Marker width, Tire scraper, Meter drive adjustments – Great Plains PT8030 V1013 Operator Manual User Manual

Page 32: Check vertical alignment, Check horizontal alignment

30

Section 3 Adjustments

10/10/12

PT6030 and PT8030 Pull-Type Planter 401-032M-A

Great Plains Mfg., Inc.

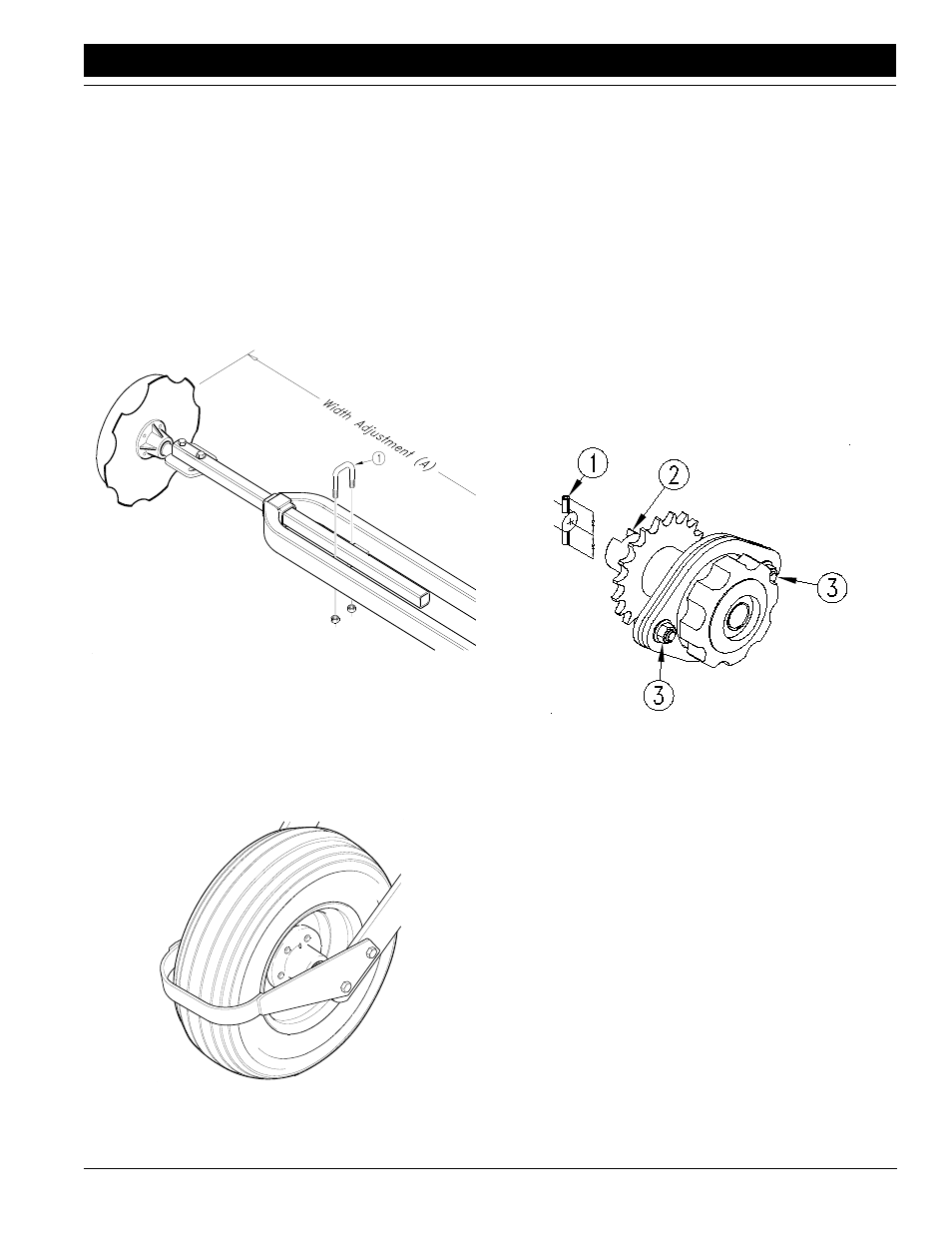

Marker Width

Refer to Figure 3-19.

To adjust marker width, loosen the marker tube u-bolt (1)

and slide it in or out to the desired width. After adjusting,

retighten the u-bolt.

Dimension (A) is measured from the center line of the

planting unit to the marker disk. The dimensions provided

are approximate. After adjusting, field check the actual di-

mension.

For 6-row, 30 inch rows, A = 180 inches.

For 8-row, 30 inch rows, A = 240 inches.

Figure 3-19

Marker Disk Adjustment

15835

Tire Scraper

In some soil types, you may need to use optional tire

scrapers. The scrapers prevent excess mud from building

up on the transport tires so the contract-drive tire can op-

erate properly. Adjust the scraper so it does not contact

the tire. See Figure 3-20.

Figure 3-20

Tire Scraper

15027

Meter Drive Adjustments

The alignment between the meter clutch and the input

shaft on both the seed and chemical hoppers is important.

If there is misalignment, the meters will not function prop-

erly. Excessive wear and damage can also occur to the

meter housings. When replacing the meters, check the

vertical and horizontal alignment.

Check Vertical Alignment

Refer to Figure 3-21.

1.

Latch the hopper into place on the support.

2.

Check that the roll pin (1) in the end of the input shaft

is centered so equal amounts of the roll pin protrude

from both sides of the shaft.

3.

Rotate the input shaft so the roll pin is vertical.

4.

Rotate the drive coupler (2) so the slots are vertical.

5.

Release the clutch to engage the drive coupler with

the input shaft.

16869

Figure 3-21

Vertical Alignment

6.

If the alignment is correct, the coupler will engage with

the shaft freely and the roll pin will extend equally on

each side of the coupler. If not, adjust alignment as ex-

plained under Meter Drive Alignment, this page.

Check Horizontal Alignment

1.

Latch the hopper into place on the support.

2.

Check that the roll pin in the end of the input shaft is

centered so equal amounts of the roll pin protrude

from both sides of the shaft.

3.

Rotate the input shaft so the roll pin is horizontal.

4.

Rotate the drive coupler so the slots are horizontal.

5.

Release the clutch to engage the drive coupler with

the input shaft.

6.

If the alignment is correct, the coupler will engage with

the shaft freely and the roll pin will extend equally on

each side of the coupler. If not, adjust alignment as ex-

plained under Meter Drive Alignment, this page.