2introduction, 3principle of operation – Baumer BA Scatec2 User Manual

Page 3

Manual SCATEC-2

5

Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

2

Introduction

SCATEC-2 has the same key feature as all the other sensors from the SCATEC family: The capability

of non-contact detection of object edges. SCATEC is the sensor of choice when it comes to detect flat

objects conveyed in an overlapping stream or individually. The sensors in the SCATEC family were

developed and highly optimized particularly with regard to the specific demands of non-contact counting

of overlapping paper sheets and newspapers. Therefore the printing industry will be the ideal area of

application for the SCATEC.

Generally speaking a SCATEC sensor reacts to an edge facing the sensor’s laser beam. If the laser

beam strikes such an edge, SCATEC responds with an electrical output pulse of fixed duration.

However, built-in software allows the sensor among other things to suppress the reaction to certain

edges which were identified by the sensor as “false edges”. Therefore, SCATEC-2 makes it possible to

count newspapers to the highest degree of accuracy even at high conveyor speed.

Within the SCATEC family, the SCATEC-2 is characterized by the following properties:

(For details see specifications of the individual Scatec-2 types.)

•

counts edges from a thickness of 0.2 mm and greater

•

optimum working distance: 40 mm or 100 mm

•

intelligent false pulse suppression

•

parameter setting by means of DIP-switches

•

counting rate up to 600,000 copies per hour

•

with interface for remote control and data analysis

Manual SCATEC-2

6

Baumer Electric AG

Version 2011-05

www.baumer.com

Frauenfeld, Switzerland

3

Principle of operation

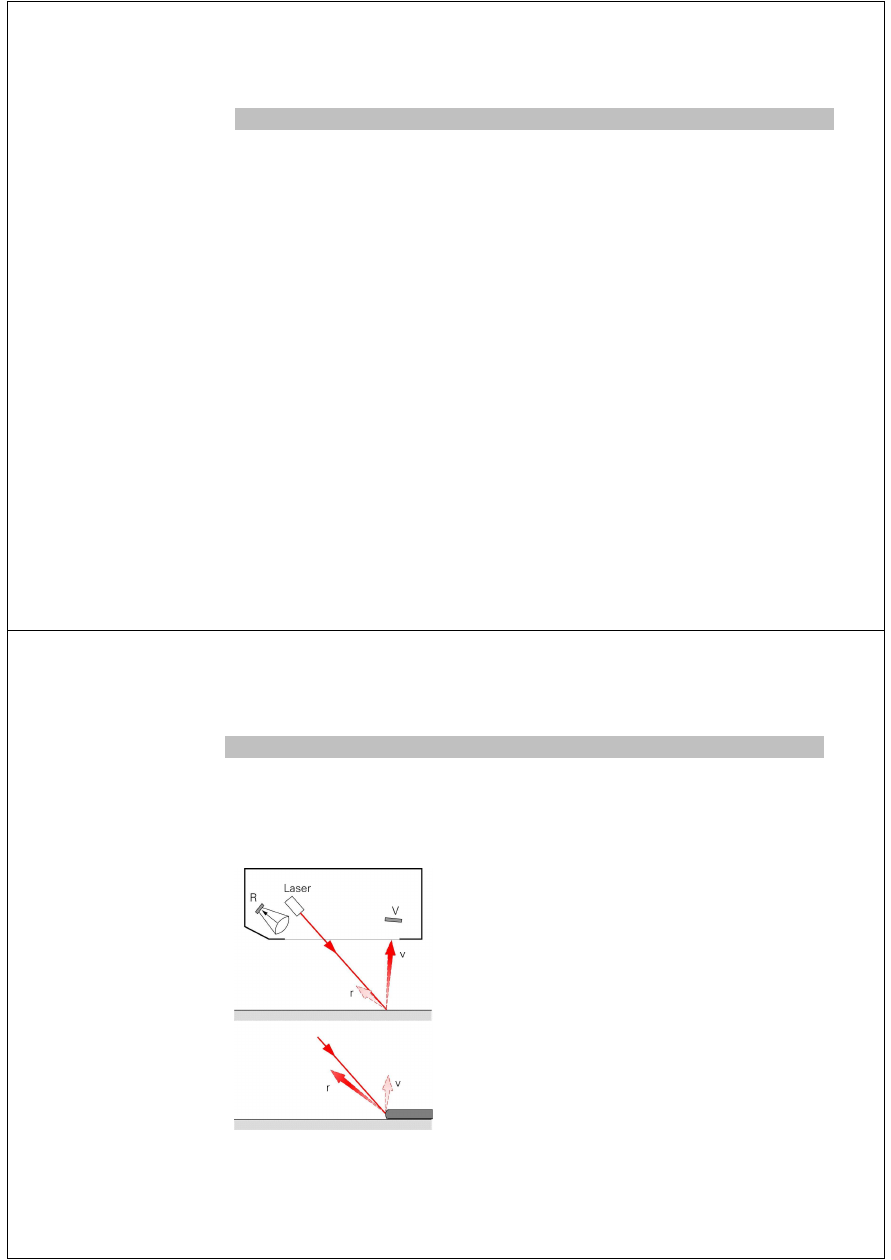

Described simply, the SCATEC-2 consists of a laser light source and two photodetectors. The beam is

aimed diagonally at the objects to be detected. Photodetector R is located close to the laser light source

and photodetector V a little further away. The sensor measures the ratio between signal v (light

scattered forward) and signal r (light scattered backward).

The ratio v/r differs widely depending whether the beam strikes on a flat surface or on an edge. When

an edge moves into the laser beam, the direct line of sight from detector V to the point of contact of the

laser is obstructed, which reduces signal v, and the edge

also increases the backward scattering, causing signal r to

increase. Both effects cause ratio v/r to become

substantially smaller than with a flat surface. If ratio v/r falls

below a specific level, the sensor interprets this as an edge.

This principle of operation clearly demonstrates that:

•

The orientation of the object to the beam is significant.

An edge facing towards the beam creates a small ratio

v/r, in contrast to an edge facing away from the beam.

•

Edge detection is independent of the color, as only the

ratio of the light intensities and not the absolute value

is used for detection.