Warning, Step 4 — rig and place unit, Step 5 — select and install ductwork – Carrier 50JZ-A User Manual

Page 6

6

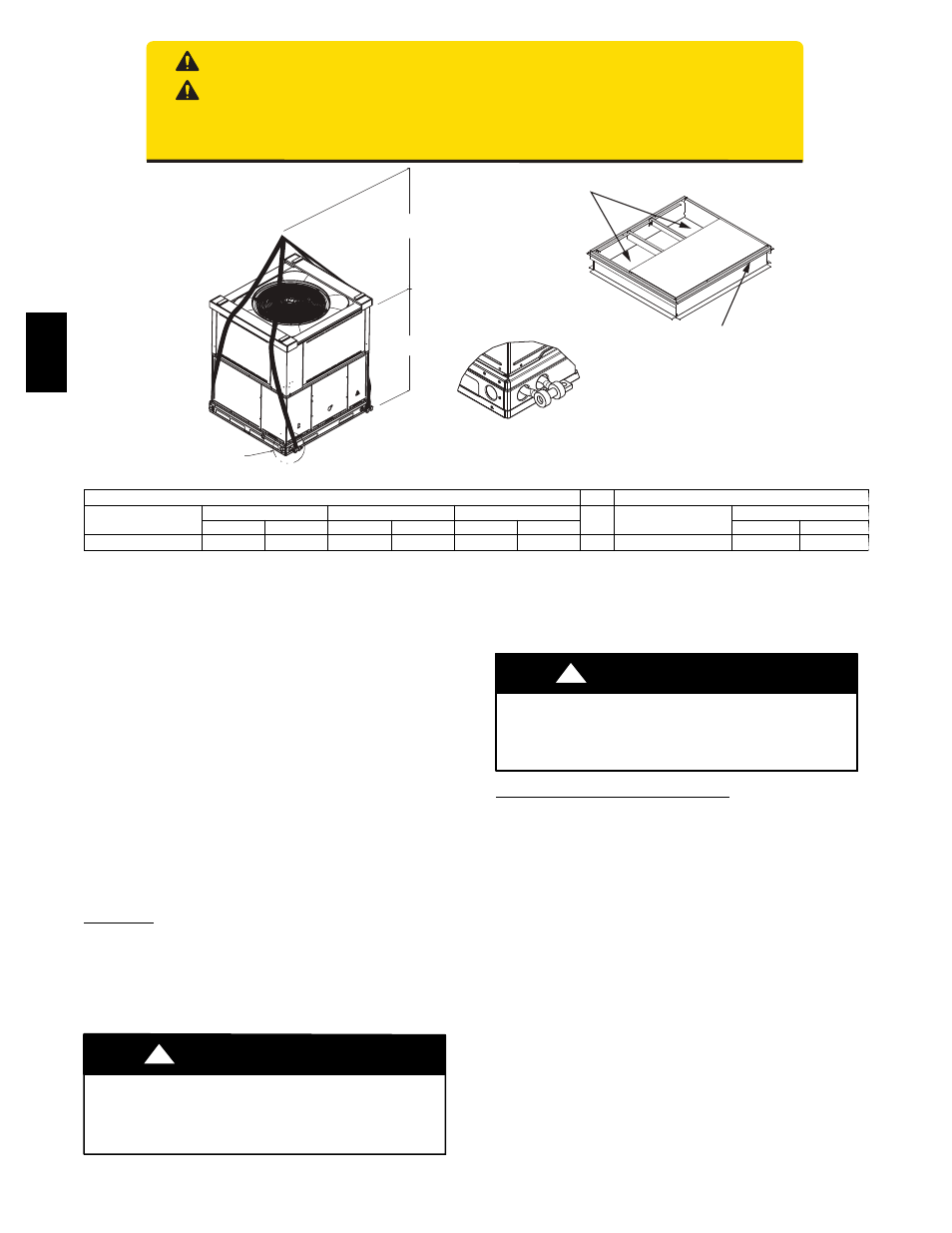

ACCESS PANELS MUST BE IN PLACE WHEN RIGGING.

PANNEAUX D'ACCES DOIT ÊTRE EN PLACE POUR MANIPULATION.

50CY502286 2.0

CAUTION - NOTICE TO RIGGERS

PRUDENCE - AVIS AUX MANIPULATEUR

Use top skid as spreader bar. / Utiliser la palette du haut comme barre de répartition

SEAL STRIP MUST BE IN

PLACE BEFORE PLACING

UNIT ON ROOF CURB

DUCTS

DETAIL A

VOIR DÉTAIL A

MINIMUM HEIGHT: 36" (914.4 mm)

HAUTEUR MINIMUM

UNIT HEIGHT

HAUTEUR D'UNITÉ

SEE DETAIL A

VOIR DÉTAIL A

BANDE SCELLANT DOIT ÊTRE

EN PLACE AVANT DE PLACER

L'UNITÉ SUR LA BASE DE TOIT

A09051

RIGGING WEIGHTS (SMALL CABINET)

RIGGING WEIGHTS (LARGE CABINET)

Unit

24

30

36

Unit

48

lb

kg

lb

kg

lb

kg

lb

kg

Rigging Weight

314

142.4

335

152.0

343

155.6

Rigging Weight

373

169.2

NOTE: See dimensional drawing for corner weight distribution.

Fig. 6 -- Rigging Weights

Step 4 — Rig and Place Unit

Rigging and handling of this equipment can be hazardous for

many reasons due to the installation location (roofs, elevated

structures, etc.).

Only trained, qualified crane operators and ground support staff

should handle and install this equipment.

When working with this equipment, observe precautions in the

literature, on tags, stickers, and labels attached to the equipment,

and any other safety precautions that might apply.

Training for operators of the lifting equipment should include, but

not be limited to, the following:

1. Application of the lifter to the load, and adjustment of the

lifts to adapt to various sizes or kinds of loads.

2. Instruction in any special operation or precaution.

3. Condition of the load as it relates to operation of the lifting

kit, such as balance, temperature, etc.

Follow all applicable safety codes. Wear safety shoes and work

gloves.

Inspection

Prior to initial use, and at monthly intervals, all rigging shackles,

clevis pins, and straps should be visually inspected for any damage,

evidence of wear, structural deformation, or cracks. Particular

attention should be paid to excessive wear at hoist hooking points

and load support areas. Materials showing any kind of wear in

these areas must not be used and should be discarded.

UNIT FALLING HAZARD

Failure to follow this warning could result in personal

injury or death.

Never stand beneath rigged units or lift over people.

!

WARNING

1. Leave top shipping skid on the unit for use as a spreader bar

to prevent the rigging straps from damaging the unit. If the

skid is not available, use a spreader bar of sufficient length

to protect the unit from damage.

PROPERTY DAMAGE HAZARD

Failure to follow this warning could result in personal injury.

When straps are taut, the clevis should be a minimum of 36

in. (914 mm) above the unit top cover.

!

WARNING

Rigging/Lifting of Unit (See Fig. 6)

Lifting holes are provided in base rails as shown.

1. Attach shackles, clevis pins, and straps to the base rails of

the unit. Be sure materials are rated to hold the weight of the

unit (See Fig. 6).

2. Attach a clevis of sufficient strength in the middle of the

straps. Adjust the clevis location to ensure unit is lifted level

with the ground.

After the unit is placed on the roof curb or mounting pad, remove

the top skid.

Step 5 — Select and Install Ductwork

The design and installation of the duct system must be in

accordance with the standards of the NFPA for installation of

non--residence type air conditioning and ventilating systems,

NFPA 90A or residence--type, NFPA 90B and/or local codes and

ordinances.

Select and size ductwork, supply--air registers, and return air grilles

according to ASHRAE (American Society of Heating,

Refrigeration, and Air Conditioning Engineers) recommendations.

The unit has duct flanges on the supply-- and return--air openings

on the side of the unit.

50J

Z

--

A