Mounting of 3a approved products – Baumer Flex Bar HRT User Manual

Page 7

Page 7

Design and specifi cations subject to change without notice

Installation Manual

www.baumerprocess.com

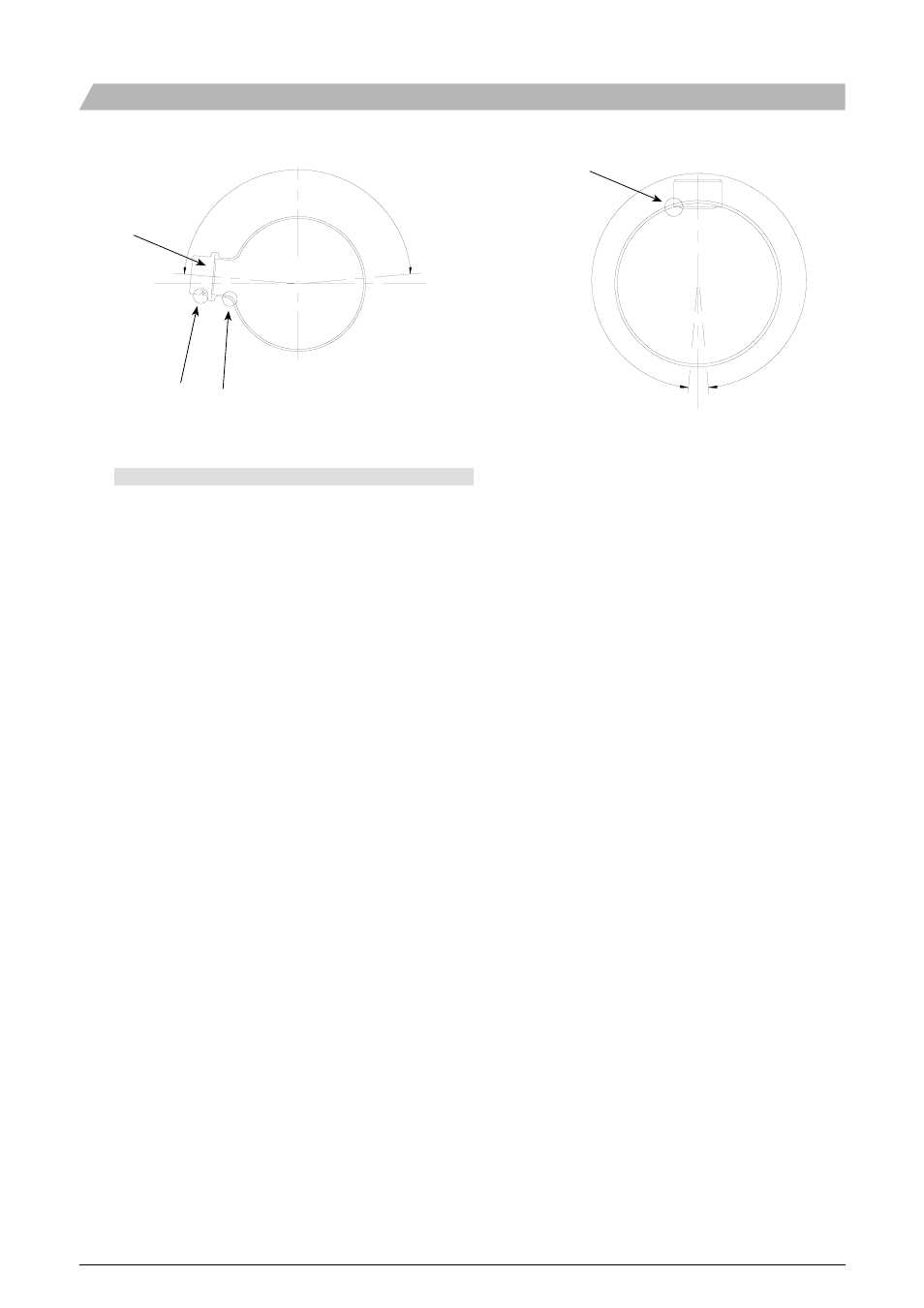

Mounting of 3A Approved Products

Max. ± 85°

Max. ± 175°

5)

1)

2)

3)

4)

Installation of 3A approved products:

1) Use only a 3A approved counter part.

2) The inspection hole should be visible and drained.

3) Mount the instrument in a self drained position.

4) Level the inner surface of the pipe with the counter part.

5) Weldings should be grinded to Ra= 0.8

Refer to the data sheet “FlexBar Accessories” for O-rings, gaskets and

other accessories.

See also other documents in the category Baumer Measuring instruments:

- TA1220 (48 pages)

- TA1200 (36 pages)

- E9xx (2 pages)

- LSP (4 pages)

- TE1 (4 pages)

- CTX (2 pages)

- X9xx (2 pages)

- X5xx (2 pages)

- NE216 (7 pages)

- ISI30 counter (20 pages)

- CombiPress PFMN (12 pages)

- Flex Top 2211 (4 pages)

- NE131 (48 pages)

- TEDM (4 pages)

- TED5 (2 pages)

- FS218 counter (2 pages)

- ME102 counter (2 pages)

- CleverLevel - LFFS (12 pages)

- Flex Top 2221 (4 pages)

- PBSN PBCN (2 pages)

- ME-UE280 counter (2 pages)

- NE215 (40 pages)

- FE504 (2 pages)

- FE-FS304 (2 pages)

- DFOx (4 pages)

- LSKx2x (4 pages)

- TTN6 (2 pages)

- CombiView DFON (8 pages)

- CTL (2 pages)

- CombiLyz AFI4 (36 pages)

- YTED (4 pages)

- CleverLevel - LBFS (8 pages)

- ME230 counter (2 pages)

- CombiTemp (8 pages)

- ED711 (2 pages)

- Flex Bar 3431 (4 pages)