Telegram 81 of profile profidrive – Baumer GE-GB-GXxxx User Manual

Page 18

Manual_ProfibusDPV2_BIDE_EN.docx

18/41

Baumer IVO GmbH & Co. KG

22.11.12

Villingen-Schwenningen, Germany

6.3. Telegram 81 of profile PROFIdrive

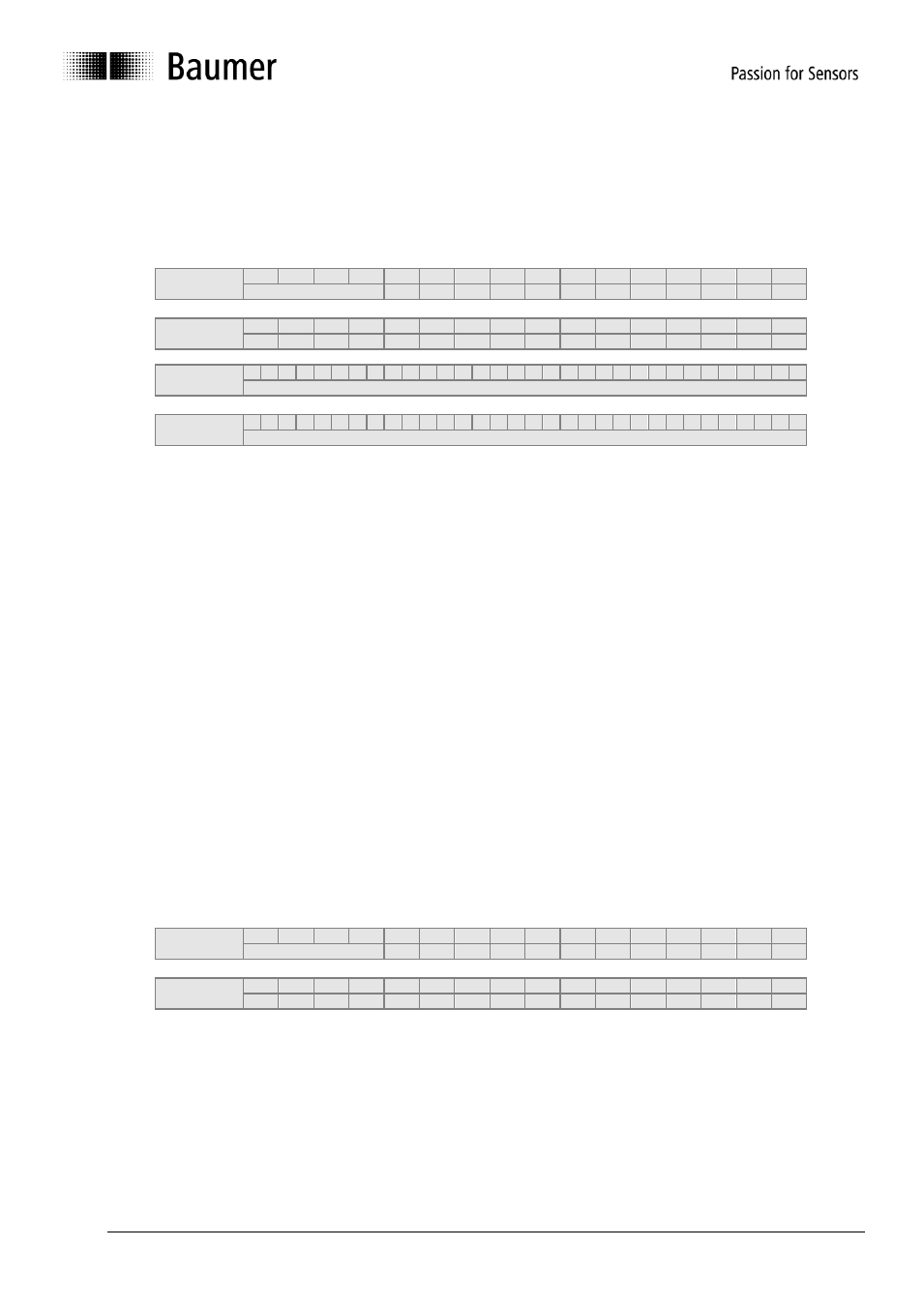

In line with PROFIBUS DP-V2 profile the encoder applies for cyclic communication in clock-synchronous

operation telegram81 of the PROFIdrive profile which means cyclic and clock-synchronous transmission of

12 bytes input data and 4 bytes output data.

Input data

There is a cyclic transmission of input data from encoder to control.

ZSW2

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

Slave Sign-of-Life

0

0

0

0

0

0

0

0

0

0

0

0

G1_ZSW1

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

SE

PS

TA

PA

EA

0

0

0

0

0

0

0

0

0

0

0

G1_XIST1

31

0

encoder position (left-aligned) with / less preset offset

G1_XIST2

31

0

Encoder position (right-aligned) or error message

Bit SE: Sensor Error

If this bit is set, G1_XIST2 will come with an error code instead of the position value

Bit PS: Parking Sensor Active (Acknowledgement)

If this bit is set, the function „Parking Sensor“ will be enabled (error output suppressed)

Bit TA:

Transmit absolute value cyclically (Acknowledgement)

If this bit is set, there will be cyclic position transmission in G1_XIST2.

This always applies to the present encoder.

Bit PA: Preset Acknowledgement

When this bit is set, the preset setting operation at the encoder was successful. The bit

mirrors the preset bit of the output data and is automatically taken back after reset.

Bit EA: Error Acknowledge Required

If this bit is set, an encoder error will have to be acknowledged. This is not general practice

with the present encoder (bit ever 0)

Position data are transmitted by both input double words G1_XIST1 and G1_XIST2. G1_XIST1

comprises the left-aligned position value, e.g. bit 31 = 1 as maximum position value (corresponding to

scaling). G1_XIST2 contains the right-aligned position value in the standard structure. G1_XIST2

further comprises an error code in case of error. The scaling operation always affects both double

words. The effect of the preset on position value G1_XIST1 can be eliminated by parameterization

(„G1_XIST1 affected by Preset“). In this case G1_XIST1 and G1_XIST2 show different position

values. G1_XIST2 is always affected by preset.

Output data

There is a cyclic transmission of output data to the encoder.

STW2

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

Master Sign-of-Life

0

0

0

0

0

0

0

0

0

0

0

0

G1_STW1

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

SEA PS

TA

PR REL

0

0

0

0

0

0

0

0

0

0

0

Bit SEA: Sensor Error Acknowledgement

If this bit is set, the error code in G1_XIST2 will be acknowledged what is not

not necessarily required with the present encoder.

Bit PS: Parking Sensor Active (acknowledgement)

It this bit is set, the function „Parking Sensor“ will be enabled (error output suppressed

Bit TA:

Transmit absolute value cyclically (Acknowledgement)

If this bit is set, there will be a cyclic position transmission in G1_XIST2.

This ever applies to the present encoder, no matter if the bit is set or not.