Terminal assignment, Spa description and explanation – Baumer N 152 User Manual

Page 3

N 152

www.baumer.com

3

1.2. SPA description and explanation

Mounting the spindle position display (SPA) is by docking hollow shaft onto spindle shaft (max.14 mm in

diameter).The hollow shaft is fixed to the spindle shaft by hexagon screw and secured by power grip.

This way, the SPA is mounted in an overhung position and secured against torsion by torque support provided at

rear of the housing. The SPA features an absolute multiturn sensing system capable of detecting the position

after several spindle turns even in powerless state. Position data will be retained even in case of power failure

(min. 10 years).

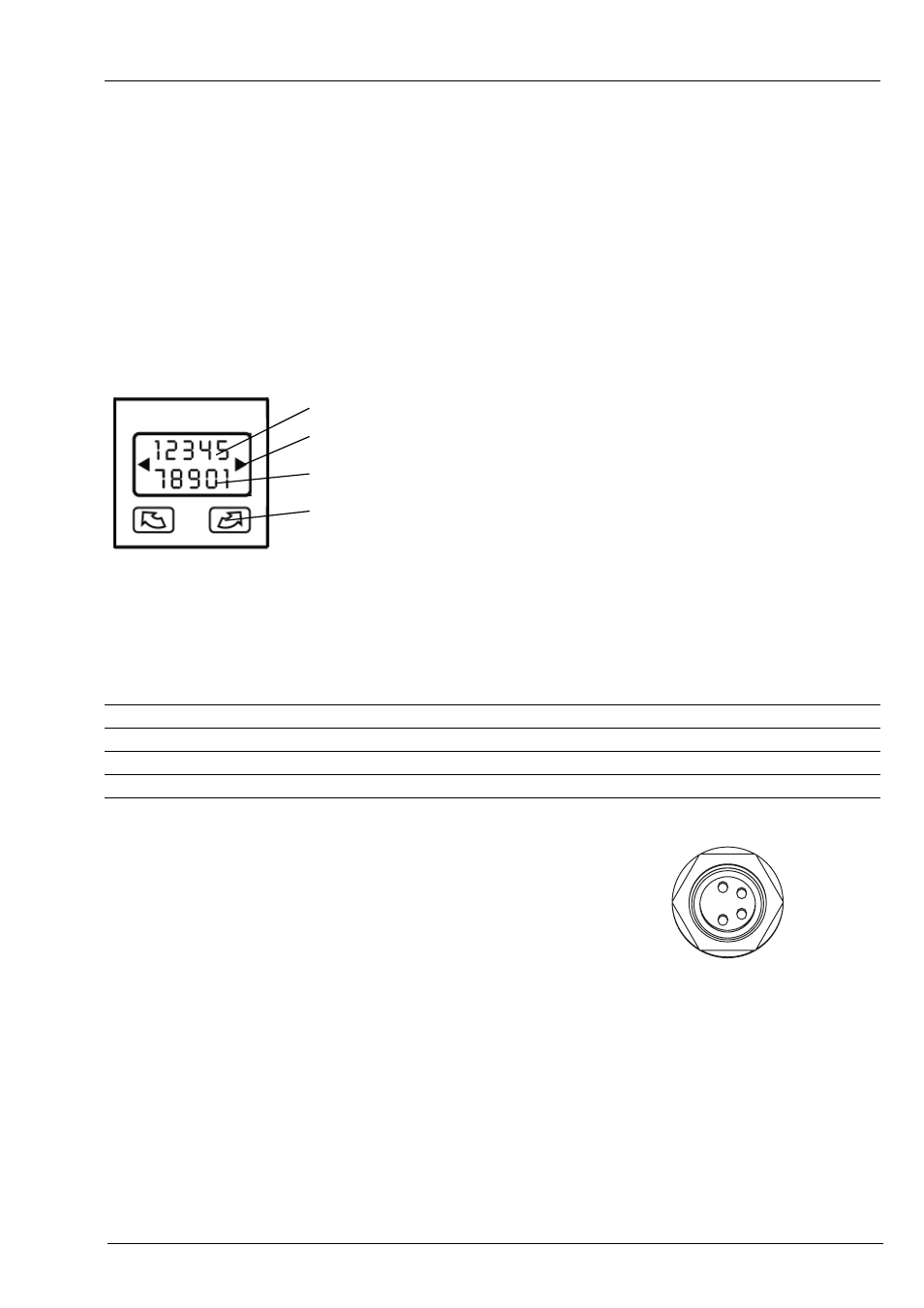

The current position value is indicated in the two-line backlit LCD display (2x 5 digits, numeric), optionally

together with the target transmitted by the control (master). Two arrows indicate the editing engineer the

direction the spindle must be turned to for aligning actual value with target. As soon as actual value is in

alignment with target and within the permitted tolerances, the target will disappear. By corresponding master

parameterization the display can be turned by 180° enabling vertical respectively horizontal installation. SPAs are

networked by M8 connector, power supply is by the same cable directly from master. SPA parameterization by

master only.

indication „target“

arrows indicating the required direction for target/actual value alignment

indication „actual value“

N 152 enables motor connection using the 12-core cable. Two softkeys on the

keypad serve for manual motor trigger. Automated motor trigger by master is

also possible. Motor supply is provided separately.

2. Terminal assignment

Pin Assignment

Core

colour DIN47100

IEC757

Pin 1

Tx/Rx-, RS485

white

orange

Pin 2

Tx/Rx+, RS485

brown

brown

Pin 3

Sensor supply +24 V

yellow

red

Pin 4

Sensor supply 0 V

green

black

Connector

M8

2

4

3

1