Fasteners, Ratchet drive (8 row only), Finger pickup meter – Great Plains PT8030 V1013 Operator Manual User Manual

Page 38

36

Section 5 Maintenance and Lubrication

10/10/12

PT6030 and PT8030 Pull-Type Planter 401-032M-A

Great Plains Mfg., Inc.

2.

If the shafts are not aligned, adjust the contact-drive

tower. Loosen the mounting bolts (1) on both sides of

the tower. Adjust tower position until shafts are

aligned.

16849

1

1

Figure 5-4

Contact Drive Housing Adjustment

3.

Retighten tower mounting bolts. Slide coupler sleeve

over transmission-input shaft and re-insert cotter pin.

4.

Level the transmission-output shaft. Place a straight

edge across the 7-by-7-inch frame tube. Take a mea-

surement from the straight edge (1) down to the top of

the shaft (2). Repeat measurement at each row unit.

Measurements must be equal across the planter.

To level the shaft, loosen the shaft hanger bearings (3)

at each row unit. Adjust shaft until measurements are

equal across the planter.

16833

1

2

3

Figure 5-5

Leveling Transmission-Output Shaft

Fasteners

When working on the planter torque all bolts, screws and

nuts to the correct values listed on Torque Values Chart,

“Appendix” on page

52. Check latches and other fasten-

ers on the planter to prevent failures in the field.

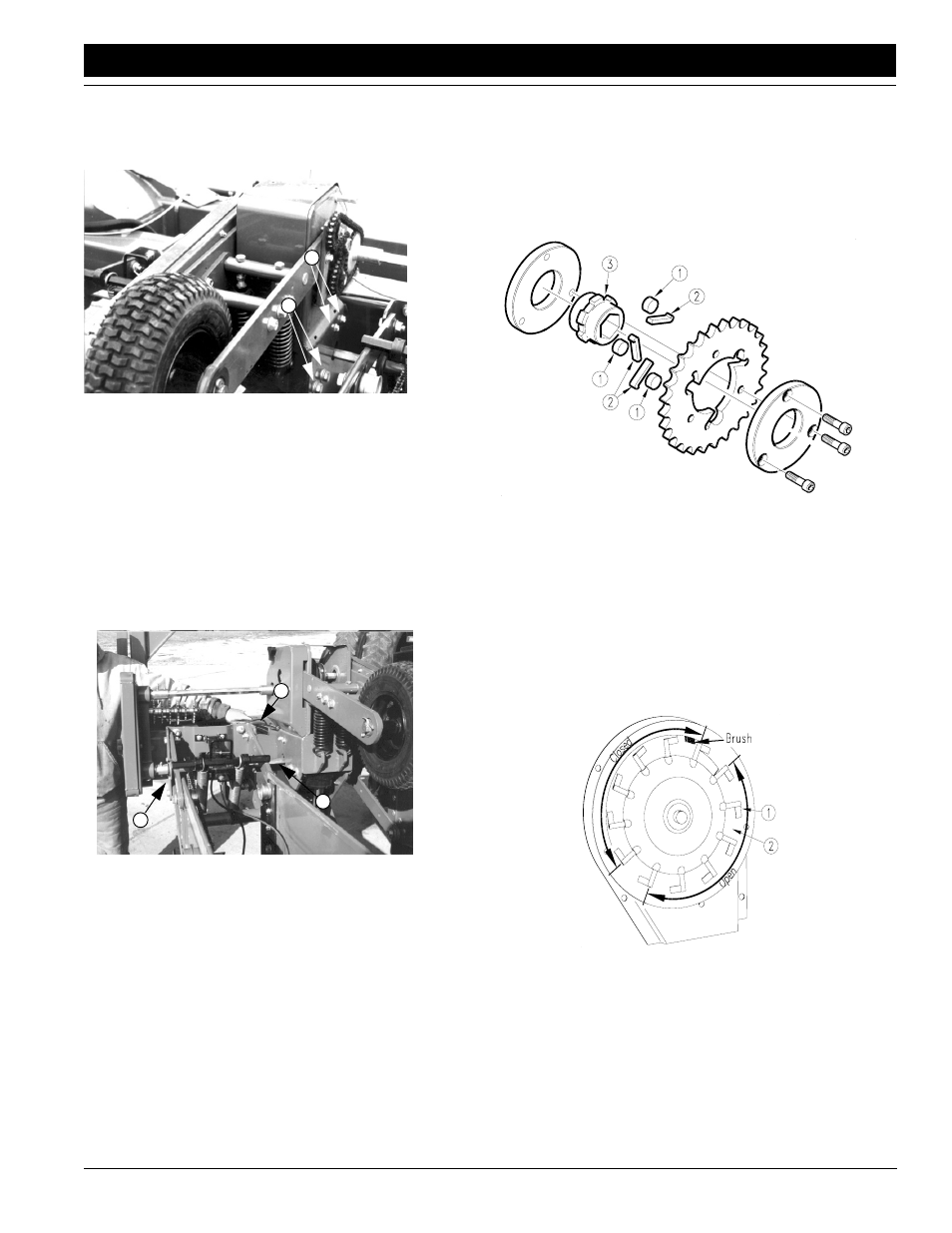

Ratchet Drive (8 Row Only)

The ratchet assembly must operate freely and the springs

(1) must bring the dogs (2) back against the ratchet hub

(3).

Repack with grease annually.

15177

Figure 5-6

Ratchet Drive

Finger Pickup Meter

Inspect and repair the finger pickup meter by removing the

two bolts holding the meter to the hopper. Remove the

three bolts on the meter baffle to gain access to the finger

mechanism.

Rotate the meter input shaft by hand to check the fingers.

The fingers should be against the carrier plate in the area

shown closed and raised in the area shown open in Figure

5-7.

Figure 5-7

Finger Raised/Location of Brush

12353