aluminum tape. Applicable local codes may

require aluminum tape to prevent exposed fiberglass.

6. Cover both horizontal duct openings with the provided duct

covers. Ensure opening is air-- and watertight.

7. After completing unit conversion, perform all safety checks

and power up unit.

NOTE: The design and installation of the duct system must be in

accordance with the standards of the NFPA for installation of

nonresidence--type air conditioning and ventilating systems, NFPA

90A or residence--type, NFPA 90B; and/or local codes and

ordinances.

SUPPLY

DUCT

OPENING

RETURN

DUCT

OPENING

VENT HOOD

SHIPPING

LOCATION

A08492

Fig. 9 -- Supply and Return Duct Opening

VERTICAL DUCT COVERS

A08489

Fig. 10 -- Vertical Duct Cover Removed

48E

S