Section 4 troubleshooting, Troubleshooting – Great Plains PT8030 V1013 Operator Manual User Manual

Page 34

32

Section 4 Troubleshooting

10/10/12

PT6030 and PT8030 Pull-Type Planter 401-032M-A

Great Plains Mfg., Inc.

Section 4

Troubleshooting

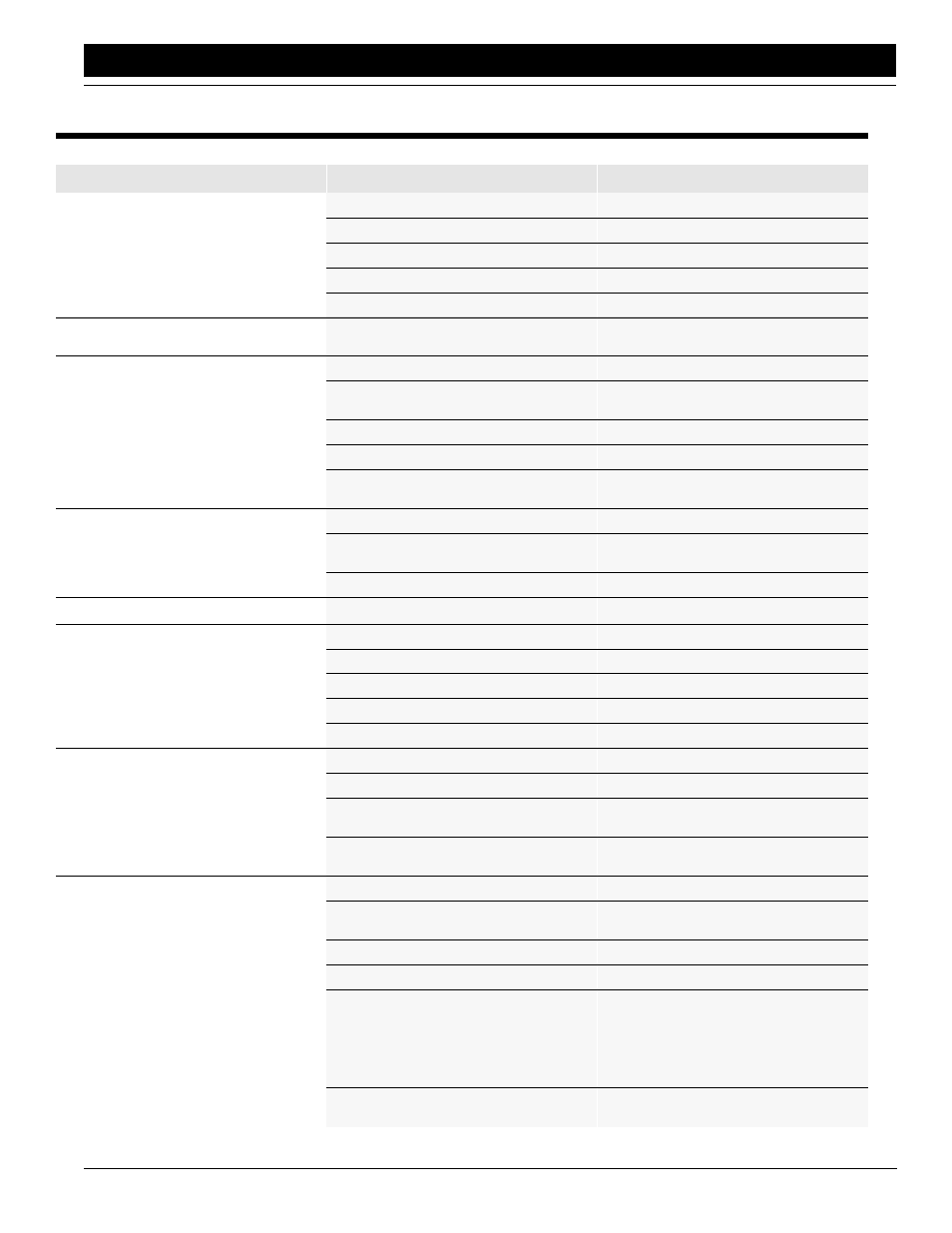

Problem

Possible Cause

Solution

One row not planting seed.

Drive clutch release not engaged.

Engaged clutch release mechanism.

Foreign material in hopper.

Clean hopper and finger carrier mechanism.

Seed hopper empty.

Fill seed hopper.

Row unit drive chain off of sprocket or broken.

Repair or replace drive chain.

Drive not functioning.

Inspect all drives.

Drive release does not engage properly.

Drive release shaft isn’t aligned properly with

meter drive shaft.

Align drive mechanism. See “Meter Drive

Adjustment”.

Unit is skipping.

Foreign material or obstruction in meter.

Clean out and inspect.

Finger holder improperly adjusted.

Adjust to proper setting. (22 to 25 inch pounds

torque)

Loose finger holder.

Adjust tension of finger pickup.

Broken fingers.

Replace fingers and/or springs as required.

Planting too slowly.

Increase planting speed to within recom-

mended range. See charts for correct speed.

Planting too many doubles.

Planting too fast.

Stay within recommended range.

Lose finger holder.

Adjust to specifications (22 to 24 inch pounds

torque)

Worn brush in carrier plate.

Inspect and replace if necessary.

Over planting.

Worn carrier plate.

Inspect and replace if necessary.

Under planting.

Belt installed backwards.

Remove and install correctly.

Weak springs.

Replace.

Spring not properly installed.

Remove finger holder and correct.

Seed belt catching or dragging.

Replace belt.

Brush dislodging seed.

Replace brush.

Irregular or incorrect seed spacing.

Driving too fast.

Check chart for correct speed.

Wrong tire pressure.

Inflate tires to correct air pressure.

Drive wheels slipping.

Reduce down pressure on row unit down force

springs.

Wrong sprockets.

Check planting rate charts for correct sprocket

combinations.

Seed spacing not as indicated in charts.

Wrong tire pressure.

Inflate tires to correct air pressure.

Inconsistent seed size.

Do field check and adjust sprockets accord-

ingly.

Wrong sprockets.

Check chart for correct sprocket combination.

Excessive unit bounce.

Reduce ground speed when planting.

Excessive contact-drive-wheel slippage

Check for poorly lubricated parts, misaligned

bearings or caked material in chemical hop-

pers.

Consider removing optional attachments that

remove frame weight from the drive wheels

and contribute to drive-wheel slippage.

Charts are approximate.

Slight variations due to wear may produce

seed spacing variations.