Caution, Check gas input, Adjust gas input – Carrier SEER 48ES User Manual

Page 14: 48e s

14

3. The induced--draft motor will start.

4. On a call for heating, the main burner should light within 5

sec. of the sparker being energized. If the burners do not

light, there is a 22--sec. delay before another 5--sec. try. If

the burners still do not light, this sequence is repeated. If the

burners do not light within 15 minutes from the initial call

for heat, there is a lockout. To reset the control, break the

24--v power to W.

5. The evaporator fan will turn on 45 sec. after the flame has

been established. The evaporator fan will turn off 45 sec.

after the thermostat has been satisfied. Please note that the

integrated gas unit controller (IGC) has the capability to

automatically reduce the evaporator “ON” delay and in-

crease the evaporator “OFF” delay in the event of high duct

static and/or partially--clogged filter.

Check Gas Input

Check gas input and manifold pressure after unit start--up (See

Table 4). If adjustment is required proceed as follows:

S

The rated gas inputs shown in Table 4 are for altitudes from sea

level to 2000 ft (610 m) above sea level. These inputs are based

on natural gas with a heating value of 1050 Btu/ft

3

at 0.65

specific gravity, or propane gas with a heating value of 2500

Btu/ft

3

at 1.5 specific gravity.

IN THE U.S.A.:

The input rating for altitudes above 2,000 ft (610 m) must be

reduced by 4% for each 1,000 ft (305 m) above see level.

For installations below 2,000 ft (610 m), refer to the unit rating

plate.

For installations above 2,000 ft (610 m). multiply the input by on

the rating plate by the derate multiplier in Table 3 for correct input

rate.

Table 3 – Altitude Derate Multiplier for U.S.A.

ALTITUDE FT (M)

PERCENT OF DERATE

DERATE MULTIPLIER

FACTOR*

0---2000

(0---610)

0

1.00

2001---3000

(610---914)

8--- 12

0.90

3001---4000

(915---1219)

12--- 16

0.86

4001---5000

(1220---1524)

16--- 20

0.82

5001---6000

(1524 ---1829)

20--- 24

0.78

6001---7000

(1829---2134)

24--- 28

0.74

7001---8000

(2134---2438)

28--- 32

0.70

8001---9000

(2439---2743)

32--- 36

0.66

9001---10,000

(2744---3048)

36--- 40

0.62

*Derate multiplier factors are based on midpoint altitude for altitude range.

IN CANADA:

The input rating for altitudes from 2,000 (610 m) to 4,500 ft (1372

m) above sea level must be derated 10% by an authorized Gas

Conversion Station or Dealer.

EXAMPLE:

90,000 Btu/hr Input Furnace Installed at 4300 ft.

Furnace Input Rate at

Sea Level

X Derate Multiplier

Factor

= Furnace Input Rate at

Installation Altitude

90,000

X

0.90

=

81,000

When the gas supply being used has a different heating value or

specific gravity, refer to national and local codes, or contact your

distributor to determine the required orifice size.

UNIT DAMAGE HAZARD

Failure to follow this caution may result in reduced unit

and/or component life.

Do Not redrill an orifice. Improper drilling (burrs,

out--of--round holes, etc.) can cause excessive burner noise

and misdirection of burner flame. If orifice hole appears

damaged or it is suspected to have been redrilled, check

orifice hole with a numbered drill bit of correct size.

!

CAUTION

Adjust Gas Input

The gas input to the unit is determined by measuring the gas flow

at the meter or by measuring the manifold pressure. Measuring the

gas flow at the meter is recommended for natural gas units. The

manifold pressure must be measured to determine the input of

propane gas units.

Measure Gas Flow (Natural Gas Units)

Minor adjustment to the gas flow can be made by changing the

manifold pressure. The manifold pressure must be maintained

between 3.2 and 3.8 in. wc.

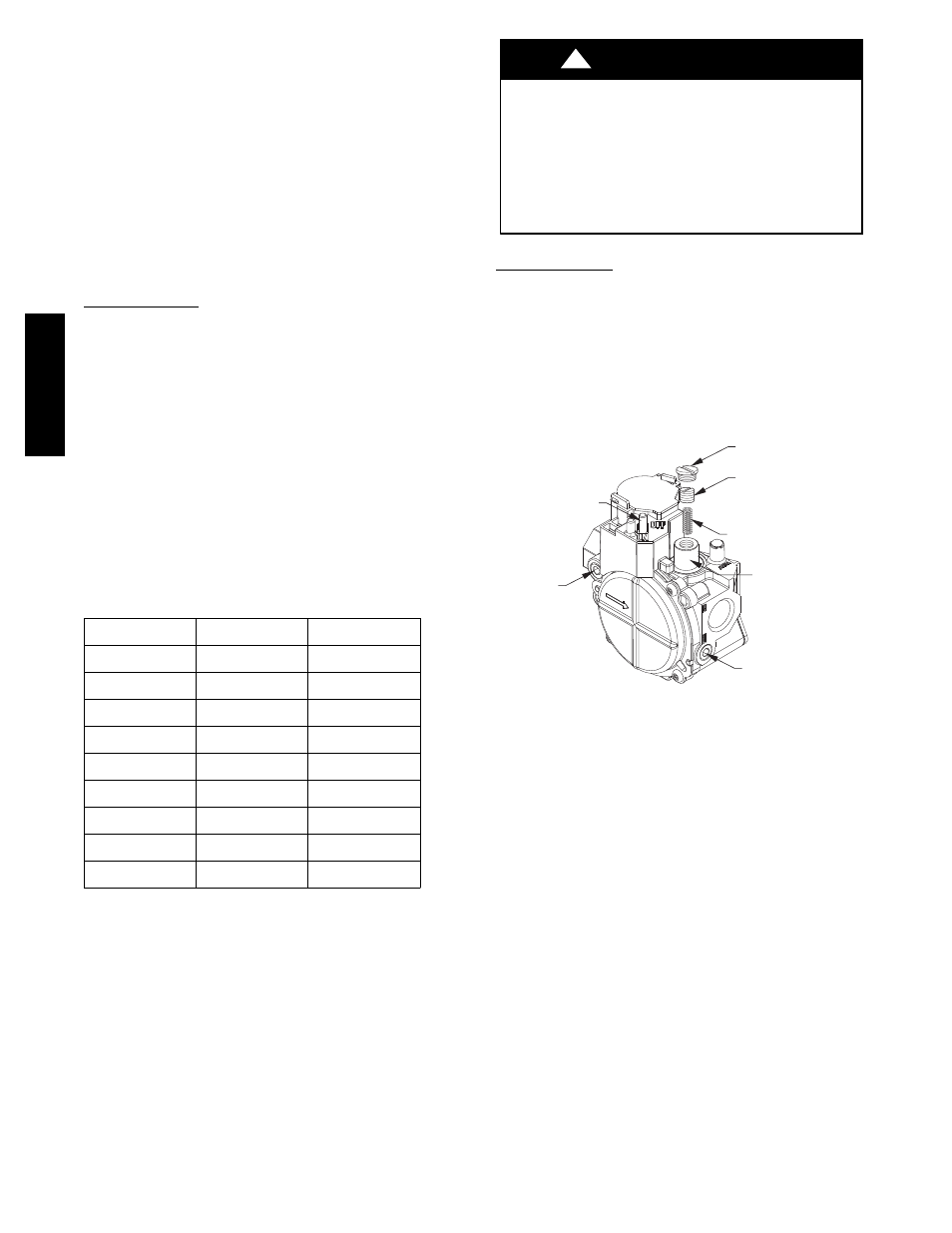

REGULATOR

COVER SCREW

ADJUSTMENT

SCREW

REGULATOR SPRING

(PROPANE - WHITE)

NATURAL - SILVER)

GAS PRESSURE

REGULATOR

ADJUSTMENT

MANIFOLD

PRESSURE TAP

INLET

PRESSURE TAP

ON/OFF SWITCH

PLASTIC

(

A07751

Fig. 14 -- Single--Stage Gas Valve

If larger adjustments are required, change main burner orifices

following the recommendations of national and local codes.

NOTE:

All other appliances that use the same meter must be

turned off when gas flow is measured at the meter.

Proceed as follows:

1. Turn off gas supply to unit.

2. Remove pipe plug on manifold (See Fig. 12) and connect

manometer. Turn on gas supply to unit.

3. Record number of seconds for gas meter test dial to make

one revolution.

4. Divide number of seconds in Step 3 into 3600 (number of

seconds in one hr).

5. Multiply result of Step 4 by the number of cubic feet (cu ft)

shown for one revolution of test dial to obtain cubic feet (cu

ft) of gas flow per hour.

6. Multiply result of Step 5 by Btu heating value of gas to

obtain total measured input in Btuh. Compare this value

with heating input shown in Table 4 (Consult the local gas

supplier if the heating value of gas is not known).

EXAMPLE: Assume that the size of test dial is 1 cu ft, one

revolution takes 32 sec, and the heating value of the gas is 1050

Btu/ft

3

. Proceed as follows:

1. 32 sec. to complete one revolution.

2. 3600 ÷ 32 = 112.5.

3. 112.5 x 1 =112.5 ft

3

of gas flow/hr.

48E

S