Warning – Carrier T--298 User Manual

Page 30

T--298

3-6

3.5.2 Compressor Replacement

Observe the same procedures for rotary compressors

as for reciprocating compressors.

a. Follow all safety codes. Reminder: use protective

goggles, work gloves, and water soaked quenching

cloth.

b. Remove exterior cover. refer to paragraph 3.5.1. Dis-

connect all wiring from the compressor.

c. Apply field--supplied, line--tap--valves to the suction

and discharge lines as close to the compressor as

possible.

d. Recover the refrigerant charge from the unit. After re-

covering, cut the discharge and suction line process

tubes below the tube crimps. If you choose a good

tubing location for cutting the refrigeration lines ini-

tially, the location is easily accessible when making

the final joints.

WARNING

Oil vapor in piping stubs can ignite from

torch flame and cause serious injury. Exer-

cise extreme care when brazing, and keep

brazing cloth and fire extinguisher handy

for emergency use.

e. Connect a nitrogen supply to the unit at one of the line

--tap--valve connectors (5--psig maximum flow), leav-

ing the other connector open to the atmosphere.

Braze angle valves with stubs to each process tube.

f. Remove compressor from unit (3 bolts).

g. Remove line--tap--valves from suction and discharge

lines. Carefully braze the holes closed from where the

line--tap--valves were removed.

h. Clean system: add or replace liquid line filter drier. For

proper cleaning and flushing use a UL approved re-

frigerant recycling system.

i. Install new compressor and braze into place with

field--supplied copper slip couplings.

j.Connect wiring: replace wire terminals if necessary.

k. Proceed with evacuation and charging (15.9 OZ. --

.45 KG R22). Pinch off lines where angle valves were

added. Cut off angle valves above pinch--off , and

braze tubes.

l. Start up unit.

3.5.3 Control Box Assembly Removal

To remove the control box assembly, do the following:

a. Remove exterior cover assembly. Refer to paragraph

3.5.1.

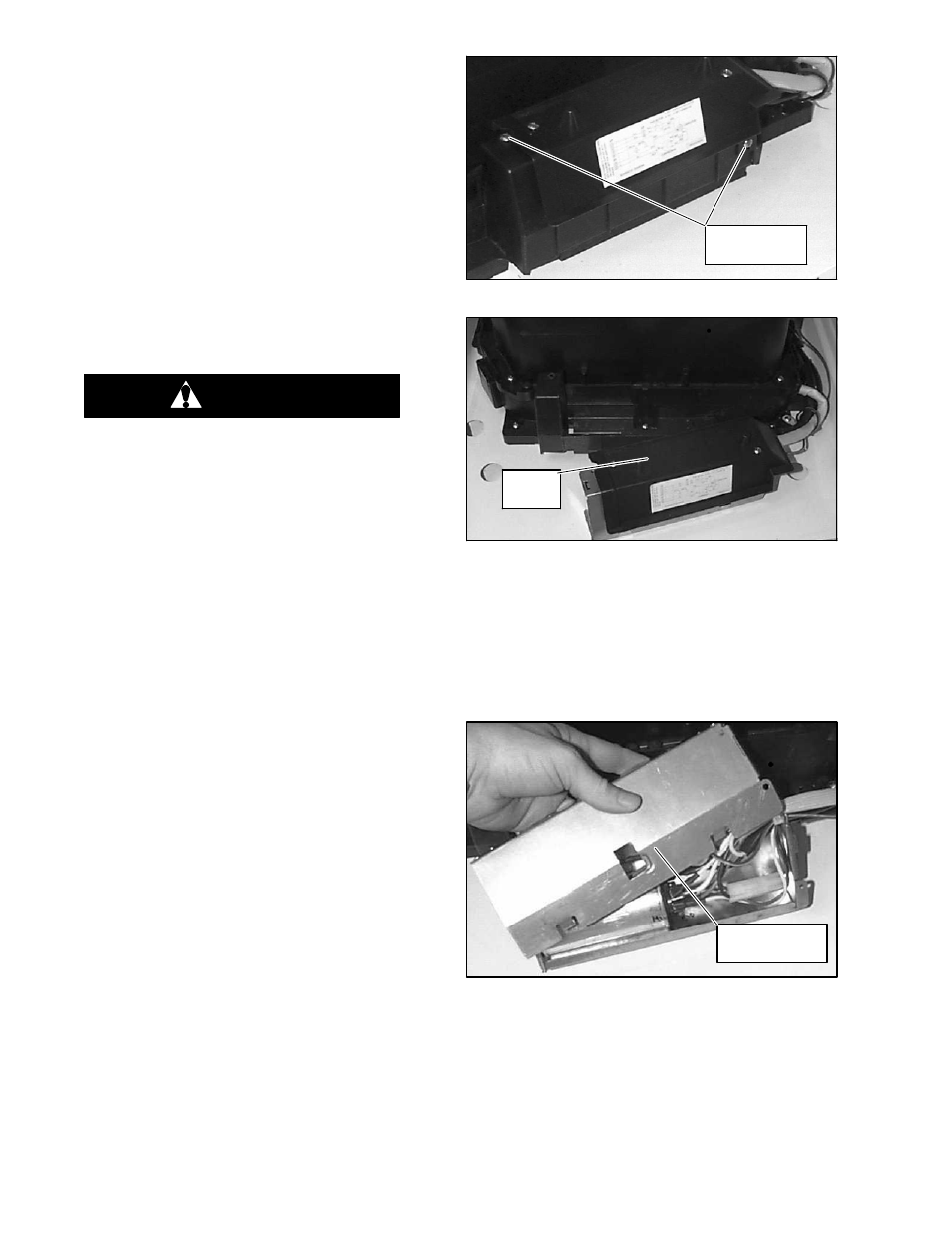

b. Remove 2 screws securing control box assembly to

the lower scroll assembly. (SeeFigure 3-15.)

Control Box

Screws

Figure 3-15 Control Box

Water

Cover

Figure 3-16 Control Box Removal

c. Slide control box out of the lower scroll assembly.

(See Figure 3-16.)

d. To open control box remove 2 screws securing the

water cover to the control box cover.

e. Gently lift the water cover off of the control box. (See

Figure 3-17.)

f. Reverse above procedure for reassembly.

Control Box

Cover

Figure 3-17 Water Cover Removal